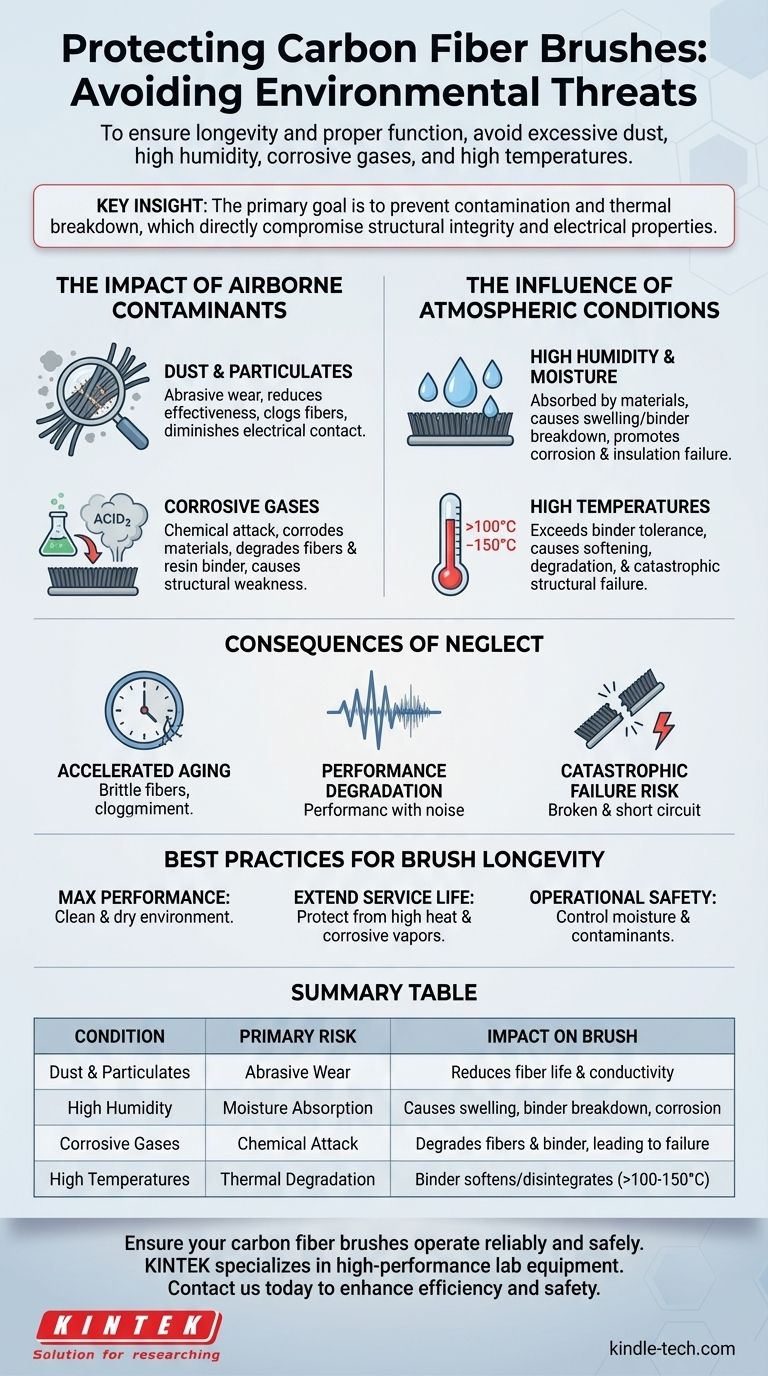

To ensure their longevity and proper function, carbon fiber brushes must be protected from four specific environmental threats: excessive dust, high humidity, corrosive gases, and high temperatures. These conditions can physically and chemically degrade the delicate fibers and binding materials, leading to premature failure and unreliable performance.

While known for their durability and conductivity, carbon fiber brushes are not immune to their environment. The primary goal is to prevent contamination and thermal breakdown, which directly compromise the brush's structural integrity and electrical properties.

The Impact of Airborne Contaminants

The air surrounding your carbon fiber brush can contain particles and chemicals that actively work to degrade it.

Dust and Particulates

Dust and other airborne particulates act as an abrasive agent. They can wear down the fine carbon fibers, reducing the brush's effectiveness and lifespan.

This buildup can also clog the spaces between fibers, which significantly diminishes the surface area available for electrical contact and reduces overall conductivity.

Corrosive Gases

Chemicals in the air, such as acid mist or chlorine gas, are particularly damaging. These substances can initiate a chemical reaction that corrodes the brush materials.

This corrosion attacks not only the carbon fibers but also the resin binder that holds them together, leading to structural weakness and eventual disintegration.

The Influence of Atmospheric Conditions

Seemingly benign atmospheric factors like humidity and heat can cause significant and often irreversible damage over time.

High Humidity and Moisture

Moisture in the air is a critical threat. It can be absorbed by the brush materials, leading to swelling or a breakdown of the binder.

Furthermore, humidity promotes corrosion on any associated metallic components and can create unintended electrical pathways, increasing the risk of insulation failure and short circuits.

High Temperatures

Excessive heat is one of the most severe threats to a carbon fiber brush. Most brushes use a polymer or resin to bind the fibers, which has a specific temperature tolerance.

Exceeding this limit, typically around 100°C to 150°C (212°F to 302°F), will cause the binder to soften, degrade, or burn. This results in a catastrophic loss of structural integrity, causing the fibers to splay or fall out.

Understanding the Consequences of Neglect

Failing to control the operating environment leads to predictable and compounding failure modes that undermine the brush's purpose.

Accelerated Aging

Each of these negative conditions—dust, chemicals, moisture, and heat—acts as a stressor that accelerates the natural aging process of the brush's composite materials, making them brittle and fragile.

Electrical Performance Degradation

The core function of the brush is reliable electrical contact. Contamination and corrosion create resistance and inconsistency, leading to poor performance, signal noise, or intermittent failures.

Catastrophic Failure Risk

The most serious outcome is a complete structural or insulation failure. A disintegrating brush can damage surrounding components, while insulation failure can cause dangerous electrical shorts, posing a risk to the entire system.

Best Practices for Brush Longevity

Your maintenance strategy should be guided by your most critical operational goal.

- If your primary focus is maximum performance: Keep the operating environment exceptionally clean and dry to ensure the most consistent and reliable electrical contact.

- If your primary focus is extending service life: Prioritize protecting the brush from high temperatures and corrosive vapors, as these factors cause the most severe and irreversible physical damage.

- If your primary focus is operational safety: Emphasize the control of moisture and airborne contaminants to prevent the critical risk of insulation failure and electrical shorts.

Proactive control of the operating environment is the most effective way to ensure the long-term reliability of your carbon fiber brushes.

Summary Table:

| Environmental Condition | Primary Risk | Impact on Brush |

|---|---|---|

| Dust & Particulates | Abrasive Wear | Reduces fiber life & conductivity |

| High Humidity | Moisture Absorption | Causes swelling, binder breakdown, corrosion |

| Corrosive Gases | Chemical Attack | Degrades fibers & binder, leading to failure |

| High Temperatures | Thermal Degradation | Binder softens/disintegrates (>100-150°C) |

Ensure your carbon fiber brushes operate reliably and safely. KINTEK specializes in high-performance lab equipment and consumables, offering expert solutions to protect your critical components from environmental damage. Contact us today to discuss your specific needs and enhance your laboratory's efficiency and safety.

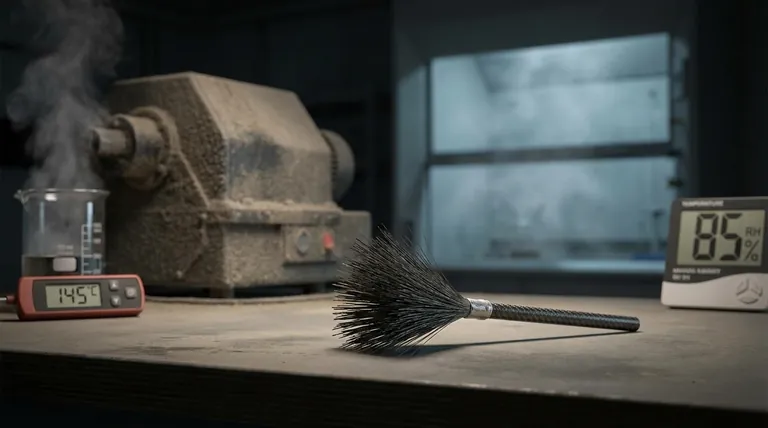

Visual Guide

Related Products

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- How should an appropriate PTFE cleaning basket be selected? A Guide to Efficient and Safe Lab Cleaning

- What should be monitored during the cleaning process when using a PTFE cleaning basket? Ensure Reliable Results & Prevent Damage

- What are the analytical used in laboratory? Choose the Right Tool for Your Lab's Needs

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C