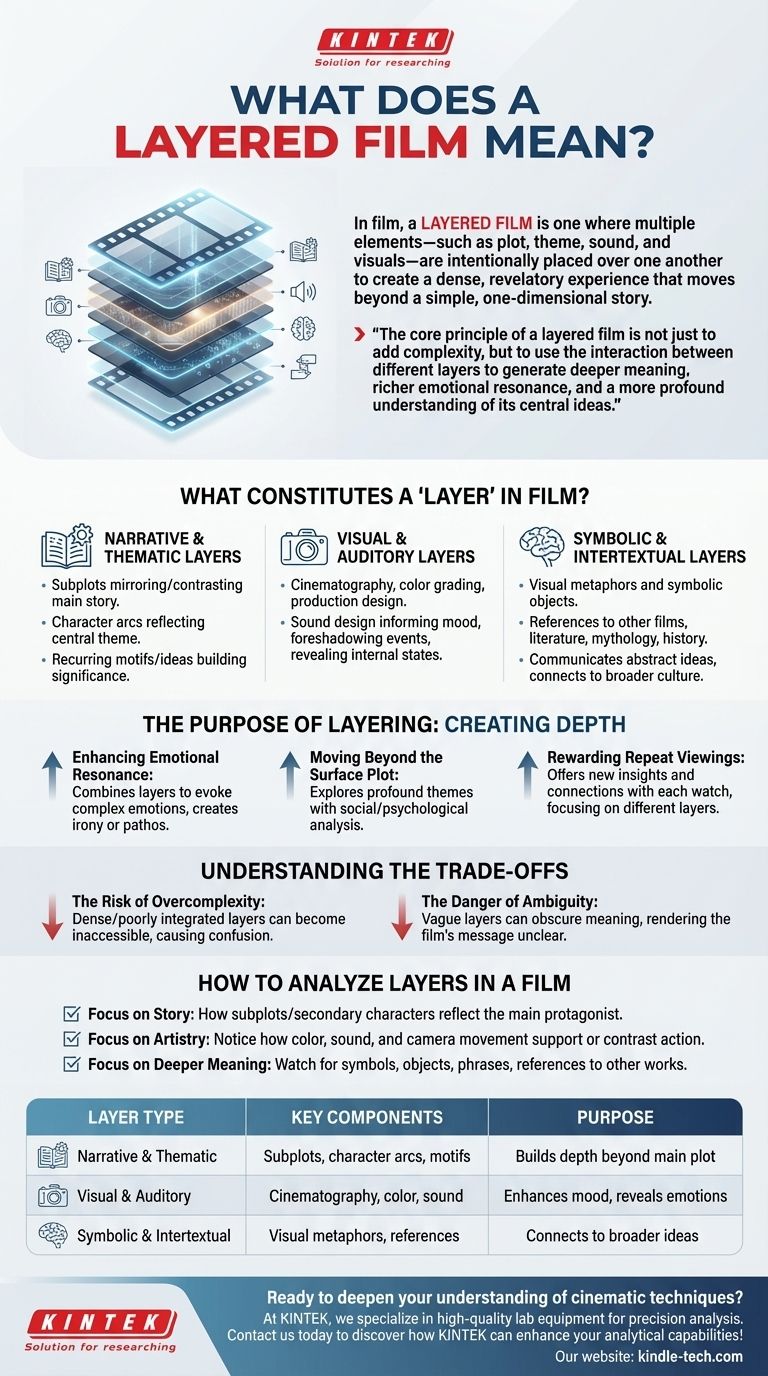

In film, a layered film is one where multiple elements—such as plot, theme, sound, and visuals—are intentionally placed over one another. This technique allows the audience to experience these elements both individually and as a combined whole. The goal is to create a dense, revelatory experience that moves beyond a simple, one-dimensional story.

The core principle of a layered film is not just to add complexity, but to use the interaction between different layers to generate deeper meaning, richer emotional resonance, and a more profound understanding of its central ideas.

What Constitutes a "Layer" in Film?

To understand a layered film, you must first be able to identify the individual layers. These are not random details but deliberate artistic choices that work in concert.

Narrative and Thematic Layers

The most apparent layers exist within the story itself. A film might present a straightforward plot on the surface, but underneath, other narrative and thematic currents are running.

This includes subplots that mirror or contrast with the main story, character arcs that reflect the film's central theme, and recurring motifs or ideas that build in significance over time.

Visual and Auditory Layers

Cinema is a sensory medium, and its technical elements provide powerful layers. The way a film looks and sounds can add meaning that dialogue alone cannot convey.

Cinematography, color grading, production design, and sound design are not just background elements. They are active layers that can inform the mood, foreshadow events, or reveal a character's internal state. For example, a jarring, dissonant score layered over a visually calm scene creates a sense of unease and hidden tension.

Symbolic and Intertextual Layers

The deepest layers often involve symbolism and references outside the film itself. This is where a film communicates abstract ideas and connects to a broader cultural conversation.

This can include visual metaphors, objects that carry symbolic weight, or intertextual references to other films, literature, mythology, or historical events. These layers reward an attentive viewer with a richer understanding of the filmmaker's intent.

The Purpose of Layering: Creating Depth

Filmmakers use layering to elevate a story from a simple sequence of events into a complex and meaningful work of art.

Enhancing Emotional Resonance

By combining layers, a filmmaker can evoke complex emotions. The contrast between what a character says and what the music or camera angle conveys can create powerful irony or pathos.

Moving Beyond the Surface Plot

Layering is the primary tool for exploring profound themes. A crime story is not just about the crime; layers of social commentary or psychological analysis give the plot its true weight and significance.

Rewarding Repeat Viewings

A well-layered film is rarely exhausted in a single watch. Each viewing allows the audience to focus on a different layer—the sound design, a recurring visual motif, a character's subtle expressions—revealing new connections and insights.

Understanding the Trade-offs

While powerful, the technique of layering is not without its challenges. The line between complexity and confusion can be thin.

The Risk of Overcomplexity

If layers are too dense or poorly integrated, a film can become inaccessible or feel pretentious. The audience may struggle to find a coherent thread, leading to frustration rather than revelation.

The Danger of Ambiguity

Layers should ideally enrich the film's meaning, not obscure it entirely. When symbolic or thematic layers are too vague, they can render the film's message unclear, leaving the audience to wonder what, if anything, was the point.

How to Analyze Layers in a Film

Recognizing and interpreting layers transforms you from a passive viewer into an active participant. Your approach can change depending on your goal.

- If your primary focus is the story: Pay attention to how subplots and secondary characters reflect, challenge, or illuminate the journey of the main protagonist.

- If your primary focus is the artistry: Actively notice how the color palette, sound design, and camera movement support or deliberately contrast with the on-screen action and dialogue.

- If your primary focus is uncovering deeper meaning: Watch for recurring symbols, objects, or phrases, and consider any potential references to other works of art, history, or philosophy.

Understanding how to see these distinct elements and how they converge is the key to appreciating the full depth of the cinematic experience.

Summary Table:

| Layer Type | Key Components | Purpose |

|---|---|---|

| Narrative & Thematic | Subplots, character arcs, recurring motifs | Builds depth and thematic resonance beyond the main plot |

| Visual & Auditory | Cinematography, color grading, sound design | Enhances mood, foreshadows events, reveals character emotions |

| Symbolic & Intertextual | Visual metaphors, references to art/history | Connects the film to broader cultural and philosophical ideas |

Ready to deepen your understanding of cinematic techniques? At KINTEK, we specialize in providing high-quality lab equipment and consumables that help researchers and filmmakers analyze visual and auditory layers with precision. Whether you're studying film composition or advancing laboratory projects, our tools support your pursuit of clarity and depth. Contact us today to discover how KINTEK can enhance your analytical capabilities!

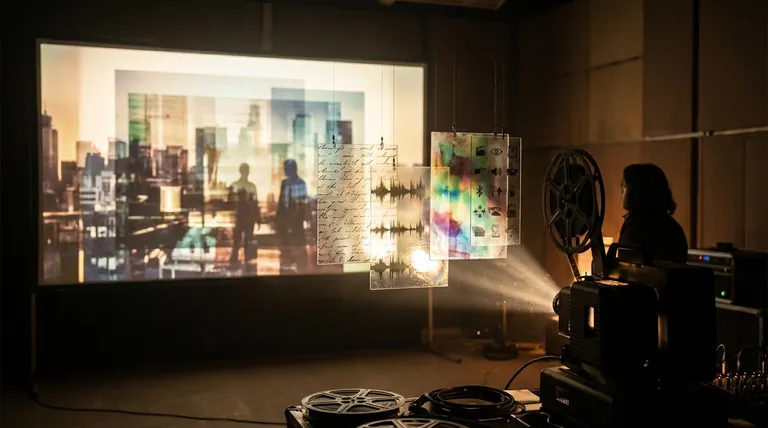

Visual Guide

Related Products

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- High Temperature Resistant Optical Quartz Glass Sheet

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What are five applications of soldering? From Electronics to Art, Master Material Joining

- What are the components of sintering? Master the 4-Step Process for Stronger Materials

- What material cannot be heat-treated? Understanding the Limits of Hardening and Phase Transformation

- What is the meaning of vacuum pyrolysis? Maximize Liquid Fuel Yield from Waste

- What are the process advantages of combining high-speed shear systems with chemical catalysts? Maximize Biomass Yield

- What is the unit of measurement for coating thickness? Microns (μm) and Nanometers (nm) Explained

- In which three ways can we use biomass as a source of energy? Harnessing Organic Matter for Power

- What is DC magnetron sputtering? A High-Speed Method for Thin-Film Deposition