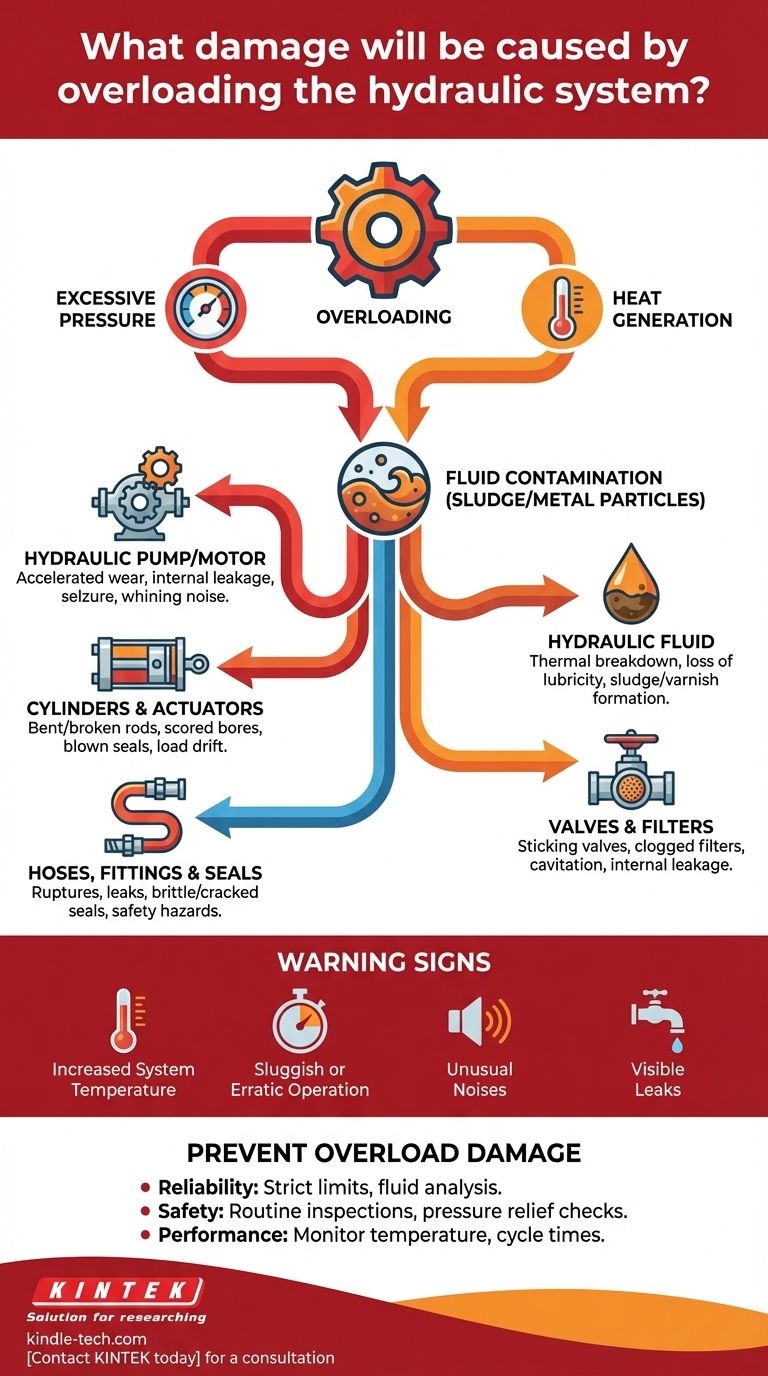

In short, overloading a hydraulic system triggers a destructive chain reaction, starting with extreme pressure and heat. This degrades the hydraulic fluid, destroys seals, accelerates wear on critical components like pumps and cylinders, and can ultimately lead to catastrophic hose ruptures or mechanical failures.

The core issue is that exceeding a system's design limits doesn't just strain one part; it creates a hostile operating environment of excessive pressure and heat that systematically attacks every component, turning the hydraulic fluid itself into a source of contamination and damage.

The Core Mechanisms of Overload Damage

To truly understand the consequences, you must first recognize the two primary forces at play when a system is overloaded: excessive pressure and runaway heat.

Excessive Pressure: The Primary Culprit

An overload condition demands more force than the system was designed to produce. This demand instantly spikes the fluid pressure.

While the pressure relief valve is designed to be the primary safety, it is often a symptom of the problem. If a system is consistently running in relief, it is operating in a state of constant, extreme stress.

This immense pressure physically stretches and stresses every component, from the pump housing to the cylinder walls and especially the hoses and fittings.

Heat Generation: The Silent Killer

High pressure directly generates heat. When hydraulic fluid is forced through the narrow passages of a relief valve or other orifices at extreme pressure, the resulting friction and turbulence rapidly increase the fluid's temperature.

This heat is the system's most insidious enemy. It causes thermal breakdown of the hydraulic fluid, destroying its lubricating properties and creating sludge and varnish.

Fluid Contamination: The Domino Effect

The combination of intense wear from high pressure and sludge from heat-damaged fluid creates a perfect storm of contamination.

Microscopic metal particles shear off from pumps and motors, circulating through the system. These particles, along with the newly formed sludge, act like liquid sandpaper, accelerating the destruction of every other component they touch.

A Component-by-Component Damage Analysis

Overloading doesn't discriminate. It systematically degrades every part of the hydraulic circuit.

Hydraulic Pumps and Motors

The pump is the heart of the system and often the first major component to suffer. High pressure causes accelerated wear on gears, vanes, or pistons, leading to internal leakage, reduced efficiency, and eventual seizure. A whining sound is a common auditory warning sign of a pump under extreme stress.

Cylinders and Actuators

Excessive pressure can cause cylinder rods to bend or even break. Internally, it can score the cylinder bore and blow out piston seals, causing the actuator to drift or fail to hold a load.

Hoses, Fittings, and Seals

These are often the first components to show visible failure. High-pressure spikes can cause hoses to rupture violently, creating a significant safety hazard from both the high-pressure fluid injection and the whipping hose. O-rings and seals, degraded by heat, become brittle and crack, leading to leaks.

Hydraulic Fluid

As noted, the fluid itself is a victim. Beyond losing its lubricity, the varnish created by heat can coat internal surfaces, causing valves to stick and reducing the system's ability to dissipate heat, which only makes the problem worse.

Valves and Filters

Valves subjected to high pressure and contaminated fluid can fail to shift, stick open, or leak internally. Filters become overwhelmed and clogged by the increased contaminants, which can lead to a condition of fluid starvation for the pump, causing cavitation and rapid destruction.

Common Pitfalls and Warning Signs

Ignoring the early signs of overload is the most common and costly mistake. Proactive monitoring is essential for preventing catastrophic failure.

Increased System Temperature

If the system reservoir or components are unusually hot to the touch, it is a primary indicator that the system is working too hard and generating excessive heat.

Sluggish or Erratic Operation

When a machine struggles to perform tasks it once did easily, it's a clear sign of internal leakage and wear. The system is losing pressure and efficiency.

Unusual Noises

A whining pump, knocking actuators, or a hissing sound from the relief valve are all audible cries for help. These noises indicate cavitation, mechanical stress, or a system constantly bypassing fluid under extreme pressure.

Visible Leaks

Even minor leaks are a significant warning sign. They indicate that seals have failed or fittings have been stressed beyond their limits, and they are often a precursor to a much larger failure.

How to Prevent Overload Damage

Preventing overload is far less expensive than reacting to its consequences. Your approach should be guided by your operational priorities.

- If your primary focus is reliability: Strictly adhere to the machine's designed operational limits and implement a regular fluid analysis program to detect thermal breakdown and contamination early.

- If your primary focus is safety: Conduct routine visual inspections of all hoses and fittings for signs of abrasion, cracking, or leaks, and verify that the system's pressure relief valves are set correctly.

- If your primary focus is performance: Monitor system temperature and cycle times closely; any degradation signals an underlying issue that needs immediate investigation to prevent cascading failure.

Ultimately, treating your hydraulic system with respect for its design limitations is the key to ensuring its long-term health, safety, and productivity.

Summary Table:

| Component | Primary Damage from Overload |

|---|---|

| Hydraulic Pump/Motor | Accelerated wear, internal leakage, seizure, whining noise |

| Cylinders & Actuators | Bent/broken rods, scored bores, blown seals, load drift |

| Hoses, Fittings & Seals | Ruptures, leaks, brittle/cracked seals, safety hazards |

| Hydraulic Fluid | Thermal breakdown, loss of lubricity, sludge/varnish formation |

| Valves & Filters | Sticking valves, clogged filters, cavitation, internal leakage |

Protect your equipment and avoid costly downtime. Overloading your hydraulic system leads to a destructive chain reaction of pressure, heat, and contamination that damages pumps, cylinders, and seals. For laboratories and industrial settings relying on hydraulic equipment, proactive maintenance and using the right components are key to reliability and safety.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right components and provide guidance to keep your systems running within safe operating limits.

Contact KINTEK today for a consultation to ensure your hydraulic systems operate safely and efficiently, protecting your investment and productivity.

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How many tons can a hydraulic press do? From 5-Ton Benchtop Units to 75,000-Ton Industrial Giants

- What is the most common cause of hydraulic system damage? Prevent Costly Failures with Proactive Maintenance

- How does a laboratory hydraulic press address ion transport challenges in LPSC batteries? Optimize Densification Now

- What is the primary function of a laboratory hydraulic press in TiO2 PLD target prep? Form High-Density Green Bodies

- What is the difference between rolling and bending? Choose the Right Metal Forming Process

- What role does a laboratory hydraulic press play in battery assembly? Ensure Superior Structural Integrity & Data.

- Can hydraulic systems that run too hot or too cold cause severe problems over time? Yes, and here's how to prevent it.

- What does the working principle of a hydraulic press depend on? Harness Pascal's Law for Immense Force