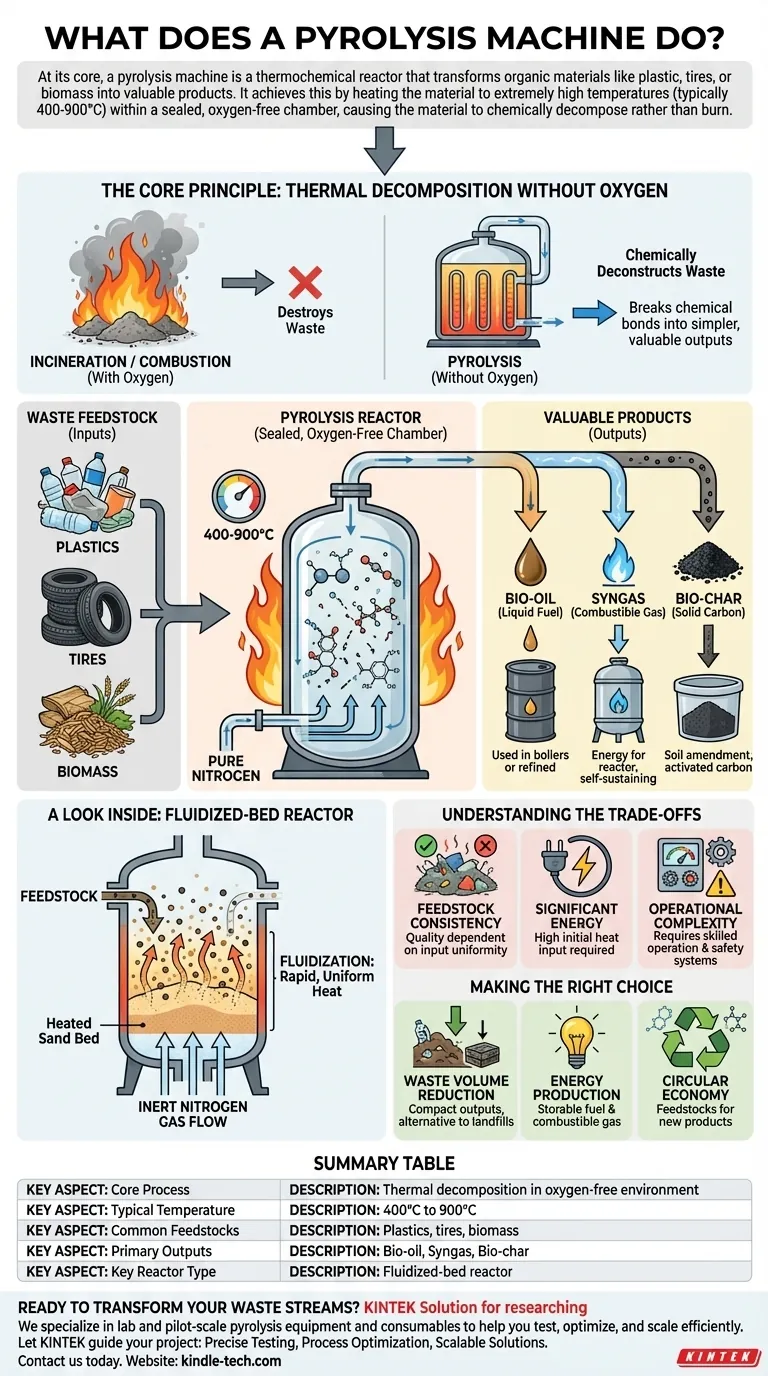

At its core, a pyrolysis machine is a thermochemical reactor that transforms organic materials like plastic, tires, or biomass into valuable products. It achieves this by heating the material to extremely high temperatures (typically 400-900°C) within a sealed, oxygen-free chamber, causing the material to chemically decompose rather than burn.

The central purpose of pyrolysis is not to destroy waste but to chemically deconstruct it. By eliminating oxygen from the heating process, the machine breaks down complex organic polymers into simpler, more valuable outputs: a liquid fuel (bio-oil), a combustible gas (syngas), and a solid carbon residue (bio-char).

The Core Principle: Thermal Decomposition Without Oxygen

Pyrolysis is a fundamentally different process from incineration or combustion. Understanding this distinction is key to grasping its value.

What "Pyrolysis" Actually Means

The term comes from the Greek words 'pyro' (fire) and 'lysis' (to separate). A pyrolysis machine uses intense heat to literally break apart the chemical bonds within a material.

Because this happens in the absence of oxygen, the material doesn't combust. Instead of producing smoke and ash, it reverts to a mixture of simpler, stable components.

The Critical Role of an Inert Atmosphere

The defining feature of a pyrolysis reactor is its oxygen-starved environment. This is often achieved by purging the chamber with an inert gas like pure nitrogen.

This inert atmosphere is non-negotiable. It prevents unwanted chemical reactions—specifically, burning—and ensures the feedstock decomposes into the desired outputs of oil, gas, and char.

From Waste Feedstock to Valuable Products

A pyrolysis plant is essentially an advanced recycling system, capable of processing difficult materials and converting them into a trio of useful resources.

The Inputs: What Can Be Processed?

The technology is versatile, designed to handle a range of organic polymeric wastes. Common feedstocks include:

- End-of-life plastics

- Scrap tires

- Biomass (wood chips, agricultural waste)

The Outputs: A Trio of Resources

The decomposition process consistently yields three primary products:

- Bio-oil (Pyrolysis Oil): A liquid fuel that can be used in some boilers or further refined into higher-grade fuels and chemical feedstocks.

- Syngas (Synthesis Gas): A mixture of combustible gases. A portion of this gas is often captured and used to provide the energy needed to heat the reactor, making the process more self-sustaining.

- Bio-char: A stable, solid material rich in carbon. It can be used as a soil amendment to improve fertility or processed further to create high-value products like activated carbon for filtration.

A Look Inside a Common Reactor Type

To make the process efficient, specialized reactors are used. One of the most effective designs is the fluidized-bed reactor.

The Function of the Sand Bed

This type of reactor contains a layer of bed material, such as sand. The sand is heated and acts as the primary heat transfer medium.

When feedstock is introduced, it is mixed with the hot sand, which ensures rapid and uniform heat distribution throughout the material for efficient decomposition.

How "Fluidization" Works

The inert nitrogen gas is pumped in from the bottom of the reactor. This gas flow is strong enough to lift and suspend the sand and feedstock particles, causing them to behave like a fluid.

This "fluidization" maximizes the surface area of the material exposed to heat, dramatically increasing the efficiency of the reaction and boosting the yield of bio-oil and syngas.

Understanding the Trade-offs

While powerful, pyrolysis technology is not a universal solution and comes with operational realities that must be considered.

Feedstock Consistency is Key

The efficiency and output quality of a pyrolysis machine are highly dependent on the input material. Contaminants or inconsistent moisture levels in the feedstock can disrupt the process and affect the final products.

Significant Energy Requirements

Heating a reactor to over 400°C is an energy-intensive process. While the syngas produced can be used to offset this demand, a significant initial energy input is required to start and stabilize the system.

Operational Complexity

These are not simple machines. They require sophisticated control and safety systems to manage high temperatures, pressures, and the production of flammable gases and liquids, demanding skilled operators and rigorous maintenance protocols.

Making the Right Choice for Your Goal

Pyrolysis serves distinct goals within waste management and resource recovery. Your objective determines its value.

- If your primary focus is waste volume reduction: Pyrolysis is an excellent alternative to landfills, converting the bulk of organic waste into more compact and often valuable outputs.

- If your primary focus is energy production: The technology directly transforms a waste liability into localized energy sources in the form of storable bio-oil and combustible syngas.

- If your primary focus is a circular economy: Pyrolysis excels at breaking down materials like plastics and tires into their fundamental chemical components, creating feedstocks for new products.

Ultimately, a pyrolysis machine provides a sophisticated method for unlocking the chemical value stored within organic waste, turning a disposal problem into a resource opportunity.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Process | Thermal decomposition of organic materials in an oxygen-free environment. |

| Typical Temperature | 400°C to 900°C |

| Common Feedstocks | Plastics, tires, biomass (wood, agricultural waste). |

| Primary Outputs | Bio-oil (liquid fuel), Syngas (combustible gas), Bio-char (solid carbon). |

| Key Reactor Type | Fluidized-bed reactor for efficient, uniform heating. |

Ready to transform your waste streams into valuable resources?

A pyrolysis machine from KINTEK can be the cornerstone of your waste-to-energy or advanced recycling operation. We specialize in supplying robust lab and pilot-scale pyrolysis equipment and consumables, helping you test, optimize, and scale your processes efficiently.

Let KINTEK's expertise guide your project:

- Precise Testing: Validate your specific feedstock with reliable lab equipment.

- Process Optimization: Achieve maximum yields of bio-oil, syngas, and bio-char.

- Scalable Solutions: From R&D to pilot plants, we provide the equipment you need to succeed.

Contact us today to discuss how our pyrolysis solutions can turn your waste management challenge into a profitable opportunity.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Powerful Plastic Crusher Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas