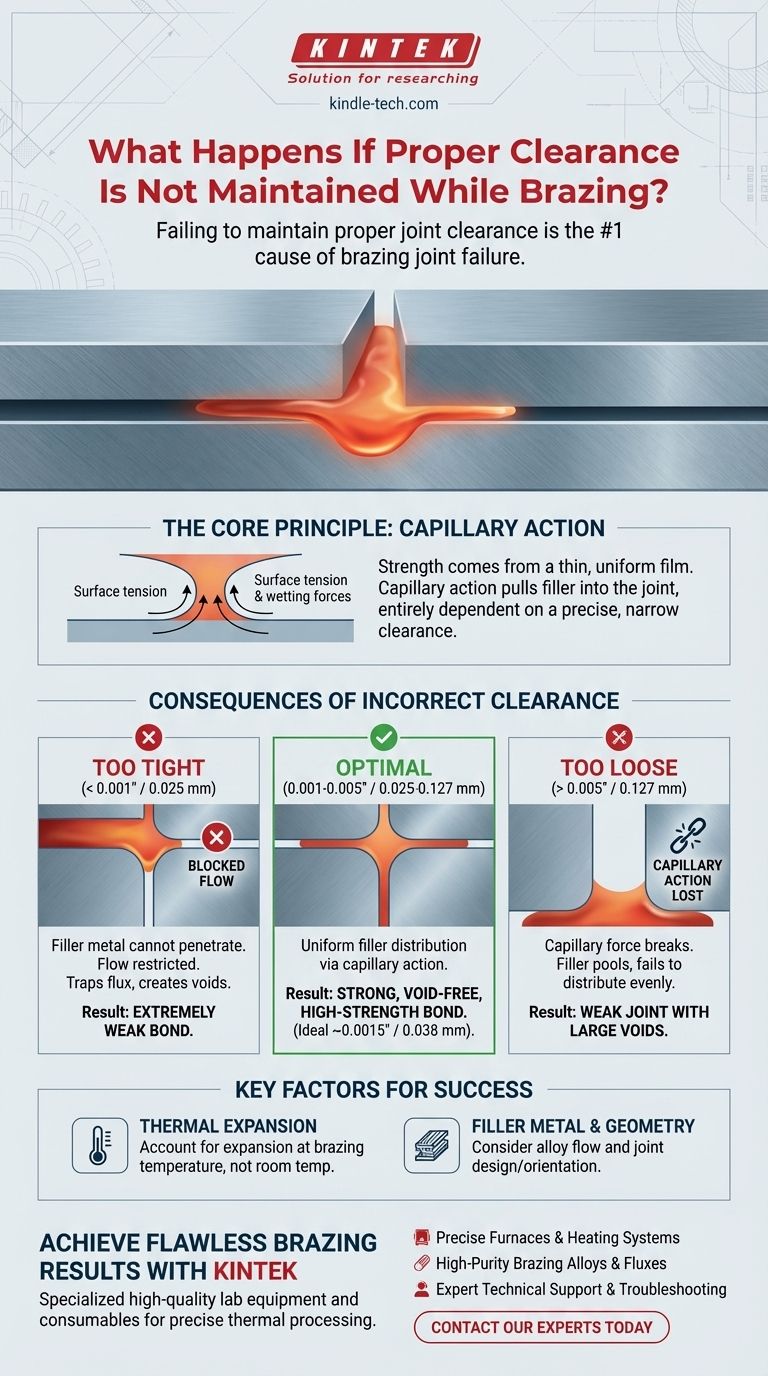

Failing to maintain proper joint clearance during brazing is the most common cause of joint failure. If the gap is too tight, the filler metal cannot flow into the joint, and if it's too wide, the capillary action needed to distribute the filler is lost, resulting in an incomplete and critically weak bond.

The core principle of brazing is that the strength of the joint comes from the filler metal forming a thin, uniform film between two base metal surfaces. This is only possible through capillary action, a force that is entirely dependent on maintaining a precise, narrow clearance between the parts.

The Critical Role of Capillary Action

To understand why clearance is paramount, you must first understand the force that makes brazing work.

What is Capillary Action?

Capillary action is the phenomenon where a liquid is drawn into a very narrow space, even against the force of gravity. The molten brazing filler metal behaves like this liquid.

This force is created by the combination of the filler metal's surface tension and its attraction to the surface of the base metals (a property called "wetting").

How Clearance Governs This Force

Capillary action is only effective within a very specific range of clearances. The gap must be wide enough to allow the molten alloy to flow, but narrow enough for the capillary force to be strong enough to pull it through the entire joint area.

A proper clearance ensures the filler metal is distributed completely and uniformly, creating a void-free, high-strength metallurgical bond upon cooling.

Consequences of Incorrect Clearance

Deviating from the optimal clearance range has immediate and predictable negative outcomes.

When the Gap is Too Tight

If the clearance is too narrow (e.g., less than 0.001 inches or 0.025 mm), the molten filler metal simply cannot penetrate the joint.

The flow will be restricted, often stopping at the outer edge. This can also trap flux inside the joint, creating voids and potential corrosion sites, leading to an extremely weak or non-existent bond.

When the Gap is Too Loose

If the clearance is too wide (e.g., greater than 0.005 inches or 0.127 mm), the force of capillary action is broken.

The filler metal will fail to distribute evenly and will tend to follow gravity or build up in large pools. The resulting joint will have large voids and will rely on the shear strength of the filler metal itself, which is significantly weaker than a properly brazed joint.

Determining the Optimal Clearance

While there is a general rule, several factors influence the ideal gap for a specific application.

The General Rule of Thumb

For most common brazing alloys, the ideal joint clearance at brazing temperature is between 0.001 and 0.005 inches (0.025 to 0.127 mm).

Many experienced technicians find that a clearance of 0.0015 inches (0.038 mm) provides the maximum joint strength for a wide range of applications.

Factors That Modify the Ideal Gap

The general rule is a starting point. You must also consider the specifics of your materials and joint design.

Different filler metals have different flow characteristics. More fluid alloys may require tighter clearances, while more sluggish alloys might need a slightly wider gap.

Critically, you must account for thermal expansion. The clearance must be correct at the brazing temperature, not at room temperature. When joining dissimilar metals, their different expansion rates can either close the gap or open it too wide during heating.

Common Pitfalls to Avoid

Understanding the theory is the first step. Avoiding these common mistakes is the next.

Mistaking Filler Metal for Strength

A common error is to think that a thicker layer of filler metal creates a stronger joint. The opposite is true. The strength of a brazed joint comes from the thin-film interaction between the filler and base metals. Any excess filler metal in a wide gap actively weakens the connection.

Forgetting About Thermal Expansion

Designing a joint with the perfect room-temperature clearance is useless if that clearance disappears or becomes excessive at 800°C. Always calculate the effects of thermal expansion, especially when joining materials like steel to copper or steel to carbide.

Ignoring Part Geometry

The orientation and length of the joint matter. For very long overlaps, a slightly larger clearance might be needed to ensure the alloy can penetrate the full distance before solidifying.

Making the Right Choice for Your Goal

Achieving the correct clearance is a function of careful design and preparation.

- If your primary focus is high-volume production: Design parts to be self-jigging with built-in clearances (e.g., shoulders or steps) and use pre-formed filler metal rings for consistency.

- If your primary focus is joining dissimilar metals: You must calculate the differential thermal expansion to determine the correct cold clearance that will result in the ideal hot clearance.

- If your primary focus is one-off repairs or prototypes: Use feeler gauges to verify clearances before heating. Aim for a snug "slip fit" between the two parts.

Ultimately, mastering joint clearance is the single most important factor in creating strong, reliable, and repeatable brazed joints.

Summary Table:

| Clearance Issue | Consequence | Resulting Joint Quality |

|---|---|---|

| Too Tight (< 0.001 in / 0.025 mm) | Filler metal cannot flow; flux trapped | Weak or non-existent bond; voids |

| Too Wide (> 0.005 in / 0.127 mm) | Capillary action lost; filler pools | Weak joint with large voids |

| Optimal (0.001-0.005 in / 0.025-0.127 mm) | Uniform filler distribution via capillary action | Strong, void-free, high-strength bond |

Achieve Flawless Brazing Results with KINTEK

Struggling with inconsistent brazed joints or unexpected failures? The root cause is often improper joint clearance. At KINTEK, we specialize in providing the high-quality lab equipment and consumables you need for precise thermal processing.

We understand that your laboratory's success depends on reliable, repeatable results. Whether you are working on high-volume production, joining dissimilar metals, or complex R&D projects, having the right tools and knowledge is critical.

Let us help you:

- Select the right furnaces and heating systems for precise temperature control.

- Source high-purity brazing alloys and fluxes optimized for your specific materials.

- Access expert technical support to troubleshoot joint design and process parameters.

Don't let joint clearance issues compromise your work. Contact our experts today for a consultation and ensure your brazing processes are built on a foundation of strength and reliability.

Visual Guide

Related Products

- Sample Support Body for Electrochemical Tests

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- What are the factors affecting sample size requirements? Master the Trade-Offs for Credible Research

- How should an electrode holder be cleaned as part of regular maintenance? Ensure Reliable Electrochemical Measurements

- What are the steps for post-experiment procedures after using the cell with a conventional aqueous solution? Ensure Accuracy and Reproducibility

- How should the PTFE electrode stand be adjusted to fit the electrolytic cell? Ensure Maximum Stability for Your Experiments