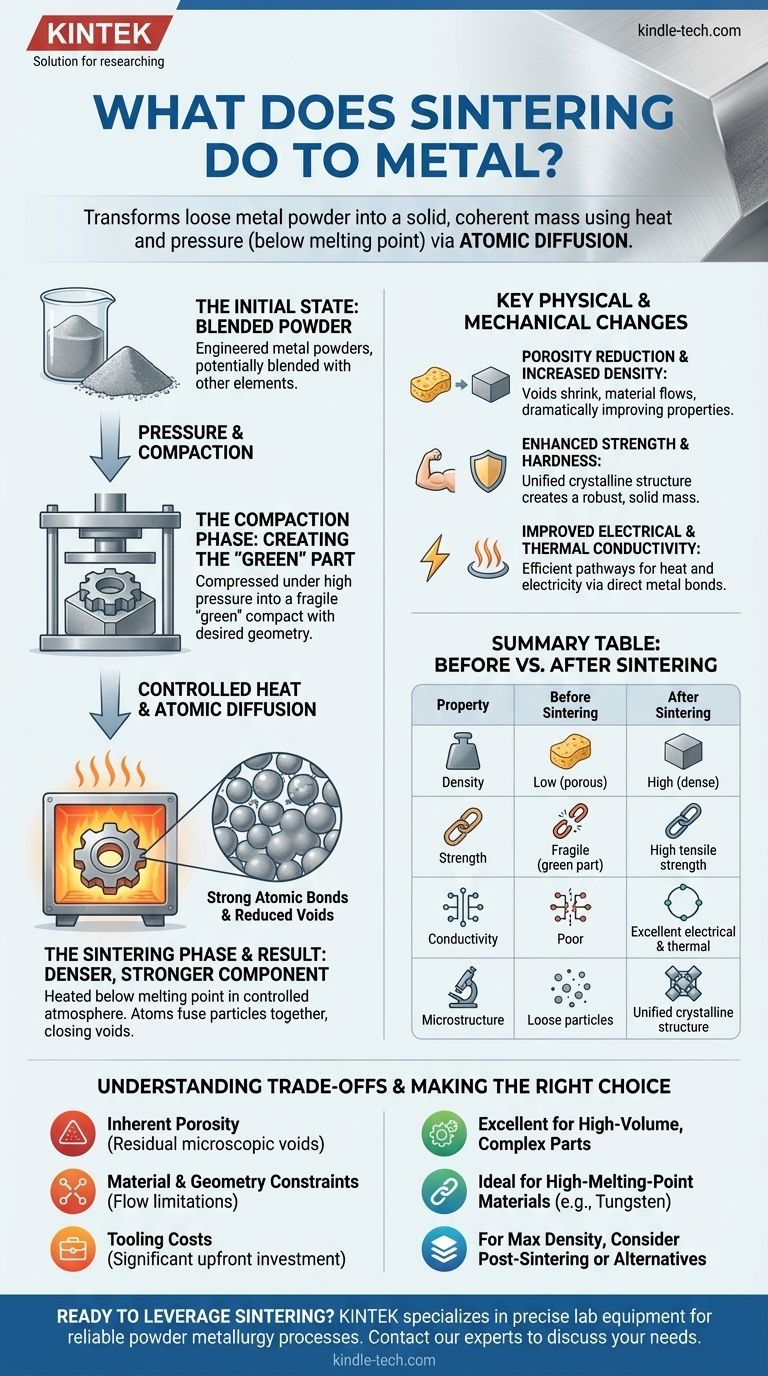

In short, sintering transforms loose metal powder into a solid, coherent mass using heat and pressure. Unlike melting, the metal is heated to a temperature below its melting point, causing the individual powder particles to bond together on an atomic level. This process dramatically increases the material's density, strength, and overall integrity.

Sintering is fundamentally a process of atomic diffusion. It uses controlled heat to fuse metal powder particles into a solid component, achieving density and strength without having to fully melt the base material.

How Sintering Fundamentally Transforms Metal Powder

The sintering process, also known as powder metallurgy, is a multi-stage transformation from a loose collection of particles into a functional, solid part.

The Initial State: Blended Powder

The process begins with fine, engineered metal powders. These may be blended with other elements, such as copper powder or cemented carbides, to achieve specific final properties in the alloy.

The Compaction Phase: Creating the "Green" Part

Next, the powder blend is poured into a die and compressed under high pressure. This step forms the material into its desired shape, creating what is known as a "green" compact. This part has the correct geometry but is still mechanically fragile.

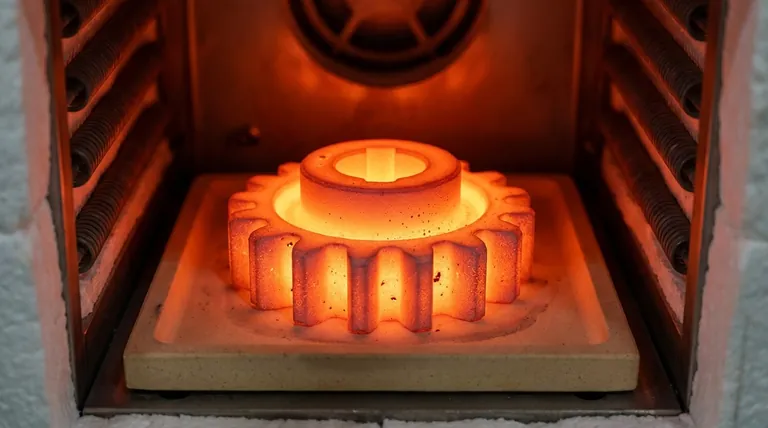

The Sintering Phase: Atomic Bonding Without Melting

The green part is then heated in a controlled-atmosphere furnace. The temperature is high enough to energize the metal atoms but remains below the material's melting point. This heat drives a process called atomic diffusion, where atoms migrate across the boundaries of the particles, causing them to fuse together and form strong metallic bonds.

The Result: A Denser, Stronger Component

As the particles bond, the voids and pores between them shrink or close up entirely. The material flows into these voids, causing the entire component to increase in density and often decrease slightly in overall volume, resulting in a strong, solid part.

Key Physical and Mechanical Changes

Sintering imparts several critical property changes to the metal, moving it from a fragile compact to a robust component.

Porosity Reduction and Increased Density

The most significant change is the reduction of empty space between particles. As the material's density increases, its mechanical and physical properties improve dramatically.

Enhanced Strength and Hardness

The formation of a new, unified crystalline structure across particle boundaries creates a strong, solid mass. This directly translates to significantly higher tensile strength and hardness compared to the pre-sintered green part.

Improved Electrical and Thermal Conductivity

With the elimination of pores and the creation of direct metal-to-metal bonds, pathways for heat and electricity become far more efficient. This results in much better thermal and electrical conductivity in the final part.

Understanding the Trade-offs

While powerful, sintering is a specific process with inherent characteristics that make it suitable for some applications and less so for others.

Inherent Porosity

Even in a well-controlled process, achieving 100% density can be difficult. Some residual microscopic porosity may remain, which can be a limiting factor for applications requiring the absolute highest fatigue strength or hermetic sealing.

Material and Geometry Constraints

The need to compact powder in a die means that certain complex internal geometries can be challenging or impossible to produce directly. The flow characteristics of the metal powder also play a significant role in what shapes can be effectively compacted.

Tooling Costs

The dies and tooling required for the compaction step are robust and precisely machined, representing a significant upfront investment. This makes sintering most cost-effective for medium-to-high volume production runs where the tooling cost can be amortized over many parts.

Making the Right Choice for Your Application

Understanding the fundamental transformation of sintering allows you to apply it effectively.

- If your primary focus is cost-effectively producing complex, near-net-shape parts in high volumes: Sintering is an excellent choice due to its low material waste and high repeatability.

- If your primary focus is working with high-melting-point materials like tungsten, molybdenum, or carbides: Sintering is often the only practical manufacturing method, as melting these materials is energy-prohibitive.

- If your primary focus is achieving the absolute maximum material density and fatigue strength: You may need to consider post-sintering operations (like hot isostatic pressing) or alternative methods like forging for the most demanding applications.

Ultimately, sintering empowers you to create strong, functional metal parts from powder by building them up at an atomic level.

Summary Table:

| Property | Before Sintering | After Sintering |

|---|---|---|

| Density | Low (porous) | High (dense) |

| Strength | Fragile (green part) | High tensile strength |

| Conductivity | Poor | Excellent electrical & thermal |

| Microstructure | Loose particles | Unified crystalline structure |

Ready to leverage sintering for your high-volume or complex metal parts? KINTEK specializes in providing the precise lab equipment and consumables needed for reliable powder metallurgy processes. Our expertise ensures you achieve the density, strength, and performance your applications demand. Contact our experts today to discuss how we can support your laboratory's sintering success.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- How does an industrial vacuum drying oven contribute to the post-processing of gradient cathode material precursors?

- How does a high-temperature furnace with oxygen flow control ensure the quality of SiO2 layers? Achieve Precision Growth

- What role does a high-precision tempering furnace play in 42CrMo4 steel treatment? Optimize Strength and Toughness

- What does bond strength depend on in braze welding? Master the 3 Keys to a Strong Joint

- How does a high-temperature furnace contribute to the PWHT of 2.25Cr-1Mo steel? Ensure Weld Integrity and Stability

- What is the process of calcination in a furnace? A Guide to Controlled Thermal Transformation

- How do vacuum furnaces heat? Achieve Purity and Precision in High-Temperature Processing

- What is vacuum retorting? A Guide to High-Purity Material Processing