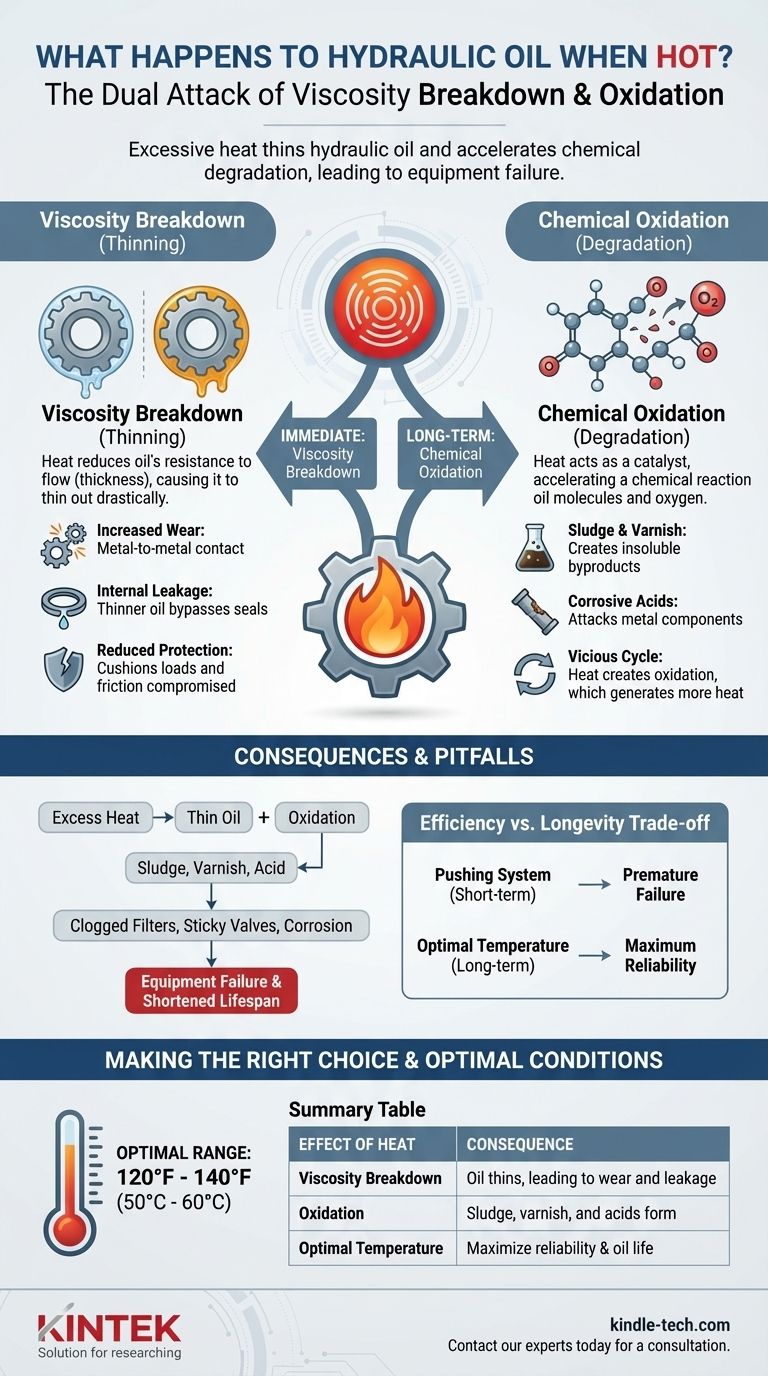

When hydraulic oil gets too hot, it becomes dangerously thin and begins to break down chemically. This dual attack significantly reduces its ability to lubricate and protect system components, leading directly to increased friction, accelerated wear, and a higher risk of premature equipment failure.

The core issue with hot hydraulic oil is not just the immediate thinning. It’s the start of a runaway chemical reaction called oxidation, which permanently degrades the oil, creates harmful sludge and varnish, and halves the oil's lifespan for every 18°F (10°C) increase above its optimal temperature.

The Immediate Physical Effect: Viscosity Breakdown

What is Viscosity?

Think of viscosity as the oil's "thickness" or its resistance to flow. A high-viscosity fluid like honey flows slowly, while a low-viscosity fluid like water flows easily.

In a hydraulic system, viscosity is the most critical property. It's what allows the oil to create a protective film between moving metal parts, preventing direct contact and wear.

How Heat Reduces Viscosity

As oil heats up, its molecules move faster and farther apart, reducing the internal friction that gives it thickness. This causes the oil to thin out, drastically lowering its viscosity.

The Consequences of Thin Oil

When oil becomes too thin, the lubricating film it creates can break down under pressure. This leads to several immediate problems:

- Increased Wear: Metal-to-metal contact occurs, accelerating wear on pumps, motors, and valves.

- Internal Leakage: Thinner oil bypasses seals inside components more easily, reducing system efficiency, speed, and power.

- Reduced Protection: The oil’s ability to cushion loads and protect against friction is severely compromised.

The Long-Term Chemical Attack: Oxidation

Understanding Oxidation

Oxidation is a chemical reaction between the oil’s base molecules and oxygen. Heat acts as a powerful catalyst, dramatically speeding up this destructive process. Contaminants like water and metal particles also accelerate it.

The Vicious Cycle of Heat

The danger of oxidation lies in a feedback loop. Heat accelerates oxidation, and oxidation is an exothermic process—meaning it generates its own heat.

This creates a vicious cycle where heat creates more oxidation, which in turn creates more heat, causing the oil to degrade at an exponential rate.

Byproducts of Degradation: Sludge and Varnish

As oxidation breaks down the oil, it forms insoluble byproducts. These manifest as sludge (a soft, tar-like substance) and varnish (a hard, sticky lacquer).

How Varnish and Sludge Harm a System

These contaminants are devastating to a hydraulic system. They clog filters, stick to valve spools, block small orifices, and coat internal surfaces.

A layer of varnish also acts as an insulator, preventing components from dissipating heat effectively and making the overheating problem even worse.

The Impact of Acid Formation

Oxidation also creates corrosive acids. These acids attack metal components from the inside, leading to corrosion and further contaminating the oil with metal particles. They also degrade seals and hoses, causing them to harden and crack.

Understanding the Trade-offs and Pitfalls

Efficiency vs. Longevity

Running a hydraulic system outside its optimal temperature range is a direct trade-off between short-term operation and long-term health. Pushing the system hard may get the job done, but the cost will be paid in premature component failure and drastically shortened oil life.

The Hidden Cost of Varnish

Varnish is a primary cause of "unexplained" hydraulic failures. A valve that sticks one day but works the next is often a symptom of varnish buildup. Ignoring it leads to unpredictable performance and eventual catastrophic failure.

Ignoring Temperature is Ignoring Health

Temperature is the single most important vital sign of a hydraulic system. An abnormally high temperature is never the root problem; it is always a symptom of an underlying issue, such as an inefficient component or an undersized heat exchanger.

Making the Right Choice for Your Goal

To prevent failures, it's crucial to monitor and control the system's operating temperature. The goal is to keep the oil within its ideal viscosity range, typically between 120°F and 140°F (50°C and 60°C).

- If your primary focus is maximum reliability and longevity: Prioritize maintaining the oil temperature within its optimal range through properly sized coolers and routine system maintenance.

- If you are troubleshooting poor performance or loss of power: Investigate system temperature immediately, as low viscosity from excess heat is a primary cause of internal leakage and reduced efficiency.

- If you are performing maintenance and find dark, sludgy oil: Treat this as a clear symptom of a chronic overheating problem that must be diagnosed and fixed, rather than simply changing the oil.

Managing heat is the most effective strategy for ensuring the long-term health, efficiency, and reliability of any hydraulic system.

Summary Table:

| Effect of Heat | Consequence |

|---|---|

| Viscosity Breakdown | Oil thins, leading to metal-on-metal wear and internal leakage. |

| Oxidation | Chemical degradation creates sludge, varnish, and corrosive acids. |

| Optimal Temperature | 120°F - 140°F (50°C - 60°C) for maximum reliability and oil life. |

Protect your hydraulic systems from the damaging effects of heat. KINTEK specializes in lab equipment and consumables, providing reliable solutions for monitoring and maintaining optimal operating conditions. Ensure your system's longevity and efficiency—contact our experts today for a consultation tailored to your laboratory's needs.

Visual Guide

Related Products

- Manual Lab Heat Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What temp is too hot for hydraulic oil? Avoid Costly System Damage with This Guide

- What are the uses of hydraulic press in food industry? Achieve Superior Separation & Preservation

- Purpose of Large-Tonnage Hydraulic Presses in Solid-State Battery Cathodes? Achieve 770 MPa for Maximum Densification

- What is the difference between hydraulic and mechanical power press? Choose the Right Press for Your Production Needs

- What are the functions of a cylindrical pelleting mold and a hydraulic press in LATP ceramics? Create High-Density Pellets

- What is the function of a laboratory hydraulic pressing device in U-bend SCC tests? Master Stress Corrosion Cracking

- Why is a laboratory hydraulic press essential for MEA fabrication? Ensure Precision in Hydrogen Compressors

- What is the pressed pellet technique for XRF? A Guide to Accurate Sample Preparation