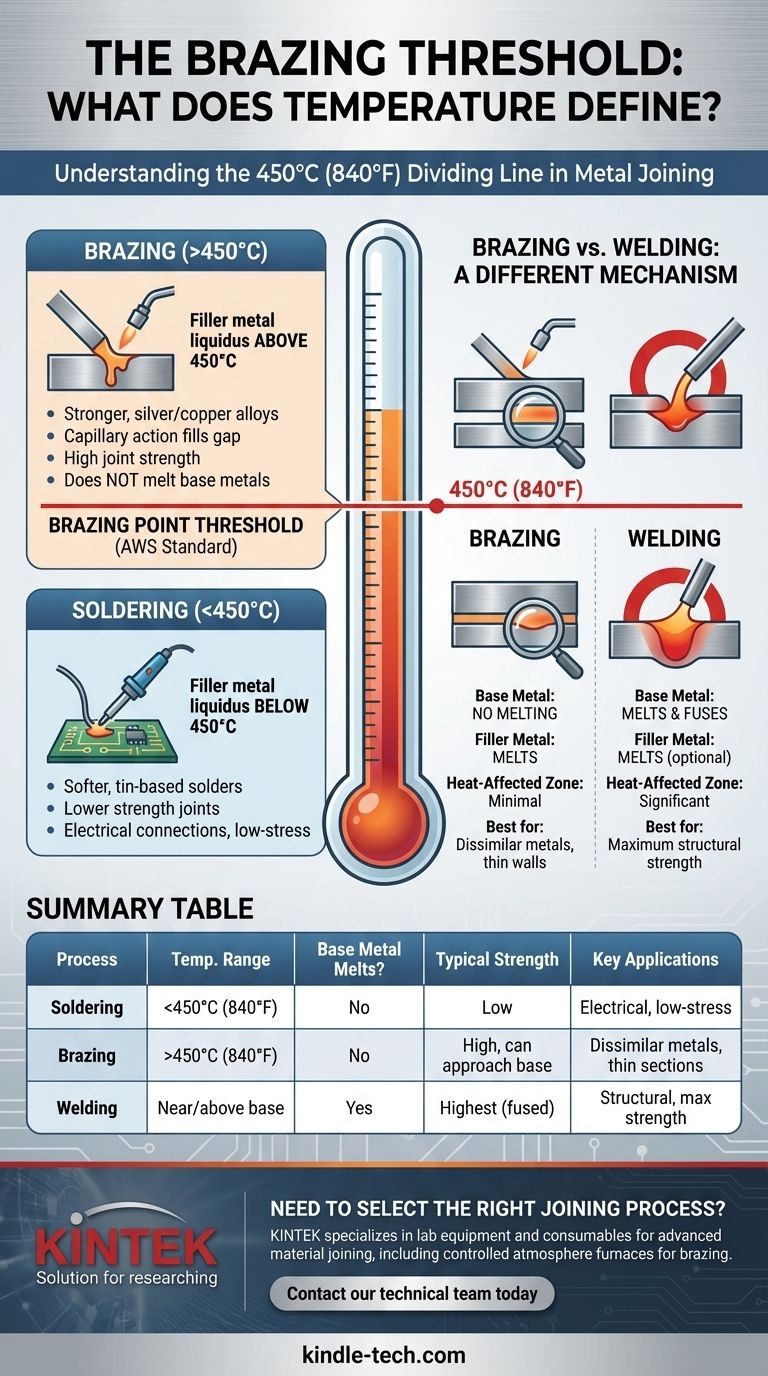

To be classified as brazing, the process must use a filler metal that has a liquidus temperature above 450°C (840°F). This specific threshold, established by the American Welding Society, is the internationally recognized dividing line between brazing and the lower-temperature process of soldering. However, the temperature itself is only part of the story; it's a marker for a fundamentally different class of materials and joint strengths.

The core distinction is not just the temperature, but what it enables. Brazing operates in a "sweet spot" hot enough to use strong, high-performance filler alloys, but cool enough to join metals without melting and potentially damaging them, unlike welding.

The Defining Line: Brazing vs. Soldering

The most common point of confusion is the difference between soldering and brazing. While they appear similar, the temperature threshold creates a clear separation in both process and outcome.

The 450°C (840°F) Threshold

This number is the formal definition. Any joining process using a filler metal that melts below this point is soldering. Any process using a filler metal that melts above this point (but below the melting point of the base metals) is brazing.

This isn't an arbitrary line. It corresponds to a significant shift in the types of filler metal alloys that can be used, moving from softer, tin-based solders to stronger, silver- and copper-based brazing alloys.

How Filler Metal Works

Both brazing and soldering rely on capillary action. This is the physical phenomenon where a liquid is drawn into a narrow space, even against the force of gravity.

For a strong joint, the gap between the two base metal pieces must be precisely controlled. The heated filler metal then melts, is pulled into this gap, and bonds to the surfaces of the base metals upon cooling.

Strength and Application Differences

The higher temperatures of brazing allow for the use of filler metals with significantly higher strength. A properly brazed joint can have a tensile strength that approaches, and sometimes exceeds, that of the base metals being joined.

Soldered joints, by contrast, are much weaker. They are suitable for electrical connections or low-stress plumbing but are not used for structural applications where strength is a primary concern.

Brazing vs. Welding: A Different Mechanism

The other major joining process is welding, which is often confused with brazing but operates on a completely different principle.

Melting vs. Not Melting the Base Metal

This is the most critical distinction. In welding, the edges of the base metals are melted and fused together, often with the addition of a molten filler material. The final joint is a contiguous, solidified piece of the same (or very similar) metal.

In brazing, only the filler metal melts. The base metals are heated, but they never reach their melting point. Brazing essentially acts like a very strong metallic glue, bonding the pieces together without altering their fundamental state.

Impact on Material Properties

Because welding involves much higher localized temperatures, it creates a significant heat-affected zone (HAZ). This can alter the temper, hardness, and internal stresses of the base metals, sometimes weakening them.

Brazing uses lower, more evenly distributed heat. This makes it the ideal process for joining heat-treated components, thin-walled tubes, or dissimilar metals (like copper to steel) that cannot be easily welded together.

Understanding the Trade-offs

While powerful, brazing is not a universal solution. Success depends on understanding its specific requirements and limitations.

The "Gap" is Critical

Capillary action only works if the clearance between the parts is correct. A gap that is too wide will not allow the filler metal to be drawn in and fill the joint completely. A gap that is too narrow will prevent the filler metal from entering at all.

Base Metal Cleanliness

Brazing is highly intolerant of surface contaminants like oils, grease, and oxides. The surfaces must be meticulously cleaned before heating. A chemical flux or a controlled, oxygen-free atmosphere is almost always required to prevent re-oxidation during heating and to help the filler metal flow.

The Strength Limitation

While a brazed joint is very strong, its ultimate strength is typically limited by the shear strength of the filler alloy itself. For applications demanding the absolute maximum structural integrity, a properly executed weld will almost always create a stronger connection.

Making the Right Choice for Your Project

Choosing the correct process requires aligning the method with the unique demands of your application.

- If your primary focus is joining dissimilar metals or thin sections: Brazing is the ideal choice due to its lower heat input and ability to bond different materials without melting them.

- If your primary focus is maximum joint strength and integrity: Welding provides the strongest possible bond by fusing the base metals into a single piece.

- If your primary focus is electrical conductivity or low-stress sealing: Soldering is the correct, cost-effective process that avoids heat damage to sensitive components.

Ultimately, understanding the role of temperature allows you to select the process that best balances strength, material integrity, and complexity for your goal.

Summary Table:

| Process | Temperature Range | Base Metal Melts? | Typical Joint Strength | Key Applications |

|---|---|---|---|---|

| Soldering | Below 450°C (840°F) | No | Low | Electrical connections, low-stress plumbing |

| Brazing | Above 450°C (840°F) | No | High, can approach base metal strength | Joining dissimilar metals, thin sections, heat-sensitive components |

| Welding | Near/above base metal melting point | Yes | Highest (fused base metals) | Structural applications requiring maximum strength |

Need to Select the Right Joining Process for Your Materials?

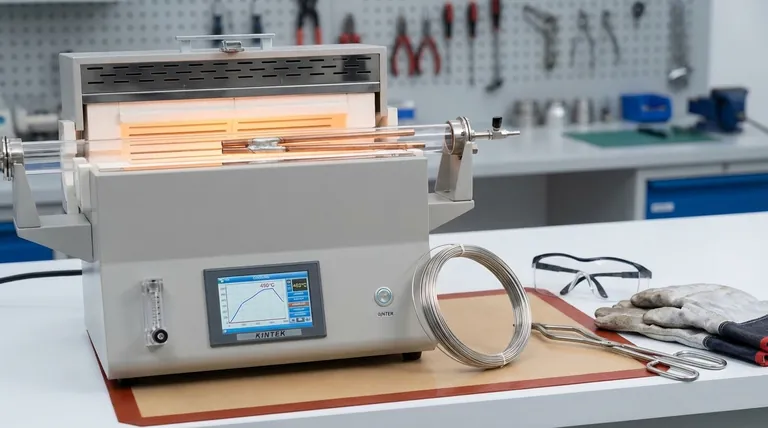

Understanding the critical temperature difference between brazing, soldering, and welding is key to achieving strong, reliable bonds without damaging your components. KINTEK specializes in providing the precise lab equipment and consumables needed for advanced material joining processes, including controlled atmosphere furnaces ideal for brazing applications.

Our experts can help you select the right tools to ensure optimal temperature control, cleanliness, and joint integrity for your specific project. Let us help you achieve superior results.

Contact our technical team today to discuss your application needs!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How do tube furnaces work? A Guide to Precision High-Temperature Processing