In essence, a good refractory is a material engineered to withstand extreme conditions inside a high-temperature process. It must resist heat, chemical attack, and mechanical stress, all while ensuring the process runs efficiently and safely. The key properties include high refractoriness, low thermal conductivity, and strong resistance to thermal shock and chemical corrosion.

The selection of a refractory is never about finding a material that excels at one thing. It is about identifying the specific operational challenges—be it chemical attack, temperature fluctuation, or physical wear—and choosing a material with the optimal balance of properties to meet those demands.

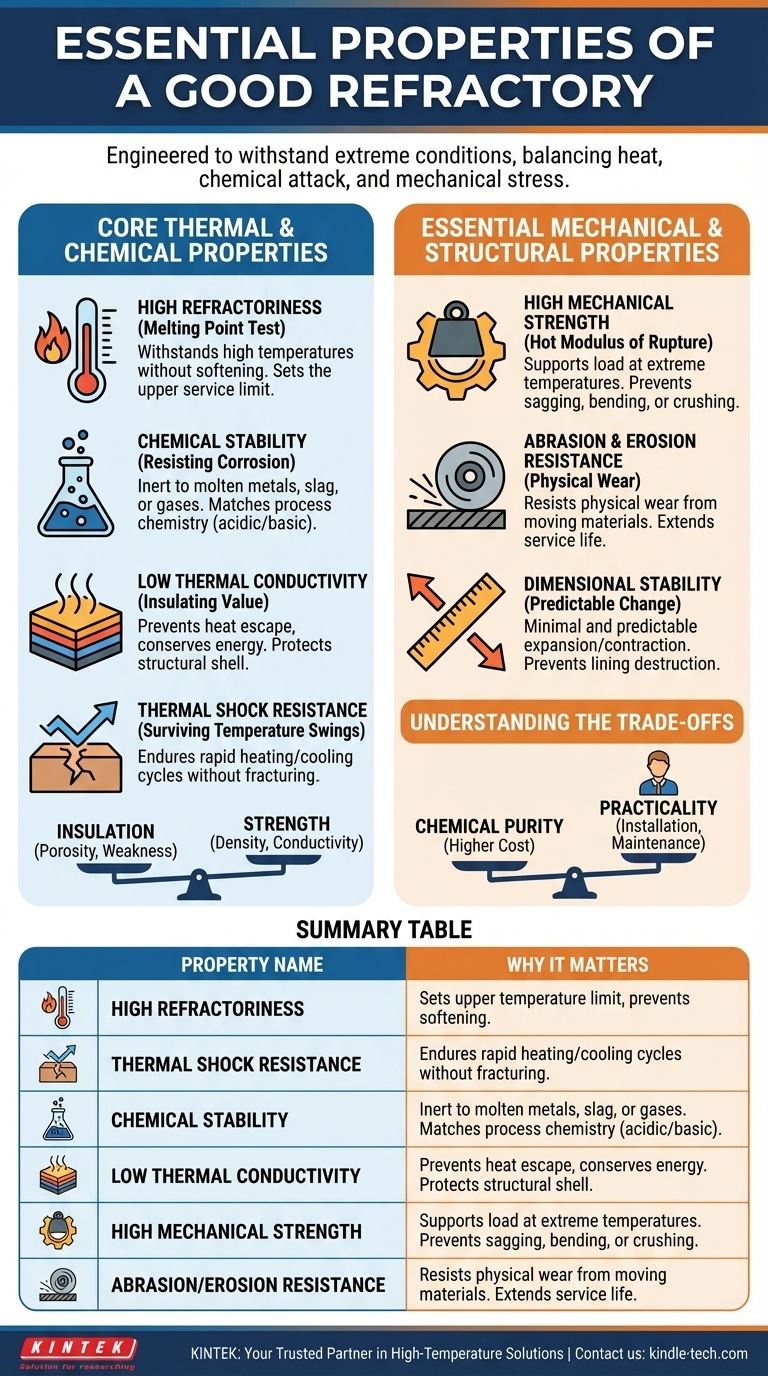

Core Thermal and Chemical Properties

The primary function of a refractory is to contain heat and resist the process environment. Its thermal and chemical characteristics are the foundation of its performance.

High Refractoriness (The Melting Point Test)

This is the most fundamental property. Refractoriness is the ability of a material to withstand high temperatures without softening or deforming under a specific load.

It represents the absolute upper limit of the material's service temperature and is the first qualifier for any high-temperature application.

Chemical Stability (Resisting Corrosion)

Industrial processes often involve molten metals, slag, or aggressive hot gases that can chemically attack the refractory lining.

A good refractory must be chemically inert to the specific substances it contains. For example, an acidic slag requires an acidic refractory (like silica), while a basic slag requires a basic refractory (like magnesia) to prevent rapid corrosion.

Low Thermal Conductivity (Insulating Value)

This property dictates how well the refractory prevents heat from escaping the furnace or vessel.

Materials with low thermal conductivity are excellent insulators. They are critical for conserving energy, reducing fuel costs, and protecting the outer structural shell from heat damage.

Thermal Shock Resistance (Surviving Temperature Swings)

Thermal shock is the stress a material endures during rapid heating or cooling, which can cause it to crack and fail.

Excellent thermal shock resistance ensures the refractory lining can withstand the operational cycles of a furnace—startup, shutdown, and batch processing—without fracturing.

Essential Mechanical and Structural Properties

A refractory lining is not just a thermal barrier; it is a structural component that must maintain its integrity under significant physical stress.

High Mechanical Strength

Refractories must support their own weight and often the weight of the product being processed, all while at extreme temperatures.

This property, often measured as Hot Modulus of Rupture (HMOR), ensures the material does not sag, bend, or crush under load when heated.

Abrasion and Erosion Resistance

Many processes involve the movement of molten materials, turbulent gases, or abrasive solids that can physically wear away the refractory lining.

A durable refractory must be hard and dense enough to resist this physical erosion, which is critical for extending the service life of the lining in high-velocity environments.

Dimensional Stability

All materials expand when heated and contract when cooled. A good refractory must exhibit predictable and minimal dimensional change across its operating temperature range.

Excessive expansion can destroy the lining by creating immense pressure, while excessive shrinkage can open joints that lead to catastrophic failures.

Understanding the Trade-offs

No single refractory material is perfect for every situation. Choosing the right one involves balancing competing properties, which often have an inverse relationship.

Insulation vs. Strength

Highly insulating refractories, such as lightweight insulating firebricks, achieve their low thermal conductivity through high porosity (trapped air).

This same porosity makes them mechanically weaker than dense, high-strength bricks, which are better conductors of heat.

Chemical Purity vs. Cost

Materials with higher purity, like 99% alumina, generally offer superior refractoriness and chemical resistance.

However, this increased performance comes at a significantly higher cost. The goal is to select a material with sufficient purity for the application without over-engineering and inflating the budget.

Ease of Installation and Maintenance

The ideal material must also be practical. Monolithic refractories (castables or gunning mixes) can be installed quickly in complex shapes but may require specialized curing.

Bricks, on the other hand, offer predictable performance but are more labor-intensive to install. The ease of future repairs is also a critical factor in long-term operational cost.

Making the Right Choice for Your Application

Your final selection should be guided by a clear understanding of your primary operational challenge.

- If your primary focus is containing molten metal or corrosive slag: Prioritize chemical stability and ensure the refractory type (e.g., acidic, basic) matches the process chemistry.

- If your primary focus is maximizing energy efficiency: Select materials with the lowest possible thermal conductivity that still meet the required mechanical strength for the location.

- If your primary focus is withstanding rapid thermal cycles: Thermal shock resistance is your most critical property to prevent cracking and premature failure.

- If your primary focus is structural integrity under load: You must evaluate the hot mechanical strength and abrasion resistance to prevent physical collapse or wear.

Ultimately, the best refractory is not the one with the highest rating in a single property, but the one with the optimal balance for the specific demands of its environment.

Summary Table:

| Property | Why It Matters | Key Consideration |

|---|---|---|

| High Refractoriness | Withstands extreme heat without softening | Sets the upper temperature limit |

| Thermal Shock Resistance | Survives rapid heating/cooling cycles | Prevents cracking from temperature swings |

| Chemical Stability | Resists corrosion from slag, metals, gases | Must match process chemistry (acidic/basic) |

| Low Thermal Conductivity | Conserves energy and insulates effectively | Balances insulation needs with mechanical strength |

| High Mechanical Strength | Supports load at high temperatures | Prevents sagging, crushing (Hot Modulus of Rupture) |

| Abrasion/Erosion Resistance | Withstands physical wear from moving materials | Critical for extending service life |

Struggling to find the right refractory for your demanding application?

Selecting the optimal refractory is a complex balance of thermal, chemical, and mechanical properties. The wrong choice can lead to premature failure, safety risks, and costly downtime.

KINTEK is your trusted partner in high-temperature solutions. We specialize in supplying premium lab equipment and consumables, including refractories tailored to withstand your specific process challenges—whether it's extreme temperatures, corrosive environments, or rapid thermal cycling.

We help you:

- Extend Equipment Lifespan: By matching the perfect refractory material to your application, we maximize the longevity of your furnaces and reactors.

- Improve Process Efficiency: Our materials are engineered for optimal thermal insulation, reducing your energy consumption and operating costs.

- Enhance Safety and Reliability: Ensure your operations run smoothly with refractories that provide consistent performance under load.

Don't leave your critical processes to chance. Let our experts guide you to the ideal solution.

Contact KINTEL today for a personalized consultation and discover how our refractory solutions can protect your equipment and optimize your high-temperature processes.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Isostatic Molding Pressing Molds for Lab

- Custom PTFE Teflon Parts Manufacturer Grinding Bowl

People Also Ask

- How can you improve corrosion resistance? Extend Equipment Life with Proven Strategies

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- Why is platinum unreactive? The Atomic Secrets Behind Its Remarkable Stability