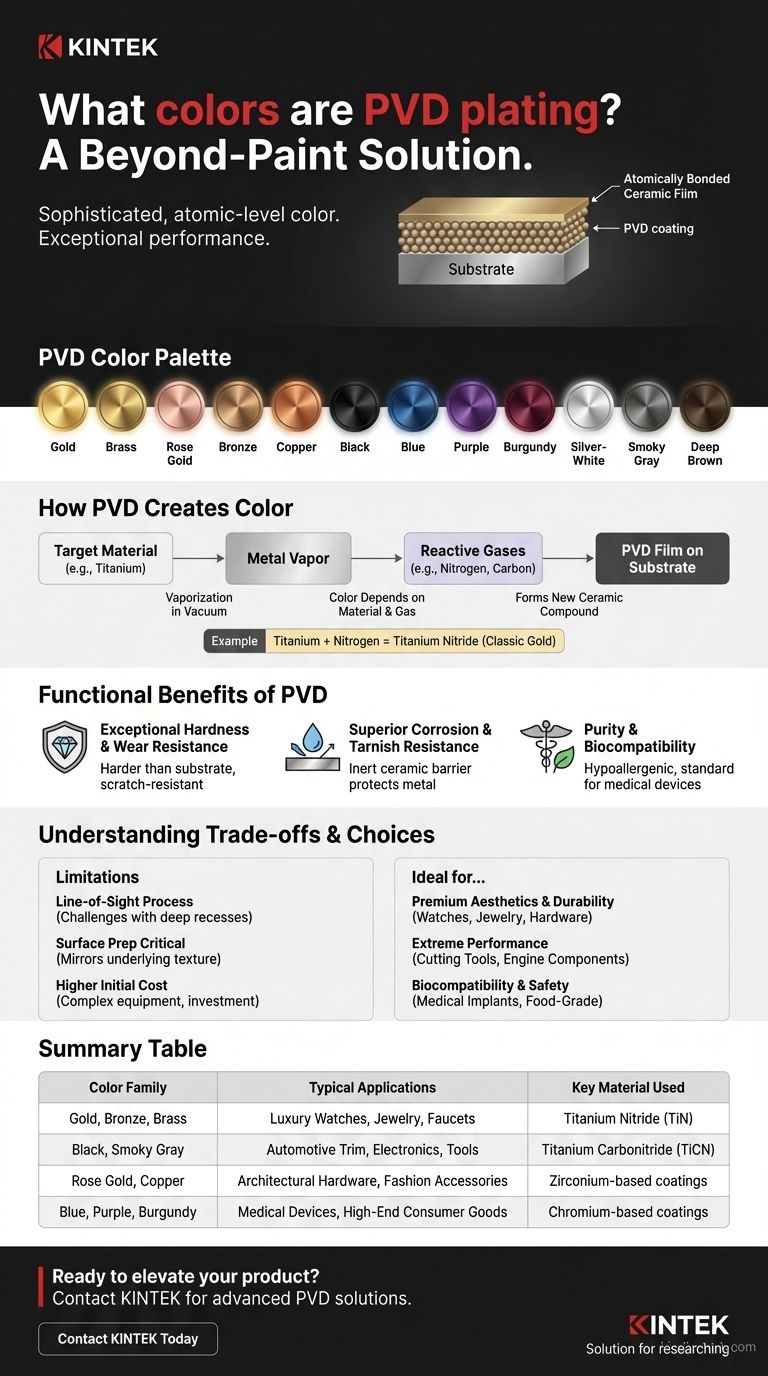

Beyond a simple layer of paint, Physical Vapor Deposition (PVD) coatings provide a wide and sophisticated color palette through an advanced metallurgical process. PVD can produce a range of metallic finishes including various shades of gold, brass, rose gold, bronze, copper, and black. It can also create more vibrant hues like blue, purple, and burgundy, as well as neutral tones like silver-white, smoky gray, and deep brown.

The crucial takeaway is that PVD colors are not applied to a surface, but are atomically bonded with it. This creates a thin, ceramic-based film where the color is an integral part of the finish, resulting in exceptional durability, hardness, and corrosion resistance that far surpasses traditional painting or plating.

How PVD Creates Color

Unlike paint, which is a liquid coating that dries on a surface, PVD is a vacuum deposition process. It works by vaporizing a solid metal (the "target") in a vacuum chamber and depositing it as a thin, atomic-level film onto the substrate. The color is determined by the specific material used and the reactive gases introduced during this process.

The Role of Target Materials

The choice of the source material vaporized in the PVD chamber forms the basis of the coating. Materials like titanium, zirconium, and chromium are common starting points for different color families. For example, titanium is often the foundation for gold and black tones.

The Impact of Reactive Gases

To create specific colors, reactive gases like nitrogen, carbon, or oxygen are precisely introduced into the vacuum chamber. These gases combine with the vaporized metal atoms as they deposit on the surface, forming a new ceramic compound with unique properties and a distinct color.

For example, introducing nitrogen to titanium vapor creates Titanium Nitride (TiN), which has a classic gold color. Modifying the gas mixture can create Titanium Carbonitride (TiCN), which appears as bronze or brown.

Not a Paint, But a Bonded Film

This process means the color is not a separate layer that can easily chip, flake, or peel. It is an extremely hard, ceramic film that is chemically and physically bonded to the metal underneath, essentially becoming the new top layer of the surface itself.

Beyond Aesthetics: The Functional Benefits of PVD

The reason PVD is chosen for high-performance applications is because the color is just one aspect of a fundamentally superior surface. The process that creates the color also imparts significant functional advantages.

Exceptional Hardness and Wear Resistance

PVD coatings are often harder than the substrate material itself. This makes the surface highly resistant to scratches, abrasion, and daily wear, which is why it's a preferred finish for watches, high-end faucets, and tools.

Superior Corrosion and Tarnish Resistance

The ceramic film created by PVD is chemically inert and highly dense. This provides a robust barrier that protects the underlying metal from oxidation, tarnish, and corrosion caused by moisture, salts, and other environmental factors.

Purity and Biocompatibility

PVD is an exceptionally clean and pure process, producing coatings with excellent adhesion and uniformity. Many PVD coatings, particularly those based on titanium, are biocompatible and hypoallergenic, making them the standard for medical implants and surgical tools.

Understanding the Trade-offs

While PVD is a superior technology, it's important to understand its specific requirements and limitations to determine if it's right for your application.

It's a Line-of-Sight Process

Because the vaporized material travels in a straight line within the vacuum chamber, PVD has difficulty coating deep recesses or complex internal geometries. Parts must often be rotated on complex fixtures to ensure even coverage.

Surface Preparation is Critical

The final PVD finish is a direct reflection of the underlying surface. A highly polished part will result in a bright, polished PVD finish, while a brushed or bead-blasted part will result in a matte PVD finish. Any surface imperfections will be preserved, not hidden.

Higher Initial Cost

PVD equipment is a significant capital investment, and the process is more complex than traditional electroplating or painting. This can result in a higher per-piece cost, which is typically justified by the product's vastly extended lifespan and superior performance.

Making the Right Choice for Your Product

Your goal should dictate your finishing choice. PVD excels when longevity and performance are as important as aesthetics.

- If your primary focus is premium aesthetics and durability: PVD is the ideal choice for products like luxury watches, jewelry, architectural hardware, and high-end electronics where a finish must look new for years.

- If your primary focus is extreme performance: PVD is the industry standard for cutting tools, engine components, and industrial equipment where hardness and lubricity are critical and the color is a secondary benefit.

- If your primary focus is biocompatibility and safety: PVD is the definitive solution for medical implants, surgical instruments, and food-grade equipment due to its inert and non-toxic nature.

Ultimately, choosing a PVD finish is a decision to invest in a surface where color and performance are one and the same.

Summary Table:

| Common PVD Color Families | Typical Applications | Key Material Used |

|---|---|---|

| Gold, Bronze, Brass | Luxury Watches, Jewelry, Faucets | Titanium Nitride (TiN) |

| Black, Smoky Gray | Automotive Trim, Electronics, Tools | Titanium Carbonitride (TiCN) |

| Rose Gold, Copper | Architectural Hardware, Fashion Accessories | Zirconium-based coatings |

| Blue, Purple, Burgundy | Medical Devices, High-End Consumer Goods | Chromium-based coatings |

Ready to elevate your product with a PVD finish that combines stunning aesthetics with superior durability?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment, medical devices, and high-performance industrial components. Our expertise ensures your products benefit from:

- Exceptional wear and corrosion resistance for longer product lifecycles

- Biocompatible and hypoallergenic finishes perfect for medical and food-grade applications

- Vibrant, consistent colors that won't chip, fade, or tarnish

Let our team help you select the ideal PVD coating for your specific needs. Contact KINTEK today to discuss your project and receive a customized solution quote!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process