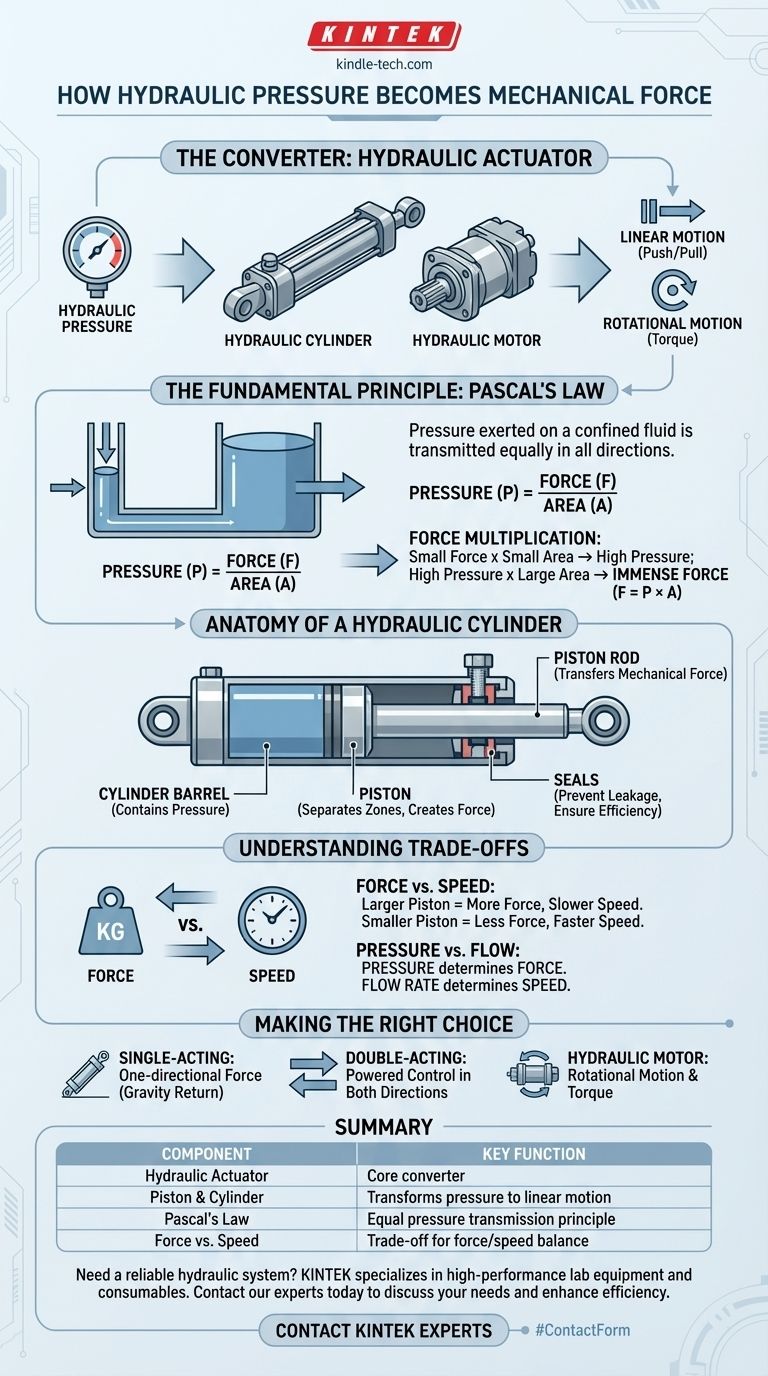

At its core, the component that converts hydraulic pressure into mechanical force is a hydraulic actuator. The most common and recognizable type of hydraulic actuator is the hydraulic cylinder, which produces linear motion (pushing or pulling), but this category also includes hydraulic motors that produce rotary motion.

Hydraulic systems operate on the principle of force transfer and multiplication. The actuator is the final, crucial component that translates the potential energy stored in a pressurized, incompressible fluid into useful work.

The Fundamental Principle: Pascal's Law

The entire field of hydraulics is built upon a simple physical law that governs the behavior of confined fluids. Understanding this is key to understanding how an actuator works.

Pascal's Law Explained

Pascal's Law states that when there is an increase in pressure at any point in a confined fluid, there is an equal increase at every other point in the container.

The formula is simple: Pressure (P) = Force (F) / Area (A). This means the force exerted is a direct product of the fluid pressure and the surface area it acts upon.

How an Actuator Applies This Law

A hydraulic cylinder is essentially a sealed tube with a piston inside. When pressurized hydraulic fluid is pumped into one side of the cylinder, it pushes against the face of the piston.

This pressure exerts a force on the piston's surface area. Because the piston is connected to a rod, that force is transferred out of the cylinder as a linear mechanical force.

Force Multiplication: The Core Advantage

The true power of hydraulics comes from force multiplication. By applying a small force to a small area in the system (e.g., at the pump), you can generate immense pressure.

When that same pressure is applied to a large surface area (like the face of a large piston in a cylinder), the resulting output force is magnified significantly (F = P * A). This allows compact systems to move incredibly heavy loads.

Anatomy of a Hydraulic Cylinder

While designs vary, nearly all linear actuators share a few critical components that work together to translate pressure into motion.

The Cylinder Barrel

This is the main body of the actuator. It must be strong enough to contain the high pressures of the hydraulic fluid without deforming. Its inner surface is honed to a smooth finish to allow the seals to work effectively.

The Piston

The piston is a disc that moves back and forth inside the cylinder barrel. It separates the two pressure zones within the cylinder, allowing pressure to build on one side and push the piston.

The Piston Rod

This is the polished shaft connected to the piston that extends out from the cylinder. It is the component that transfers the mechanical force generated by the piston to the external load.

The Seals

Seals are arguably the most critical components for performance. They prevent internal and external leakage. The piston seal prevents fluid from bypassing the piston, while the rod seal prevents fluid from leaking out of the cylinder around the rod.

Understanding the Trade-offs

Choosing or designing a hydraulic system is a game of balancing competing factors. The actuator is at the center of these trade-offs.

Force vs. Speed

For a given hydraulic pump (which provides a set fluid flow rate), there is an inverse relationship between the actuator's force and its speed.

A cylinder with a large piston diameter will generate immense force but will move slowly because it requires a large volume of fluid to travel a certain distance. A small-diameter cylinder will move much faster but generate less force.

Pressure vs. Flow

It is a common misconception that pressure and flow are linked. They are independent variables.

Pressure determines force. A system's maximum pressure rating dictates the maximum force an actuator can produce.

Flow rate determines speed. The volume of fluid supplied to the actuator per minute (GPM or L/min) dictates how fast the piston rod will extend or retract.

System Inefficiencies

In the real world, no system is 100% efficient. Friction from seals, fluid turbulence, and slight fluid compression all generate heat. This represents an energy loss that must be managed, often with hydraulic coolers.

Making the Right Choice for Your Goal

Selecting an actuator requires a clear understanding of your primary objective.

- If your primary focus is simple, one-directional force: A single-acting cylinder, which uses hydraulic pressure to extend and an external force (like gravity or a spring) to retract, is the most cost-effective solution.

- If your primary focus is powered control in both directions: A double-acting cylinder, which has ports for fluid to act on both sides of the piston, is necessary for both powered extension and retraction.

- If your primary focus is generating rotational motion: A hydraulic motor is the correct actuator to convert hydraulic pressure and flow into torque and rotational speed.

Understanding how an actuator translates fluid pressure into mechanical force is the key to harnessing the immense power and flexibility of hydraulic systems.

Summary Table:

| Component | Key Function |

|---|---|

| Hydraulic Actuator | Core device converting pressure into mechanical force. |

| Piston & Cylinder | Transforms fluid pressure into linear motion (push/pull). |

| Pascal's Law | Fundamental principle: Pressure is transmitted equally in a confined fluid. |

| Force vs. Speed | Key trade-off: Larger piston area = more force, slower speed. |

Need a reliable hydraulic system for your lab or industrial equipment? KINTEK specializes in high-performance lab equipment and consumables. Our expertise ensures you get the precise force and motion control your application demands. Contact our experts today to discuss your specific hydraulic needs and enhance your system's efficiency and power.

Visual Guide

Related Products

- Variable Speed Peristaltic Pump

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- How does a laboratory hydraulic press ensure process consistency? Achieve Reliable CR2032 Coin Cell Assembly

- How does a laboratory hydraulic press ensure the accuracy of test results? Master Precision Specimen Preparation

- Why use a laboratory hydraulic press for fertilizer and glass pellets? Achieve Precise Chemical Analysis Results

- What role does a laboratory hydraulic press play in the assembly of all-solid-state lithium-sulfur batteries?

- How is a laboratory hydraulic press utilized for nanoporous material precursors? Optimize Density & Uniformity

- What are the advantages of hydraulic press over mechanical press? Flexibility, Control & Cost Savings

- What are the limits of detection for XRF? Understanding Sensitivity for Accurate Analysis

- How does a laboratory hydraulic press facilitate catalyst preparation? Perfecting Pellets for Industrial Testing