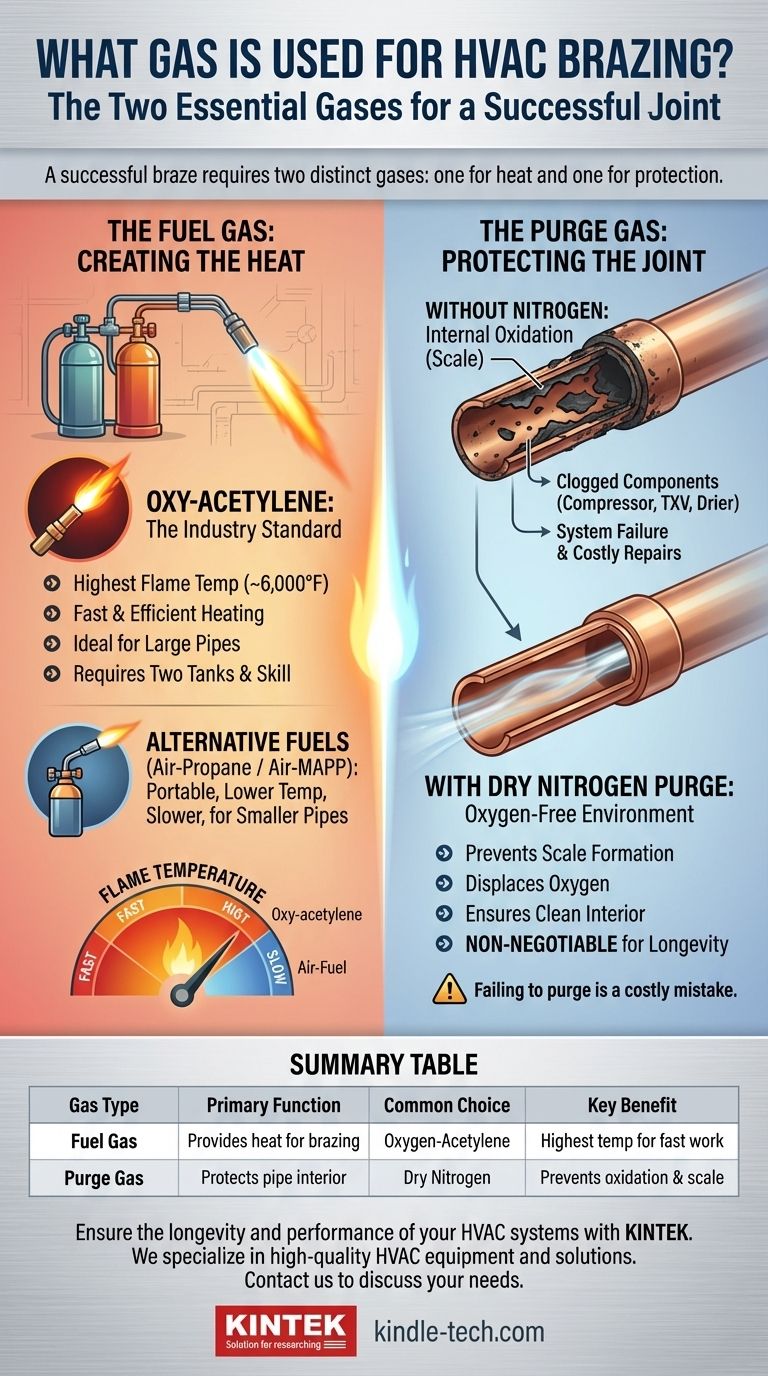

For HVAC brazing, the most common and effective fuel is an oxygen-acetylene mixture. This combination produces a flame hot enough to quickly and efficiently braze copper tubing. However, the fuel gas for creating heat is only half of the equation; an inert purge gas is also required to protect the inside of the system.

The critical takeaway is not just choosing a fuel gas for heat, but understanding that a successful, long-lasting braze requires two distinct gases: a fuel gas (like oxy-acetylene) for the torch and a purge gas (nitrogen) flowing inside the pipe to prevent catastrophic internal contamination.

The Two Essential Gases of Brazing

A professional HVAC braze isn't about a single gas, but two gases performing two separate, vital jobs. One creates the heat, and the other ensures the quality and longevity of the joint.

The Fuel Gas: Creating the Heat

The purpose of the fuel gas is to mix with oxygen and produce a flame hot enough to bring the base metals (usually copper) to the correct brazing temperature, which is above 840°F (450°C).

The industry standard is oxygen-acetylene. This combination provides the highest flame temperature (around 6,000°F), allowing technicians to heat the joint quickly, which minimizes heat transfer to sensitive system components.

Alternative fuels like air-propane or air-MAPP gas torches can also be used. These are often more portable and less expensive but produce a lower-temperature flame. They are suitable for smaller-diameter tubing but can be slow and inefficient on larger pipes or in windy conditions.

The Purge Gas: Protecting the Joint

While heating the outside of the copper pipe, the high temperature causes a chemical reaction with oxygen on the inside of the pipe. This creates a black scale called cupric oxide.

This internal oxidation is a major problem. The flakes of scale can break off once the system is running, traveling through the refrigerant lines and clogging or destroying critical components like the compressor, expansion valves (TXV), and filter driers.

To prevent this, technicians flow a low-pressure stream of an inert gas through the pipe during the brazing process. The industry-standard purge gas is dry nitrogen. The nitrogen displaces the oxygen inside the pipe, creating an oxygen-free environment and ensuring the inside of the joint remains clean and scale-free.

Understanding the Trade-offs

Choosing the right setup involves balancing speed, cost, and the quality of the final result. While the fuel gas is a choice, the purge gas is a necessity.

Oxy-Acetylene: The Standard for Speed and Power

This setup is favored by professionals for a reason. The intense heat allows for very fast work, which is crucial for productivity and for minimizing the risk of overheating nearby valves or controls. It is the only practical choice for larger commercial piping.

The trade-offs are cost and complexity. It requires two separate, heavy tanks (one oxygen, one acetylene) and a more expensive regulator and torch set. The high temperatures also demand greater skill and attention to safety.

Air-Fuel Torches: The Portable Alternative

Torches using MAPP gas or propane with ambient air are much lighter and simpler, requiring only a single fuel tank. This makes them convenient for small residential jobs or quick repairs on smaller lines.

The downside is a significantly lower flame temperature. Heating takes longer, increasing the risk of heat spreading to areas you don't want it. They may not be able to get larger pipes hot enough to achieve a proper braze, especially in outdoor conditions.

The Nitrogen Purge: A Non-Negotiable Requirement

There is no trade-off here. Failing to purge with nitrogen is the most common and costly mistake a technician can make. The cost of a nitrogen tank and regulator is insignificant compared to the cost of replacing a compressor destroyed by oxidation.

The process involves setting a very low flow rate—just 2-3 cubic feet per hour (CFH)—to gently displace the oxygen without creating enough pressure to blow out the molten filler metal.

How to Apply This to Your Project

Your choice of fuel gas can vary, but your commitment to a clean system cannot. Use this guide to determine the right approach.

- If your primary focus is professional efficiency: Use an oxy-acetylene torch for its speed and power on all pipe sizes, and always pair it with a regulated nitrogen purge.

- If your primary focus is small-scale residential repair: An air-MAPP torch may be sufficient for small lines (e.g., 3/8"), but you must still use a nitrogen purge to protect the system.

- If your primary focus is system longevity: Understand that the nitrogen purge is more critical than your choice of fuel gas for ensuring a clean, reliable, and long-lasting HVAC system.

Ultimately, mastering the brazing process is about controlling both the heat you apply and the atmosphere inside the pipe.

Summary Table:

| Gas Type | Primary Function | Common Choice | Key Benefit |

|---|---|---|---|

| Fuel Gas | Provides heat for melting brazing filler metal | Oxygen-Acetylene | Highest flame temperature for fast, efficient work |

| Purge Gas | Protects the inside of the pipe from oxidation | Nitrogen (Dry) | Prevents scale formation that can destroy system components |

Ensure the longevity and performance of your HVAC systems with the right equipment and expertise. KINTEK specializes in providing high-quality lab and HVAC equipment, including reliable solutions for your brazing and system maintenance needs. Our expertise helps laboratories and technicians achieve precise, contamination-free results. Contact us today via our [#ContactForm] to discuss how we can support your specific HVAC and laboratory challenges.

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer

- High Performance Laboratory Freeze Dryer for Research and Development

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is cool grinding technology? Unlock Efficient Milling for Heat-Sensitive Materials

- Why are plate temperature uniformity and flatness important in a freeze dryer? Ensure Product Quality and Process Efficiency

- How are the shelves inside an Ultra Freezer designed to maintain temperature uniformity? Ensuring Sample Integrity with Compartmentalized Shelves

- Why are conventional preservation methods less suitable for biological products? The Critical Risk to Efficacy and Safety

- What is the standard time for sterilization? Optimize Your Process for Safety and Efficiency