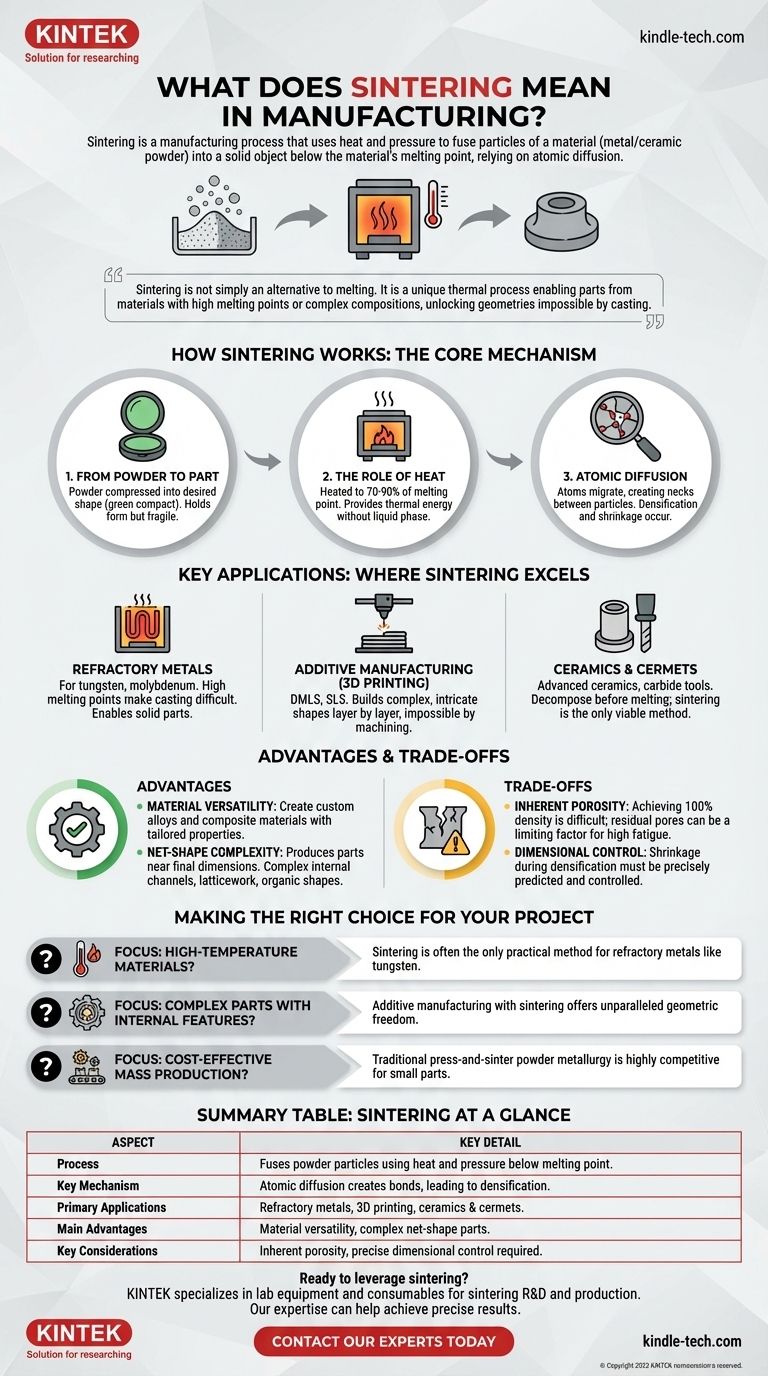

In essence, sintering is a manufacturing process that uses heat and pressure to fuse particles of a material, like a metal or ceramic powder, into a solid object. Critically, this occurs at a temperature below the material's melting point, relying on atomic diffusion to bond the particles together, rather than turning the bulk material into a liquid.

Sintering is not simply an alternative to melting. It is a unique thermal process that enables the creation of parts from materials with exceptionally high melting points or complex compositions, unlocking geometries and properties that are often impossible to achieve through conventional casting.

How Sintering Works: The Core Mechanism

To understand why sintering is so powerful, we must look at how it transforms loose powder into a dense, solid component. The process is a fascinating interplay of temperature, pressure, and atomic movement.

From Powder to Part

The process begins with a material in powder form. This powder is often compressed into a desired shape, known as a "green compact," which is fragile but holds its form. In additive manufacturing, this "compact" is formed layer by layer.

The Role of Heat

The green compact is heated in a furnace to a specific temperature, typically around 70-90% of the material's absolute melting point. This heat provides the thermal energy needed to activate the bonding process without causing a complete phase change to liquid.

Atomic Diffusion and Bonding

At this elevated temperature, atoms on the surfaces of the powder particles become highly mobile. They begin to migrate across the boundaries between adjacent particles, creating small "necks" or bridges. As the process continues, these necks grow, pulling the particles closer together, reducing the empty space (porosity) between them, and causing the entire part to densify and shrink into a solid mass.

Key Applications: Where Sintering Excels

Sintering is not a one-size-fits-all solution. It shines in specific applications where other methods are impractical or fail to deliver the required performance.

Refractory Metals

Materials like tungsten and molybdenum have melting points so high that melting and casting them is extremely difficult and energy-intensive. Sintering allows these metals to be formed into solid parts (like high-temperature furnace elements or electrical contacts) at more manageable temperatures.

Additive Manufacturing (3D Printing)

Processes like Direct Metal Laser Sintering (DMLS) or Selective Laser Sintering (SLS) are fundamentally based on this principle. A high-power laser selectively sinters thin layers of metal or polymer powder, one on top of the other, to build incredibly complex and intricate shapes that would be impossible to machine or cast.

Ceramics and Cermets

Nearly all advanced ceramics (like those used in electronics or armor) and cermets (ceramic-metal composites like carbide cutting tools) are produced via sintering. These materials often decompose before they melt, making sintering the only viable method for consolidation.

Understanding the Advantages and Trade-offs

Like any engineering process, sintering has a distinct profile of benefits and limitations. Acknowledging these is crucial for making an informed decision.

Advantage: Material Versatility

Sintering makes it possible to create custom alloys and composite materials. By mixing different types of powders before the process begins, you can create materials with tailored properties, such as high hardness combined with good toughness.

Advantage: Net-Shape Complexity

Especially when combined with 3D printing, sintering can produce parts that are at or very near their final dimensions ("net-shape"). This ability to create complex internal channels, latticework, and organic shapes dramatically reduces the need for secondary machining operations.

Trade-off: Inherent Porosity

Achieving 100% density is very difficult and expensive. Most sintered parts retain a small amount of residual porosity. While often negligible, this can be a limiting factor for applications subjected to very high fatigue, as pores can act as stress concentration points.

Trade-off: Dimensional Control

As the powder particles fuse and the part densifies, it shrinks. This shrinkage must be precisely predicted and controlled to achieve accurate final dimensions, which adds a layer of complexity to the design and process control.

Making the Right Choice for Your Project

Choosing sintering depends entirely on your material, geometry, and performance requirements.

- If your primary focus is working with extremely high-temperature materials: Sintering is often the only practical consolidation method for refractory metals like tungsten and molybdenum.

- If your primary focus is creating highly complex parts with internal features: Additive manufacturing techniques that rely on sintering offer unparalleled geometric freedom compared to casting or subtractive machining.

- If your primary focus is cost-effective mass production of small metal parts: Traditional press-and-sinter powder metallurgy is a highly competitive process for components like gears and bearings.

Understanding sintering empowers you to select the right tool to solve challenging material science and design problems.

Summary Table:

| Sintering Aspect | Key Detail |

|---|---|

| Process | Fuses powder particles using heat and pressure, below the melting point. |

| Key Mechanism | Atomic diffusion creates bonds between particles, leading to densification. |

| Primary Applications | Refractory metals (tungsten), additive manufacturing (3D printing), ceramics & cermets. |

| Main Advantages | Material versatility, ability to create complex net-shape parts. |

| Key Considerations | Inherent porosity, precise control of dimensional shrinkage required. |

Ready to leverage sintering for your advanced manufacturing projects?

KINTEK specializes in the lab equipment and consumables that support sintering R&D and production. Whether you are developing new materials with high melting points or creating complex parts via additive manufacturing, our expertise and products can help you achieve precise thermal processing and superior results.

Contact our experts today to discuss how we can support your laboratory's sintering needs and drive your innovations forward.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Sintering Brazing Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of sputter coater? For High-Quality Thin Film Deposition & SEM Sample Prep

- How to start a lab grown diamond business? Choose the Right Model for Success

- Why is KBr and NaCl used in IR spectroscopy? Achieve Clear, Accurate Sample Analysis

- What are the applications of thin film technology? Powering Electronics, Energy, and Innovation

- What is potassium bromide made of? Discover the Ionic Compound Powering Labs and Veterinary Care

- Can a diamond tester be wrong? Yes, and here’s why you need more than one test

- How does carburizing work? Achieve Superior Surface Hardness and Core Toughness

- Is pyrolysis renewable or nonrenewable? The Answer Lies in Your Feedstock