Selecting the right PTFE cleaning basket is a critical decision based on three primary factors: the physical characteristics of the items being cleaned, the dimensions of your cleaning equipment, and the demands of your cleaning protocol. For small, delicate components, a fine-mesh basket is essential to prevent loss, whereas larger, heavier parts demand a basket with a greater load-bearing capacity and more open construction for fluid flow.

The selection of a suitable basket is only the starting point. The true reliability and effectiveness of your cleaning process hinge on a holistic approach that includes proper operational use, disciplined inspection, and preventative maintenance.

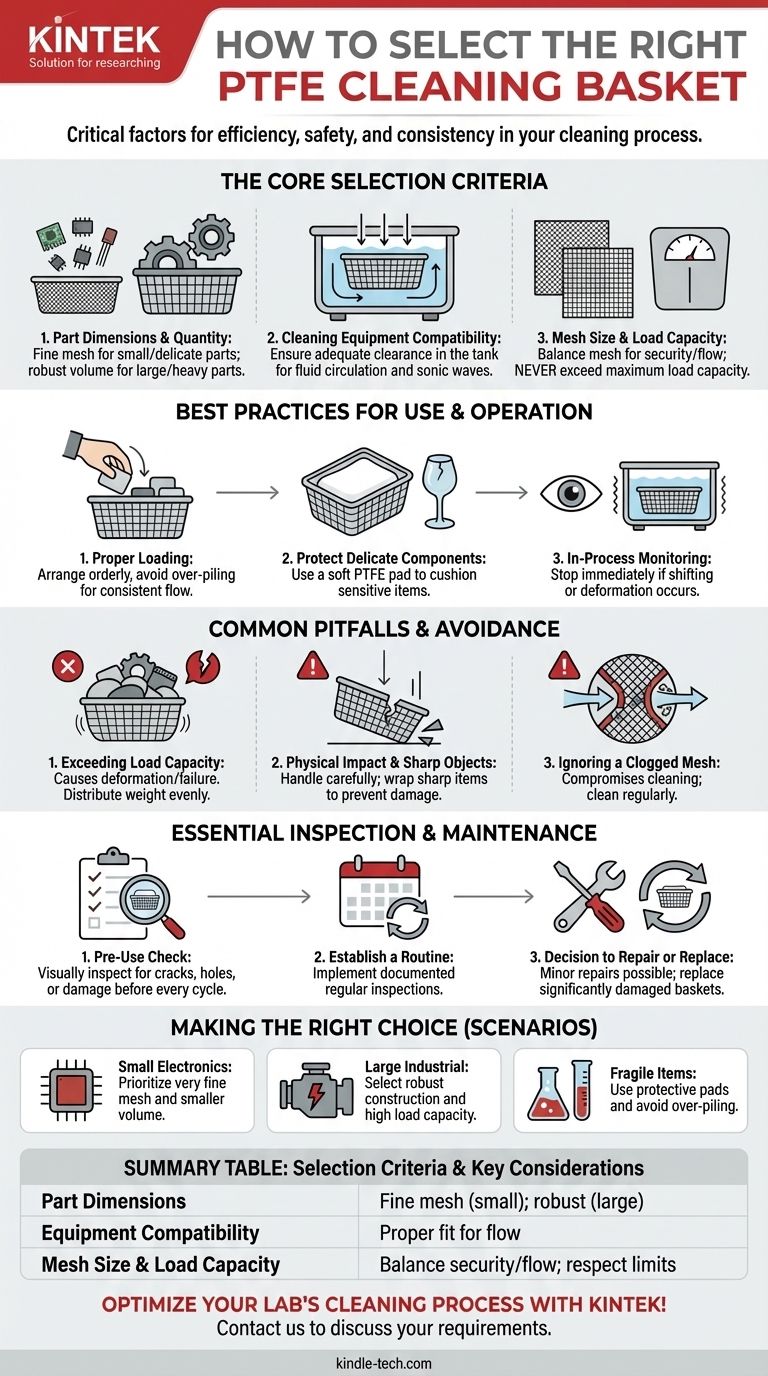

The Core Selection Criteria

To ensure your cleaning process is both efficient and safe, your selection must be deliberate. The basket is not just a container; it is an integral part of the cleaning system.

Part Dimensions and Quantity

The physical size and volume of the parts you are cleaning are the most fundamental considerations.

For small, high-precision items like electronic components, you need a basket with a fine mesh to prevent them from falling through.

Conversely, cleaning larger industrial or chemical parts requires a basket with sufficient volume and structural integrity to hold them securely without crowding.

Cleaning Equipment Compatibility

The basket must function correctly within your existing equipment, such as an ultrasonic cleaning tank.

Measure the internal dimensions of your cleaning tank and ensure the basket fits with adequate clearance on all sides. This space is crucial for the effective circulation of cleaning solutions and, in ultrasonic systems, for the propagation of sonic waves.

Mesh Size and Load Capacity

The mesh size directly impacts both part security and cleaning efficacy. A finer mesh secures smaller parts, while a larger mesh allows for maximum fluid flow and faster drainage, which is ideal for robust components.

Simultaneously, you must verify the basket's maximum load capacity. Never exceed this limit, as overloading can lead to deformation or structural failure, jeopardizing both the parts and the equipment.

Best Practices for Use and Operation

Once selected, how you use the basket determines its performance and lifespan. Careless operation can undermine even the most well-chosen tool.

Proper Loading Technique

Arrange items in an orderly fashion within the basket. Avoid over-piling, as this can mask surfaces and prevent the cleaning solution from reaching all critical areas.

Ensure there is enough space between items for the solution to flow freely, guaranteeing a thorough and consistent cleaning process.

Protecting Delicate Components

For fragile or precision parts, place a soft PTFE pad at the bottom of the basket. This simple step provides a cushion, protecting sensitive items from impact damage during handling and the cleaning cycle itself.

In-Process Monitoring

Actively observe the cleaning process. If you notice any anomalies, such as the basket shifting position during ultrasonic cleaning or any signs of deformation, stop the process immediately.

A basket that moves excessively can lead to inefficient cleaning or potential damage. It should be repositioned and secured before continuing.

Common Pitfalls and How to Avoid Them

Understanding potential failure points is key to maintaining a reliable cleaning operation and extending the life of your equipment.

Exceeding Load Capacity

Overloading the basket is a frequent cause of failure. Always respect the manufacturer's stated load capacity and ensure the weight is distributed evenly. Concentrating weight in one area creates localized stress and can lead to warping or cracking.

Physical Impact and Sharp Objects

PTFE is a durable material, but it is not immune to damage from severe impacts. Handle the basket carefully and avoid dropping it.

Furthermore, do not place items with sharp edges or corners directly into the basket. If necessary, wrap them in a soft, compatible material to prevent them from scratching or puncturing the basket's surface.

Ignoring a Clogged Mesh

Over time, the basket's mesh can become clogged with residue, which severely restricts the flow of cleaning solution. A clogged mesh compromises cleaning effectiveness and should be addressed immediately as part of your maintenance routine.

Essential Inspection and Maintenance

A proactive approach to maintenance prevents unexpected failures and ensures consistent performance.

The Pre-Use Check

Before every cleaning cycle, perform a quick visual inspection. Look for any cracks, holes, or signs of damage. Check that the mesh is clear and that handles or other components are secure. A damaged basket should be removed from service immediately.

Establishing a Routine

Implement a regular, documented inspection schedule, such as monthly or more frequently for heavy-use applications. This allows you to catch signs of wear, deformation, or chemical degradation before they become critical failures.

The Decision to Repair or Replace

Minor cracks can sometimes be addressed using a specialized PTFE repair agent. This involves thoroughly cleaning the damaged area, roughening the surface, and applying the agent.

However, for significant damage that compromises the basket's structural integrity, replacement is the only safe option. Repairing a critically damaged basket risks failure during operation.

Making the Right Choice for Your Process

Your specific application dictates the final decision. Use these guidelines to align your choice with your operational goals.

- If your primary focus is cleaning small, precise electronic components: Prioritize a basket with a very fine mesh to prevent part loss and a smaller volume that fits your specific equipment.

- If your primary focus is cleaning larger, heavy chemical or industrial parts: Select a basket with robust construction, a high load-bearing capacity, and a larger mesh size for optimal fluid dynamics.

- If your primary focus is handling fragile, high-value items: Ensure you use protective measures like soft PTFE pads and avoid over-piling to prevent any risk of impact damage during the process.

A well-chosen and properly maintained PTFE basket is a critical investment in the consistency and safety of your cleaning operations.

Summary Table:

| Selection Criteria | Key Considerations |

|---|---|

| Part Dimensions | Fine mesh for small parts; robust structure for large parts |

| Equipment Compatibility | Ensure proper fit in cleaning tank for fluid flow |

| Mesh Size & Load Capacity | Balance part security with fluid dynamics; respect weight limits |

Optimize your lab's cleaning process with the right equipment from KINTEK!

Struggling to select the perfect PTFE cleaning basket for your delicate components or heavy-duty parts? KINTEK specializes in high-quality lab equipment and consumables designed to meet your specific needs. Our PTFE baskets ensure maximum cleaning efficiency, durability, and compatibility with your existing systems.

Contact us today to discuss your requirements and let our experts help you enhance the safety and consistency of your cleaning operations!

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Custom PTFE Teflon Parts Manufacturer for Hollow Etching Flower Basket ITO FTO Developing Glue Removal

People Also Ask

- What inspection should be performed on a PTFE cleaning basket before use? A 3-Step Protocol for Safe, Effective Cleaning

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- What material is a PTFE cleaning basket made of? Unlocking Superior Chemical and Thermal Resistance

- What are the common specifications and shapes for PTFE cleaning baskets? Maximize Chemical Purity & Process Integrity

- What is the maximum operating temperature for a PTFE cleaning basket? Avoid Catastrophic Failure at 260°C