In short, modern laboratory vacuum pumps are significantly quieter due to fundamental improvements in motor technology, the design of the pumping mechanism itself, and superior vibration isolation. Manufacturers now treat noise покупателями a critical design parameter, engineering quieter operation from the ground up rather than trying to muffle a loud design.

The core shift is from simply building a functional pump to designing a complete system optimized for the laboratory environment. Noise is no longer an accepted byproduct but a key performance metric इंजीनियरिंगd against, primarily by reducing friction, vibration, and air turbulence at their source.

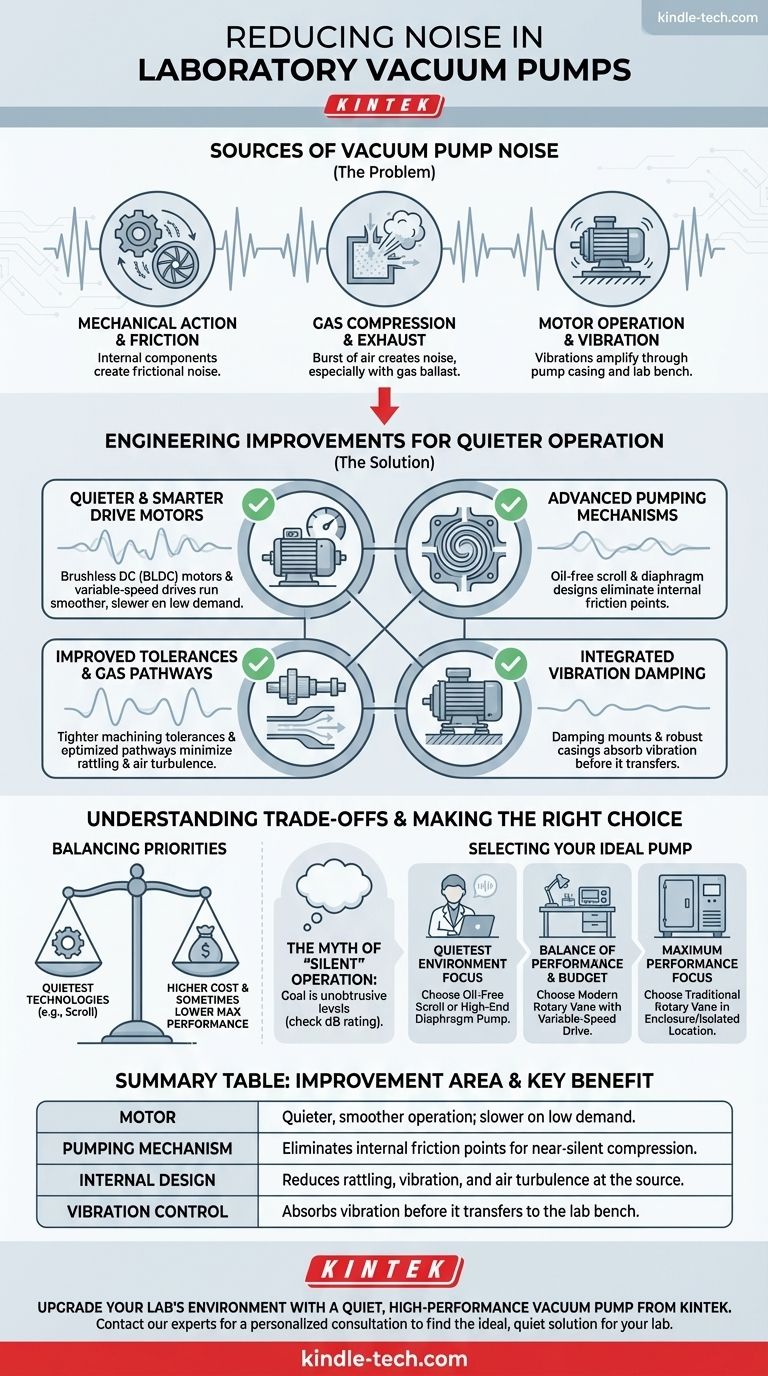

The Sources of Vacuum Pump Noise

To understand the improvements, we must first identify why traditional pumps are loud. The noise originates from three primary sources.

Mechanical Action and Friction

The internal components of the pump—such as the vanes sliding against the chamber wall in a rotary vane pump—create significant frictional noise. The motor, bearings, and gears all contribute to this mechanical sound signature.

Gas Compression and Exhaust

As the pump compresses the low-pressure gas from the vacuum chamber to atmospheric pressure, the process generates noise. The final burst of air from the exhaust port is often a major contributor, especially when using a gas ballast to handle vapors.

Motor Operation and Vibration

The pump's motor creates its own operational noise and, more importantly, vibrations. These vibrations travel through the pump's casing and into the lab bench or floor, which then acts as a large speaker, amplifying and radiating the noise throughout the room.

Key Engineering Improvements for Noise Reduction

Modern designs attack each source of noise with specific engineering solutions, leading to a dramatically quieter working environment.

Quieter and Smarter Drive Motors

Many newer pumps have abandoned traditional, noisy AC induction motors in favor of brushless DC (BLDC) motors. These are inherently quieter and smoother.

Furthermore, the integration of variable-speed drives allows the pump to run only as fast as necessary. During periods of low demand, the pump can slow down, significantly reducing noise, energy consumption, and mechanical wear.

Advanced Pumping Mechanisms

The very design of the pumping mechanism has evolved. While traditional rotary vane pumps are effective, their sliding-vane design is a source of friction and noise.

Newer, oil-free scroll pumps are a major leap forward in quiet operation. They use two interleaved spiral-shaped scrolls to compress gas without any internal friction points, making them exceptionally quiet and a popular choice for in-lab use. Multi-stage diaphragm pumps also offer a quieter, oil-free alternative for many applications.

Improved Tolerances and Gas Pathways

Modern manufacturing allows for much tighter machining tolerances on internal components. This precision fit reduces rattling, vibration, and inefficient gas flow, all of which contribute to noise. The internal pathways for gas have also been aerodynamically optimized to minimize turbulence as air is compressed and exhausted.

Integrated Vibration Damping

Manufacturers now build vibration control directly into the pump. This includes using advanced elastomeric feet, internal isolation mounts for the motor and pumping mechanism, and designing heavier, more robust casings that absorb and deaden vibration before it can escape.

Understanding the Trade-offs

While modern pumps are quieter, selecting one involves balancing competing priorities.

Cost vs. Quietness

The quietest technologies, like oil-free scroll pumps, typically have a higher upfront purchase price than traditional rotary vane pumps. You are paying a premium for the advanced engineering and improved work environment.

Performance vs. Noise

For some ultra-high vacuum applications, the most powerful and fastest-pumping technologies can still be the loudest. However, many modern pumps with variable-speed drives allow you to balance this, running at full power for rapid pump-down and then at a slower, quieter speed to maintain the vacuum.

The Myth of "Silent" Operation

No mechanical vacuum pump is truly silent. The goal of modern design is to reduce the noise to a level that is unobtrusive and comfortable, often below the level of a normal conversation. Always check the decibel (dB) rating in the manufacturer's specifications.

Making the Right Choice for Your Lab

Your ideal pump depends on where and how you will use it.

- If your primary focus is the quietest possible environment: Choose an oil-free scroll pump or a high-end, multi-stage diaphragm pump, especially if the pump will be located on the benchtop next to personnel.

- If your primary focus is a balance of performance and budget: A modern rotary vane pump featuring a variable-speed drive and specified as a "low-noise" model is an excellent choice.

- If your primary focus is maximum performance for a dedicated system: A traditional, high-capacity rotary vane pump may be necessary, but consider placing it in a dedicated enclosure, a separate room, or on the floor to minimize benchtop vibration.

By understanding the technology behind noise reduction, you can select a vacuum pump that meets your performance needs while fostering a quieter and more productive laboratory.

Summary Table:

| Improvement Area | Key Technology | Noise Reduction Benefit |

|---|---|---|

| Motor | Brushless DC (BLDC) with Variable-Speed Drive | Quieter, smoother operation; runs slower when demand is low |

| Pumping Mechanism | Oil-Free Scroll or Diaphragm Design | Eliminates internal friction points for near-silent compression |

| Internal Design | Precision Machining & Optimized Gas Pathways | Reduces rattling, vibration, and air turbulence at the source |

| Vibration Control | Integrated Damping Mounts & Heavy-Duty Casings | Absorbs vibration before it transfers to the lab bench |

Upgrade your lab's environment with a quiet, high-performance vacuum pump from KINTEK.

Excessive noise can disrupt concentration and reduce productivity. KINTEK specializes in laboratory equipment and consumables, offering a range of advanced vacuum pumps engineered for quiet operation without compromising on performance. Whether you need a benchtop scroll pump for a shared workspace or a powerful rotary vane pump with variable-speed control, we have the solution to meet your specific application and noise-level requirements.

Let our experts help you select the ideal pump for a quieter, more efficient lab. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why are agate grinding jars preferred over metal jars for LLZO powders? Ensure Ultra-High Purity in Milling

- Why are cemented carbide balls selected as the grinding media? Optimize Graphene-Reinforced Alumina Ceramics

- What is the purpose of a gas bubbler system for BZY20 ceramics? Unlocking Proton Conduction Performance

- What is the maximum pressure for a vacuum pump? Understanding Ultimate Vacuum for Your Lab Needs

- What is a furnace retort? Your Guide to Precision Atmosphere Control for Heat Treatment

- What functions do high-temperature stainless steel fixtures perform in TLP bonding? Ensure Joint Integrity

- What is the primary function of laboratory stirring equipment in the preparation of compost leachate? Optimize Extraction

- Why is high-precision stirring equipment required for co-precipitation? Ensure Nanoscale Catalyst Uniformity