A 134 autoclave cycle refers to a high-temperature steam sterilization process that operates at 134°C (273°F). It is a rapid and highly effective method used to sterilize heat-resistant materials, most notably metal surgical and dental instruments. This higher temperature allows for shorter cycle times compared to the other common standard of 121°C.

The choice between different autoclave temperatures is a critical decision based on a trade-off between speed and material sensitivity. The 134°C cycle is the standard for fast, high-performance sterilization of durable instruments, while other temperatures are required for more delicate loads.

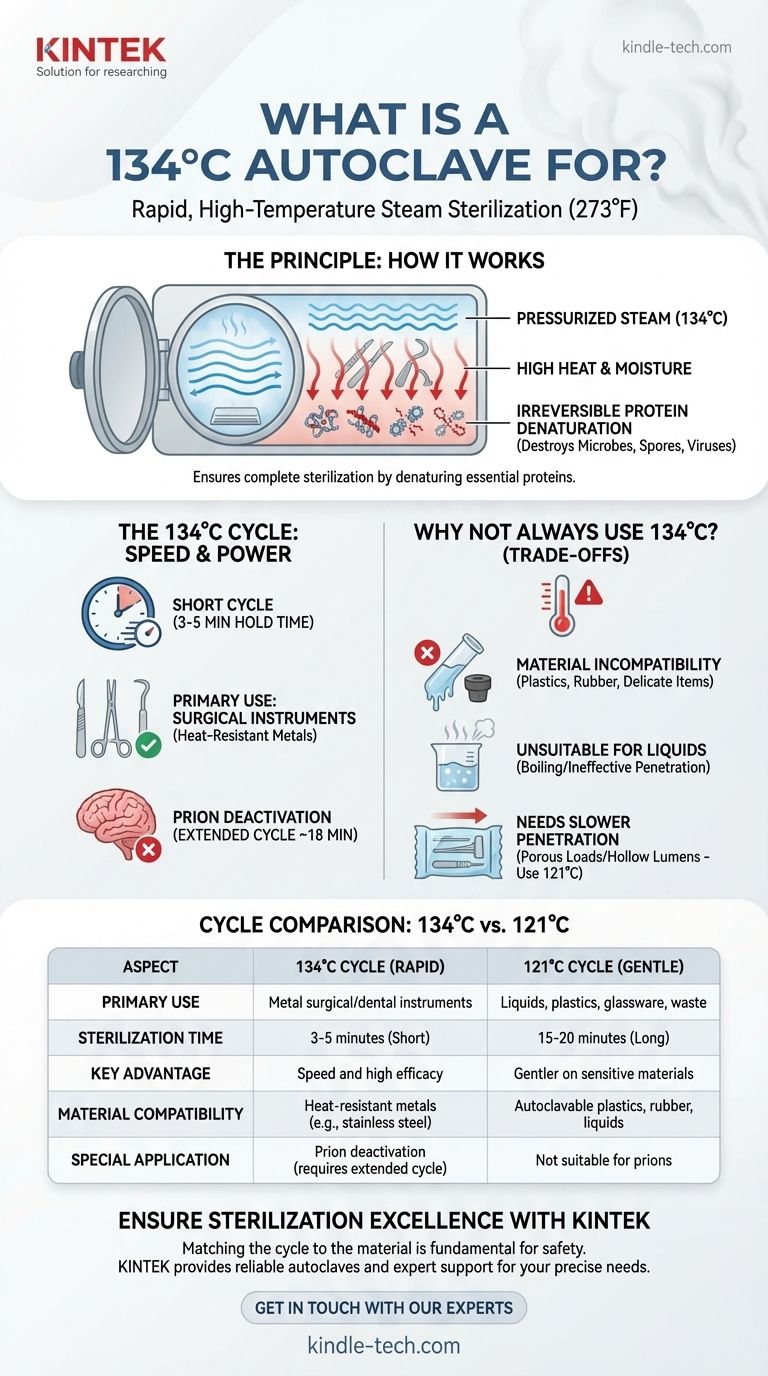

The Principle of Steam Sterilization

How an Autoclave Works

An autoclave is essentially a highly sophisticated pressure chamber. It uses pressurized steam to elevate the temperature of the items inside to a level that guarantees sterilization.

This combination of high heat and moisture is exceptionally effective at destroying all forms of microbial life, including resilient bacterial spores, viruses, and fungi. It achieves this by irreversibly denaturing the proteins essential for these organisms to live.

Why Temperature Is a Key Variable

The temperature of the steam directly impacts the time required to achieve sterility. Higher temperatures can destroy microorganisms much faster.

This relationship gives rise to standardized cycles, with 134°C and 121°C being the most common in medical, laboratory, and pharmaceutical settings. Each is designed for specific applications.

The 134°C Cycle: Speed and Power

Primary Use: Surgical Instruments

The 134°C cycle is the workhorse of hospital central sterile supply departments (CSSDs) and surgical centers. It is primarily used for hard, non-porous goods like stainless steel surgical tools, forceps, and retractors.

Its main advantage is speed. A typical 134°C cycle might have a sterilization holding time of only 3 to 5 minutes, allowing for rapid turnaround of critical equipment between procedures.

Effectiveness Against Prions

A critical application for the 134°C cycle is the deactivation of prions. Prions are infectious proteins that cause fatal neurodegenerative conditions like Creutzfeldt-Jakob Disease (CJD).

Standard disinfection methods are ineffective against prions. An extended 134°C cycle (e.g., 18 minutes or longer) is the required protocol for sterilizing instruments that have been in contact with high-risk tissue.

Understanding the Trade-offs: Why Not Always Use 134°C?

Material Incompatibility

The intense heat of a 134°C cycle can damage or destroy many common laboratory and medical materials.

Items such as autoclavable plastics, certain types of rubber, and delicate instruments would warp, melt, or degrade. These materials require the gentler, longer 121°C cycle.

Unsuitability for Liquids

Attempting to sterilize liquids (like culture media or saline solutions) at 134°C is both ineffective and dangerous.

The high temperature can cause liquids to boil over aggressively, leading to loss of volume and potential damage to the autoclave. Furthermore, the short cycle time does not allow for the slow, even heat penetration required to sterilize a liquid volume completely.

The Need for Slower Penetration

The 134°C cycle is designed for surface sterilization of hard goods where steam can make immediate contact.

For complex items with hollow lumens or porous loads like wrapped instrument kits or biohazardous waste, the lower 121°C temperature and longer cycle time are necessary to ensure steam fully penetrates the entire load.

Selecting the Right Sterilization Cycle

Choosing the correct autoclave program is not optional; it is essential for safety and equipment preservation.

- If your primary focus is the rapid turnaround of durable, non-porous metal instruments: The 134°C cycle is the industry standard for its unmatched speed and efficacy.

- If your primary focus is sterilizing liquids, plastics, glassware, or most biohazardous waste: The slower, lower-temperature 121°C cycle is required to ensure complete sterilization without causing damage.

- If your primary focus is eliminating the risk of prion contamination: An extended 134°C cycle is the only validated and accepted protocol for ensuring patient safety.

Ultimately, matching the sterilization cycle to the material being processed is fundamental to any effective safety protocol.

Summary Table:

| Aspect | 134°C Cycle | 121°C Cycle |

|---|---|---|

| Primary Use | Metal surgical/dental instruments | Liquids, plastics, glassware, waste |

| Sterilization Time | 3-5 minutes (short) | 15-20 minutes (long) |

| Key Advantage | Speed and high efficacy | Gentler on sensitive materials |

| Material Compatibility | Heat-resistant metals (e.g., stainless steel) | Autoclavable plastics, rubber, liquids |

| Special Application | Prion deactivation (requires extended cycle) | Not suitable for prions |

Ensure Sterilization Excellence with KINTEK

Choosing the right autoclave cycle is critical for safety, efficiency, and protecting your valuable equipment. Whether you need the rapid, high-power sterilization of a 134°C cycle for surgical instruments or the gentle, penetrating action of a 121°C cycle for liquids and plastics, KINTEK has the solution.

We provide reliable autoclaves and expert support to meet the precise needs of laboratories, hospitals, and research facilities.

Contact us today to find the perfect sterilization equipment for your requirements and ensure your protocols are both effective and safe.

Visual Guide

Related Products

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What role does a laboratory autoclave play in the separation of lignin? High-Purity Extraction for Biomass Research

- Are there any specific types of contamination that an autoclave cannot remove? Understanding the Limits of Steam

- What extreme conditions does a laboratory autoclave simulate? Testing Wear Resistance of Nuclear Fuel Cladding