At its core, a furnace operator is a highly skilled industrial professional responsible for managing and controlling high-temperature furnaces used to melt, refine, or heat-treat materials like metal, glass, or ceramics. They are the critical link between raw materials and finished products, ensuring the entire process runs safely, efficiently, and to precise specifications.

A furnace operator does not simply watch a machine; they actively control a powerful and often dangerous industrial process. Their role is a demanding blend of technical oversight, hands-on labor, and unwavering vigilance to ensure both product quality and operational safety.

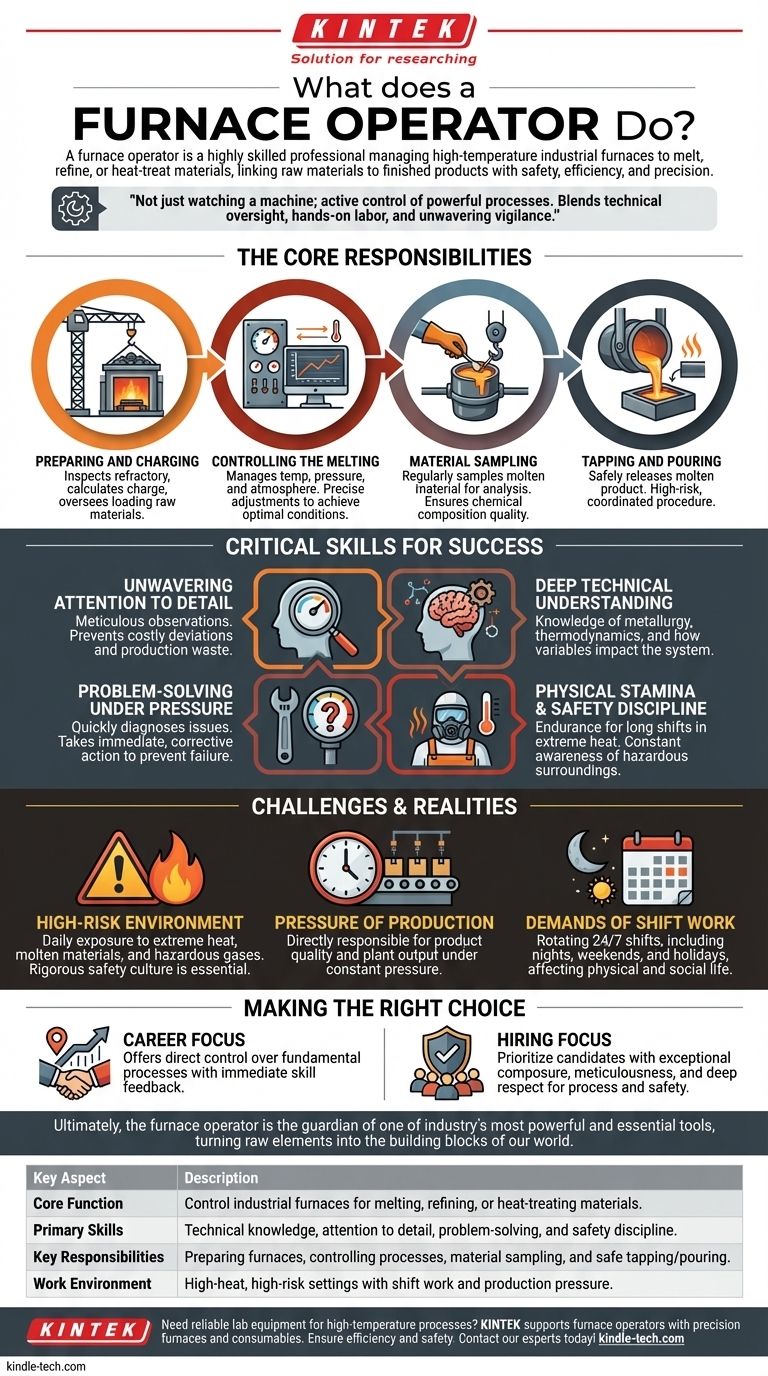

The Core Responsibilities of a Furnace Operator

The daily work of a furnace operator revolves around the meticulous control of the entire furnace cycle, from loading raw materials to extracting the finished product.

Preparing and Charging the Furnace

Before the process can begin, the operator prepares the furnace. This involves inspecting the furnace lining (refractory), ensuring all systems are operational, and calculating the correct mix of raw materials, known as the "charge." They then oversee the loading of these materials into the furnace using cranes or other heavy machinery.

Controlling the Melting Process

This is the heart of the operator's responsibility. They use a complex set of controls and computer systems to manage temperature, pressure, and the chemical atmosphere inside the furnace. They constantly monitor gauges and readouts, making precise adjustments to fuel, oxygen, or electrical current to achieve the perfect conditions for the material being processed.

Material Sampling and Analysis

Throughout the cycle, the operator takes small samples of the molten material for analysis. This ensures the chemical composition meets exact quality standards. Based on the results, they may add alloys or other elements to refine the final product.

Tapping and Pouring

Once the material is ready, the operator performs the "tapping" process—safely releasing the molten product from the furnace into a ladle or mold. This is a critical and high-risk procedure that requires immense focus and coordination with a team.

The Critical Skills of an Operator

Success in this role requires more than just following a checklist. It demands a specific combination of technical knowledge, mental fortitude, and physical capability.

Unwavering Attention to Detail

A small deviation in temperature or a miscalculation in material composition can ruin an entire batch, costing thousands of dollars and wasting hours of production. Operators must be meticulous in their observations and actions.

Deep Technical Understanding

Operators must understand the principles of metallurgy, thermodynamics, and chemistry. They need to know how different materials react to heat and how adjusting one variable—like airflow—will impact the entire system.

Problem-Solving Under Pressure

Furnaces are complex systems, and unexpected issues can arise. An effective operator can quickly diagnose a problem, such as an unusual temperature fluctuation or equipment malfunction, and take immediate, corrective action to prevent a larger failure.

Physical Stamina and Safety Discipline

The work environment is often extremely hot, noisy, and physically demanding. Operators must wear extensive personal protective equipment (PPE) and possess the physical endurance to work long shifts while remaining constantly aware of their hazardous surroundings.

Understanding the Challenges and Realities

The role of a furnace operator is critical to modern manufacturing, but it comes with significant challenges that must be understood.

A High-Risk Environment

Operators work daily with extreme heat, molten materials, heavy machinery, and potentially hazardous gases. A lapse in concentration or a failure to follow safety protocols can have severe consequences, making a rigorous safety culture absolutely essential.

The Pressure of Production

These operators are directly responsible for product quality and plant output. They work under constant pressure to meet production targets without compromising safety or the integrity of the multi-million dollar equipment they manage.

The Demands of Shift Work

Most foundries, mills, and manufacturing plants operate 24/7. This means furnace operators almost always work rotating shifts, including nights, weekends, and holidays, which can be physically and socially demanding.

Making the Right Choice

Understanding the furnace operator's role is key whether you are considering it as a career or hiring for the position.

- If your primary focus is a hands-on technical career: This role offers direct, tangible control over a fundamental industrial process with immediate feedback on your skill.

- If you are building a safety-first culture: The furnace operator is your most critical asset, as their expertise and discipline are the first line of defense against operational failure.

- If you are hiring for this role: Prioritize candidates who demonstrate exceptional composure, meticulousness, and a deep respect for process and safety, not just technical knowledge.

Ultimately, the furnace operator is the guardian of one of industry's most powerful and essential tools, turning raw elements into the building blocks of our world.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Control industrial furnaces for melting, refining, or heat-treating materials. |

| Primary Skills | Technical knowledge, attention to detail, problem-solving, and safety discipline. |

| Key Responsibilities | Preparing furnaces, controlling processes, material sampling, and safe tapping/pouring. |

| Work Environment | High-heat, high-risk settings with shift work and production pressure. |

Need reliable lab equipment for your high-temperature processes? KINTEK specializes in furnaces and lab consumables that support the precision and safety demands of furnace operators. Ensure your team has the right tools for efficient, safe material processing. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between an oven and a muffle furnace? A Guide to Selecting the Right Thermal Equipment

- What is a muffle furnace in the food industry? A Key Tool for Accurate Nutritional Analysis

- What is the importance of melting process? Master the Foundation of Metal Production

- What is the heating mechanism of a muffle furnace? Unlock Precise, Contamination-Free Heating

- What is a muffle oven used for? Achieve High-Purity Heat Treatment and Analysis