In essence, a temperature control is a process that automatically maintains a desired temperature. It works by first measuring the current temperature of a space or substance. It then compares this measurement to a pre-set target and adjusts the flow of heat energy—either adding or removing it—to bring the system back to the target temperature.

The fundamental purpose of temperature control is not just to heat or cool, but to create stability. It achieves this through a continuous feedback loop: measure, compare, and adjust, ensuring a system operates at a predictable and consistent temperature.

The Three Core Functions of Temperature Control

A temperature control system, whether in a home thermostat or an industrial furnace, operates on a simple yet powerful three-step cycle. This process happens continuously to maintain a stable environment.

1. Measuring the Current State

The process begins with a sensor. The sensor's only job is to accurately measure the current temperature of the system.

Different sensors are used for different temperature ranges. For example, a thermocouple is common for temperatures below 1700°C, while an infrared instrument might be used for higher temperatures.

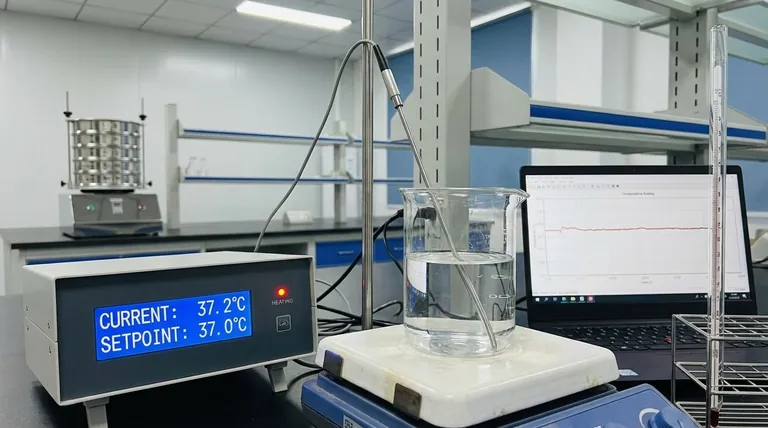

2. Comparing to the Desired State

The controller takes the measurement from the sensor and compares it to a setpoint. The setpoint is the target temperature that has been programmed into the system.

This setpoint can be fixed or adjusted by a user, for instance, by turning a dial or using a digital interface. This act of comparison determines if the system is too hot, too cold, or just right.

3. Adjusting the System

Based on the comparison, the controller takes action. This is the "control" part of the process.

If the measured temperature is below the setpoint, the controller activates a heating element. Once the temperature rises to meet the setpoint, the controller deactivates it. Conversely, if the temperature drops again, the heating process is re-initiated to maintain the target.

Understanding the Trade-offs and Limitations

While the concept is straightforward, achieving precise temperature control involves navigating a few key challenges. Understanding these limitations is crucial for any real-world application.

Overshoot and Undershoot

Simple on/off controllers often cause the temperature to go slightly above the setpoint (overshoot) or fall below it (undershoot). This is due to thermal lag; a heating element remains hot for a short time even after it's turned off, continuing to heat the system.

Sensor Placement is Critical

The accuracy of the entire system depends on where the sensor is located. A sensor placed too close to a heating source will give a falsely high reading, while one placed too far away might not detect changes quickly enough.

System Responsiveness

The size and nature of the system being controlled affect performance. A large industrial oven cannot change temperature as quickly as a small hot plate, which impacts how tightly the controller can maintain the setpoint.

Making the Right Choice for Your Goal

Ultimately, the goal of a temperature control system is to produce a reliable and predictable outcome. How you apply this depends entirely on your primary objective.

- If your primary focus is process stability (e.g., manufacturing, lab experiments): The key is using a responsive control loop that minimizes temperature fluctuations around your critical setpoint.

- If your primary focus is energy efficiency (e.g., HVAC systems): Your goal is to use a controller that avoids frequent on/off cycles and minimizes overshoot, which prevents wasting heating or cooling energy.

- If your primary focus is safety (e.g., preventing overheating): The control system acts as a crucial automatic safeguard, ensuring that heat sources are cut off before a dangerous threshold is ever reached.

By understanding these core principles, you can ensure your system delivers not just heat, but consistent and dependable results.

Summary Table:

| Core Function | Key Component | Purpose |

|---|---|---|

| Measure | Sensor (e.g., Thermocouple) | Accurately reads the current temperature. |

| Compare | Controller | Compares the measured temperature to the target setpoint. |

| Adjust | Heating/Cooling Element | Adds or removes heat to maintain the desired temperature. |

Need precise temperature control for your lab processes? KINTEK specializes in high-performance lab equipment with advanced temperature control systems. Whether your priority is process stability for experiments, energy efficiency, or critical safety protocols, our solutions deliver the reliability you need. Contact our experts today to find the perfect system for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide