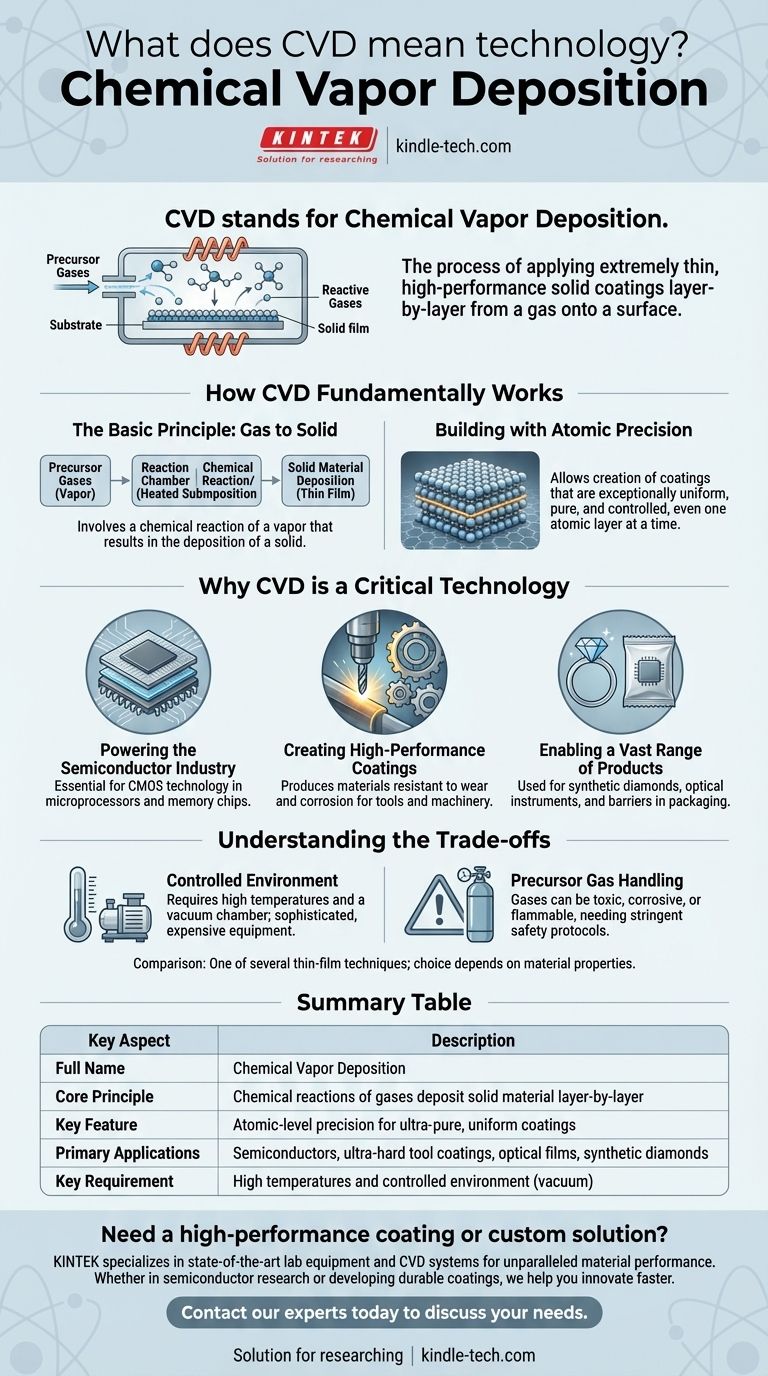

CVD stands for Chemical Vapor Deposition. It is a highly versatile manufacturing process used to apply extremely thin, high-performance solid coatings onto a surface. The technique works by introducing reactive gases into a chamber, which then deposit a solid material, layer by layer, onto a target object.

At its core, Chemical Vapor Deposition is a foundational technology for building advanced materials from the atom up. It's the process that enables the creation of everything from the complex layers in a computer chip to the ultra-hard coating on a drill bit.

How CVD Fundamentally Works

The name "Chemical Vapor Deposition" perfectly describes the process. It involves a chemical reaction of a vapor (gas) that results in the deposition of a solid.

The Basic Principle: Gas to Solid

The process begins by placing an object, known as a substrate, inside a reaction chamber. One or more volatile precursor gases are then introduced into this chamber.

When these gases come into contact with the heated substrate, they react or decompose, leaving behind a thin film of solid material. This deposited layer is the desired coating.

Building with Atomic Precision

The power of CVD lies in its precision. The process allows for the creation of coatings that are exceptionally uniform, pure, and controlled, sometimes just one atomic layer at a time.

This level of control is what makes CVD indispensable for manufacturing microscopic components where even the slightest imperfection can cause a failure.

Why CVD is a Critical Technology

CVD is not a niche process; it is a cornerstone of modern manufacturing across nearly every industry, enabling the creation of small, powerful, and durable products.

Powering the Semiconductor Industry

The entire digital world is built on semiconductors. CVD is essential for manufacturing the Complementary Metal-Oxide-Semiconductor (CMOS) technology used in integrated circuits, microprocessors, and memory chips. The incredibly complex and tiny layers within these components are built using CVD.

Creating High-Performance Coatings

CVD is used to produce materials that are exceptionally hard and resistant to wear and corrosion. This is vital for industrial applications like coating machine tools, bearings, and other parts that must withstand extreme conditions.

Enabling a Vast Range of Products

The applications of CVD are incredibly diverse. It is used to create synthetic diamonds for both industrial and jewelry purposes and to apply the thin aluminum barrier inside potato chip bags. It is also used to fabricate dielectrics, optical instruments, and even pigments like carbon black.

Understanding the Trade-offs

While powerful, CVD is a complex process with specific requirements that make it unsuitable for every application.

The Need for a Controlled Environment

CVD typically requires high temperatures and a vacuum chamber to work effectively. The equipment is sophisticated and requires precise control over temperature, pressure, and gas flow, which can make the process expensive.

Precursor Gas Handling

The precursor gases used as the building blocks for the coatings can often be toxic, corrosive, or flammable. This necessitates stringent safety protocols and specialized handling equipment, adding to the operational complexity.

Comparison to Other Methods

CVD is just one of several thin-film deposition techniques. For some materials or applications, other methods like Physical Vapor Deposition (PVD) may be more suitable or cost-effective. The choice depends entirely on the desired material properties and the substrate being coated.

How to Apply This to Your Field

Understanding CVD allows you to recognize its impact on different sectors and appreciate the precision engineering behind many modern products.

- If your primary focus is electronics and computing: See CVD as the fundamental process enabling the creation of the microprocessors and memory that power our digital world.

- If your primary focus is material science and engineering: View CVD as a powerful tool for designing ultra-pure, durable coatings that enhance the properties of base materials.

- If your primary focus is on consumer goods: Recognize CVD as a hidden technology responsible for features like the protective, scratch-resistant coatings on optics or the freshness barriers in food packaging.

Ultimately, Chemical Vapor Deposition is the art of building advanced materials from the gas phase up, making it an invisible yet indispensable pillar of modern technology.

Summary Table:

| Key Aspect | Description |

|---|---|

| Full Name | Chemical Vapor Deposition |

| Core Principle | Uses chemical reactions of gases to deposit solid material layer-by-layer onto a substrate. |

| Key Feature | Enables atomic-level precision for ultra-pure, uniform coatings. |

| Primary Applications | Semiconductor manufacturing, ultra-hard tool coatings, optical films, synthetic diamonds. |

| Key Requirement | High temperatures and a controlled environment (often a vacuum chamber). |

Need a high-performance coating or a custom thin-film solution for your lab or production line?

The precise control and material versatility of CVD technology are what make advanced manufacturing possible. At KINTEK, we specialize in providing state-of-the-art lab equipment and consumables, including CVD systems, to help you achieve unparalleled material performance. Whether you're in semiconductor research, developing new durable coatings, or exploring advanced materials, our expertise can help you innovate faster.

Contact our experts today to discuss how our CVD solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is vapour growth technique in crystal growth? Achieve Unmatched Purity and Precision

- What is the sputtering process of magnetron deposition? A Guide to Efficient Thin-Film Coating

- What are the application of thin films in optics? Control Light with Nanometer Precision

- What is the difference between ion beam sputtering and magnetron sputtering? Choosing the Right PVD Technique

- Can CVD deposit metal? A Guide to High-Purity, Conformal Metal Films

- How is pyrolysis oil produced? Turn Biomass into Bio-Crude with Fast Pyrolysis

- What is the difference between chemical and physical vapour deposition? Choose the Right Thin-Film Coating Method

- Why is high-speed wafer rotation necessary for vertical CVD? Master Flow Engineering for 4H-SiC Thin Films