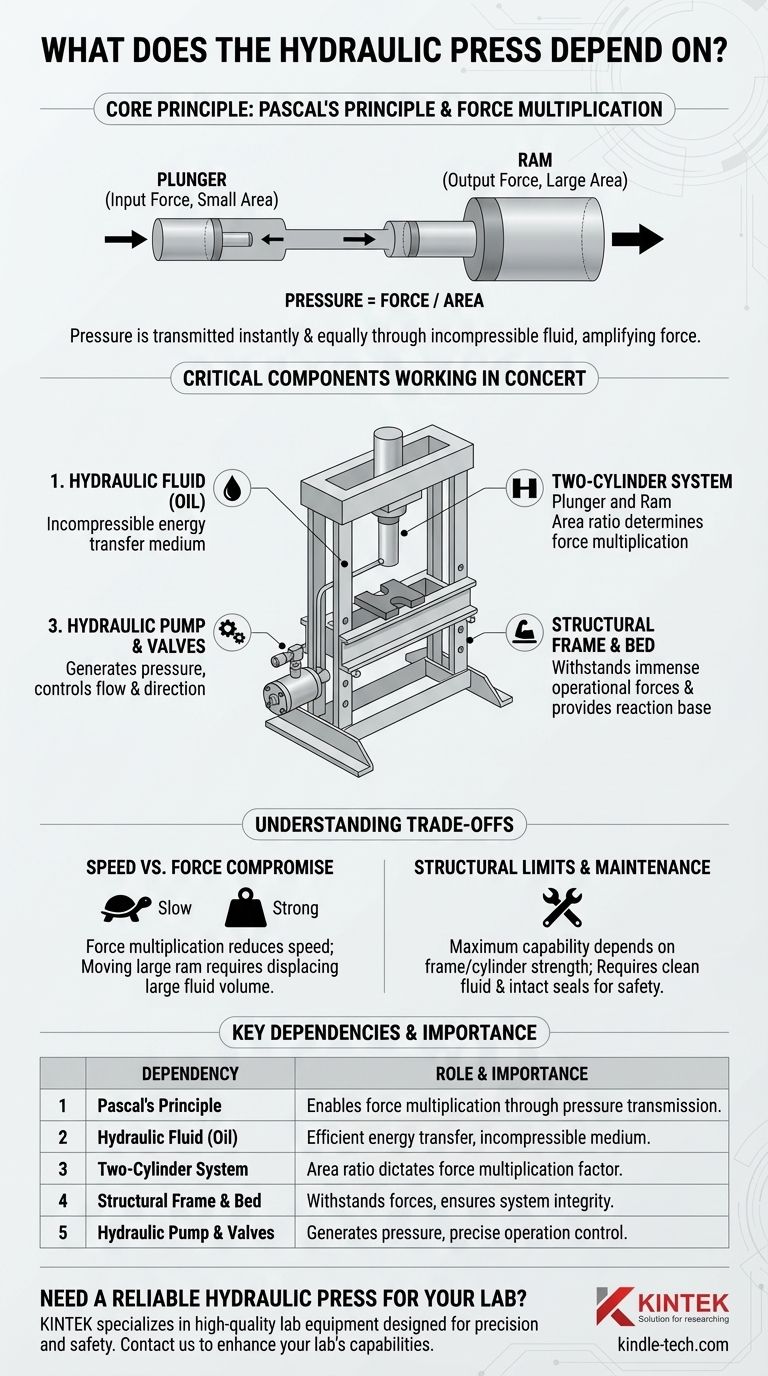

At its core, a hydraulic press depends on a fundamental law of physics and a few key mechanical components working in concert. It operates using Pascal's Principle, which allows a small force applied to a small area to be multiplied into a massive force over a larger area. This force is transmitted instantly and evenly through an incompressible fluid, typically oil.

The power of a hydraulic press does not come from the pump or the fluid itself, but from the multiplication of force achieved by applying pressure across two cylinders of different sizes. This core principle dictates the design and capability of the entire system.

The Core Principle: Force Multiplication

A hydraulic press is a direct application of fluid mechanics. Understanding the principle is more important than memorizing the parts, as the principle dictates why the parts are necessary.

Pascal's Principle in Action

Pascal's Principle states that pressure applied to an enclosed, incompressible fluid is transmitted equally throughout the fluid. The formula is Pressure = Force / Area.

In a hydraulic press, a small force is applied to a small piston (the plunger). This creates pressure in the hydraulic fluid. That same pressure then acts on a much larger piston (the ram), generating a proportionally larger output force.

For example, if the ram has 100 times the surface area of the plunger, the force exerted by the ram will be 100 times the force applied to the plunger.

The Critical Role of Hydraulic Fluid

The system depends on a fluid that is nearly incompressible. This is why hydraulic oil is used instead of a gas like air.

Because the oil doesn't compress, it efficiently transfers energy from the plunger to the ram. Any compression would result in a loss of power and a spongy, ineffective press.

The Essential Mechanical Components

While the principle is simple, its execution requires a robust set of engineered components, each with a specific job.

The Two-Cylinder System (Plunger and Ram)

This is the heart of the press. It consists of two interconnected cylinders, each with a piston.

- The Plunger: The smaller cylinder where the initial, smaller force is applied.

- The Ram: The larger cylinder that delivers the multiplied, massive output force to do the work.

The size ratio between the ram and the plunger directly determines the force multiplication factor of the press.

The Power System (Hydraulic Pump)

Something must generate the initial pressure. A hydraulic pump (often housed in a hydraulic power unit) is used to push fluid into the plunger cylinder. The power of this pump determines how quickly the pressure can be built and how fast the ram can move.

The Frame and Bed

The immense forces generated by the ram must be contained. The frame is the main structure that holds all components together and withstands the operational force.

The bed (or bolster) is the solid, flat surface that supports the material being worked on, providing the equal and opposite reaction force required for pressing. Without a sufficiently strong frame and bed, the press would simply push itself apart.

The Control System (Valves)

The flow of hydraulic fluid must be managed precisely. Directional control valves are used to start, stop, and direct the fluid, allowing the operator to extend the ram, retract it, or hold it in a specific position.

Understanding the Trade-offs

A hydraulic press is a powerful tool, but its design involves inherent compromises that are critical to understand for safe and effective operation.

The Speed vs. Force Compromise

The multiplication of force comes at a direct cost: speed.

To move the large ram a short distance, a very large volume of fluid must be displaced. This means the small plunger must travel a much longer distance to push that fluid. As a result, hydraulic presses are incredibly strong but typically very slow.

Structural and Pressure Limits

Every component has a breaking point. The references note both a "maximum recommended power" and a "maximum allowed power."

This highlights that the press's ultimate capability depends on the material strength of its frame, cylinder walls, and seals. Exceeding the recommended pressure risks permanent damage or catastrophic failure.

System Maintenance

Hydraulic systems are complex. They rely on clean fluid, intact seals, and properly functioning pumps and valves. Leaks, contamination, or worn seals can drastically reduce performance and create significant safety hazards.

Making the Right Choice for Your Goal

Understanding these dependencies allows you to operate a press effectively and safely, with a clear grasp of its capabilities and limitations.

- If your primary focus is maximizing force: Your limit is the system's maximum pressure rating and the surface area of the ram.

- If your primary focus is operational speed: You must use a more powerful pump to move a higher volume of fluid, but this does not increase the maximum force.

- If your primary focus is safety and longevity: Always operate within the manufacturer's recommended pressure limits, as the structural frame and hydraulic components are the ultimate points of failure.

By understanding how these elements depend on one another, you can use the hydraulic press not just as a machine, but as a precise and predictable tool.

Summary Table:

| Key Dependency | Role & Importance |

|---|---|

| Pascal's Principle | Fundamental physics law enabling force multiplication through pressure transmission in fluid. |

| Hydraulic Fluid (Oil) | Incompressible medium that efficiently transfers energy; critical for system performance. |

| Two-Cylinder System (Plunger & Ram) | Heart of the press; the area ratio between ram and plunger determines the force multiplication factor. |

| Structural Frame & Bed | Withstands immense operational forces; provides the reaction force for pressing. |

| Hydraulic Pump & Valves | Generates initial pressure and controls fluid flow for precise operation. |

Need a Reliable Hydraulic Press for Your Laboratory?

Understanding the dependencies of a hydraulic press is the first step; acquiring the right equipment is the next. KINTEK specializes in high-quality lab equipment, including robust hydraulic presses designed for precision, safety, and longevity. Our presses are engineered with superior components to ensure optimal force multiplication and consistent performance for all your pressing needs.

Let us help you enhance your lab's capabilities. Contact KINTEK today to discuss your specific requirements and discover the perfect hydraulic press solution for your laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy