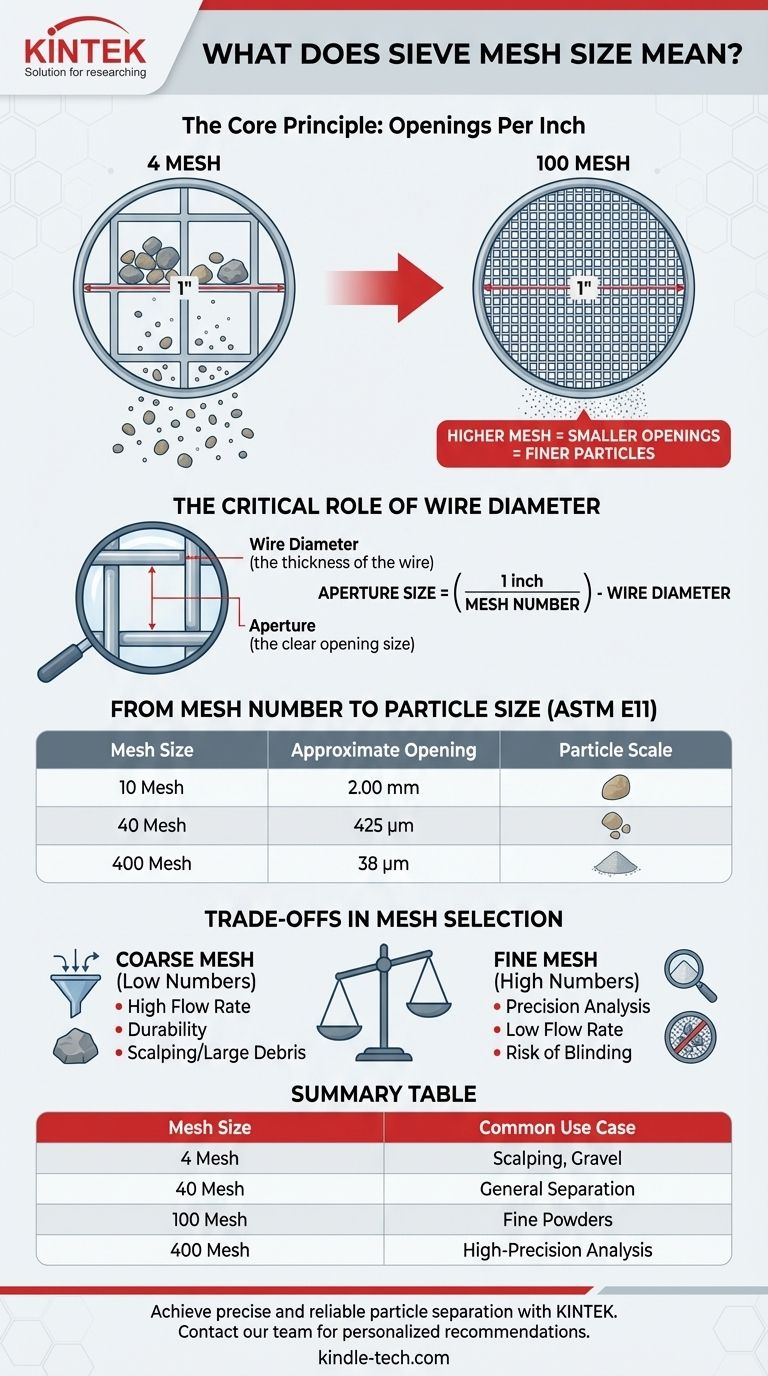

In the simplest terms, a sieve's mesh size refers to the number of openings across one linear inch of its screen. This means a sieve with a higher mesh number has more openings per inch, which in turn means the individual holes are smaller and can separate finer particles.

The central concept to grasp is the inverse relationship: as the mesh number increases, the size of the particles that can pass through the screen decreases. This single principle is the key to selecting the correct sieve for any application.

How Sieve Mesh is Defined

Understanding the number on the side of a sieve is crucial for achieving repeatable and accurate results in particle separation. The number is not an arbitrary grade but a specific physical measurement.

The Core Principle: Openings Per Inch

The mesh number is a direct count of the openings in the wire cloth along a straight, one-inch line. For example, a 4-mesh screen has four openings per linear inch, while a 100-mesh screen has one hundred openings per linear inch.

This measurement provides a standardized way to quickly identify the general fineness of a sieve.

The Critical Role of Wire Diameter

A common misconception is that a 100-mesh screen has openings that are exactly 1/100th of an inch wide. This is incorrect because the calculation must also account for the thickness of the wire used to weave the mesh.

The actual size of the opening (aperture) is determined by subtracting the wire diameter from the space between the centers of the wires. This is why standardized specifications are so important.

From Mesh Number to Particle Size

To ensure global consistency, standards like ASTM E11 (in the U.S.) and ISO 3310-1 define the precise relationship between a mesh number, the required wire diameter, and the resulting nominal opening size. This allows you to directly correlate a mesh number with a specific particle size in millimeters (mm) or micrometers (microns).

For example, according to the ASTM E11 standard:

- A 10 Mesh sieve has an opening of 2.00 mm (2000 µm).

- A 40 Mesh sieve has an opening of 425 µm (0.425 mm).

- A 400 Mesh sieve has an opening of 38 µm (0.038 mm).

Understanding the Trade-offs in Mesh Selection

Choosing a mesh size is not just about the particle size you want to separate; it's a balance between precision, speed, and durability.

Fine Mesh (High Numbers)

Sieves with high mesh numbers (e.g., 200 mesh and above) are designed for precision. They can separate very fine powders and are essential for quality control in industries like pharmaceuticals and pigments.

The downside is a significantly reduced flow rate. They are also more susceptible to damage and a phenomenon called blinding.

Coarse Mesh (Low Numbers)

Coarse sieves (e.g., 4 to 20 mesh) are robust and allow for very high throughput. They are ideal for "scalping"—removing large contaminants from a bulk material—or for sorting large aggregates like gravel and sand.

Their obvious limitation is a lack of precision. They cannot be used to analyze or separate fine particles.

The Problem of Blinding and Clogging

Blinding occurs when particles that are very close in size to the mesh openings become wedged in the apertures, blocking the screen. This dramatically reduces the sieve's efficiency and is a common challenge when working with fine meshes and materials with a narrow particle size distribution.

Selecting the Right Mesh for Your Application

Your final choice depends entirely on the goal of your separation process. Consider what you are trying to achieve to determine the correct specification.

- If your primary focus is scalping or removing large debris: Use a coarse, low-number mesh (e.g., 4 to 30 mesh) for durability and maximum throughput.

- If your primary focus is precise particle size analysis: Use a certified stack of sieves with a graduated range of mesh sizes (e.g., 35, 60, 120, 200 mesh) to determine the particle distribution curve of a sample.

- If your primary focus is filtering a liquid to a specific purity: Match the mesh opening in microns to the smallest particle you need to remove, as this is more precise than relying on the mesh number alone.

Ultimately, understanding mesh size empowers you to select the exact tool required to achieve a reliable and efficient separation.

Summary Table:

| Mesh Size | Approximate Opening (ASTM E11) | Common Use Case |

|---|---|---|

| 4 Mesh | 4.75 mm | Scalping, Gravel |

| 40 Mesh | 425 µm | General Separation |

| 100 Mesh | 150 µm | Fine Powders |

| 400 Mesh | 38 µm | High-Precision Analysis |

Achieve precise and reliable particle separation with the right sieve. The experts at KINTEK understand that selecting the correct mesh size is critical for your lab's accuracy and efficiency. Whether you need a single sieve for a specific task or a full certified stack for detailed particle analysis, we provide high-quality lab equipment tailored to your needs. Contact our team today to discuss your application and get a personalized recommendation.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency