At its core, a 20-ton hydraulic press is a machine that multiplies force. It is most commonly used in workshops and laboratories for assembling, dismantling, and shaping materials with a level of force that is impossible to achieve by hand. Key applications include pressing bearings into place, bending metal, straightening parts, and preparing material samples for scientific analysis.

While the "20-ton" figure suggests massive industrial power, its true value lies in providing immense, controlled force in a relatively compact machine. It bridges the gap between manual tools and large-scale factory equipment, making it a cornerstone of professional workshops and labs.

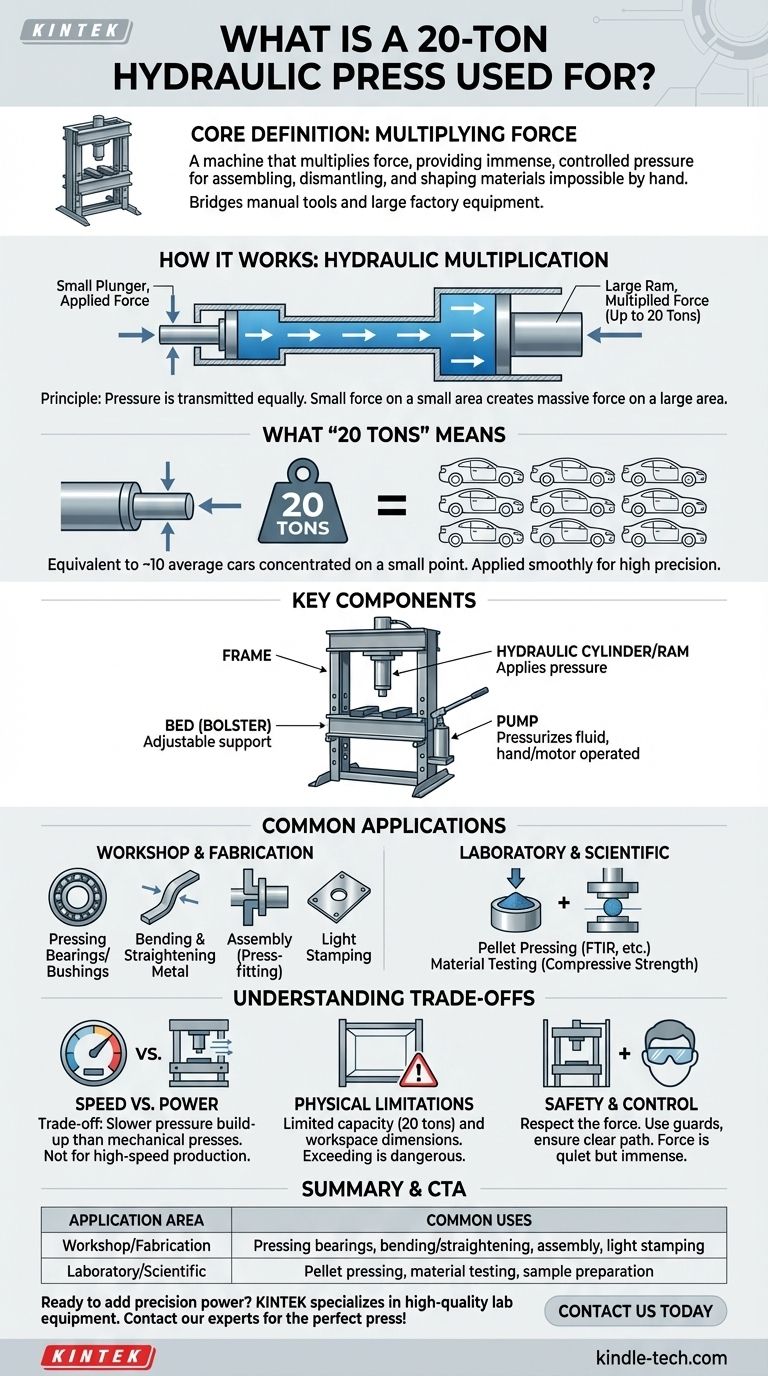

How a Hydraulic Press Achieves 20 Tons of Force

The power of a hydraulic press comes not from a complex motor, but from a fundamental principle of fluid dynamics.

The Principle of Hydraulic Multiplication

A hydraulic press uses two interconnected cylinders of different sizes, both filled with hydraulic fluid. One cylinder is small (the plunger) and the other is large (the ram).

When a small amount of force is applied to the plunger, it creates pressure in the fluid. This pressure is transmitted equally throughout the fluid, acting on the much larger surface area of the ram.

This difference in area multiplies the initial force exponentially. A small effort on the plunger results in a massive force—in this case, up to 20 tons—exerted by the ram.

What "20 Tons" Actually Means

The 20-ton rating is the maximum output force the press can generate. This is equivalent to the weight of about 10 average-sized cars concentrated on the small contact point of the ram.

This force is applied smoothly and consistently, unlike the jarring impact of a hammer or a mechanical press, allowing for high precision.

Key Components of the Press

A typical 20-ton press has a simple and robust design.

- Frame: The main structure that holds all components together and withstands the immense forces during operation.

- Bed (or Bolster): The adjustable flat surface that supports the workpiece being pressed.

- Hydraulic Cylinder/Ram: The component that moves down to apply pressure to the workpiece.

- Pump: The mechanism, often operated by a hand lever or a small motor, that pressurizes the hydraulic fluid.

Common Applications for a 20-Ton Press

The versatility of a 20-ton press makes it valuable in a variety of professional settings.

Workshop and Fabrication Tasks

In an automotive or metalworking shop, a 20-ton press is an indispensable tool for jobs that require significant, controlled force.

- Pressing Bearings and Bushings: This is the most common use. It allows for the smooth installation or removal of press-fit bearings and bushings without damaging the component or housing.

- Bending and Straightening Metal: It can be used with dies to create precise bends in metal plates or bars, or to straighten parts that have been bent or warped.

- Assembly: It is ideal for press-fitting parts together, such as pins, shafts, and gears, creating a strong mechanical bond.

- Stamping: With the right attachments, it can be used for light-duty stamping or punching holes in sheet metal.

Laboratory and Scientific Use

The precise and consistent pressure of a hydraulic press is critical for sample preparation in scientific analysis.

- Pellet Pressing: It is frequently used to press powdered samples into solid pellets or thin films. This is a standard procedure for techniques like FTIR spectroscopy, where a sample must be prepared in a KBr (potassium bromide) pellet.

- Material Testing: The press can be used to perform compressive strength tests on materials, determining how they behave under a specific load.

Understanding the Trade-offs

While powerful, a hydraulic press is not the right tool for every situation. Understanding its limitations is key to using it effectively.

Speed vs. Power

The primary trade-off for a hydraulic press is speed. The process of building hydraulic pressure is inherently slower than the direct action of a mechanical press. This makes it unsuitable for high-volume, rapid-fire production lines.

Physical and Force Limitations

A 20-ton press is extremely powerful for its size but is not meant for heavy industrial forging. Its capacity is limited to 20 tons, and exceeding this can damage the machine or create a hazardous failure. The physical size of the frame and bed also limits the dimensions of the workpiece you can handle.

The Need for Safety and Control

Any machine that generates this much force demands respect. Built-in overload protection is a common safety feature, but proper operation is crucial. The force is quiet and can be deceptive, making it essential to use proper guards and ensure no body parts are ever in the path of the ram.

Making the Right Choice for Your Goal

To determine if a 20-ton press is the correct tool, consider your primary objective.

- If your primary focus is automotive repair or small-scale fabrication: A 20-ton press is an essential, multi-purpose tool for bearings, bushings, and bending moderate-sized components.

- If your primary focus is laboratory analysis: This press is the standard for creating high-quality, consistent sample pellets for spectroscopic and material testing applications.

- If your primary focus is high-volume manufacturing: You will likely find a 20-ton hydraulic press too slow and should investigate faster mechanical presses or more automated hydraulic systems.

Ultimately, a 20-ton hydraulic press empowers you to apply precise and immense force, transforming difficult manual tasks into controlled, repeatable processes.

Summary Table:

| Application Area | Common Uses |

|---|---|

| Workshop/Fabrication | Pressing bearings & bushings, bending/straightening metal, assembly, light stamping |

| Laboratory/Scientific | Pellet pressing for FTIR spectroscopy, material testing, sample preparation |

Ready to add precision power to your workshop or lab? A 20-ton hydraulic press is the cornerstone for tasks requiring controlled, immense force—from pressing bearings to preparing perfect samples for analysis. At KINTEK, we specialize in high-quality lab equipment and consumables designed to meet the rigorous demands of professionals. Let us help you find the perfect press for your specific needs. Contact our experts today to discuss your application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is something a hydraulic press can't break? The Physics of Force, Pressure, and Material Limits

- Can a diamond break under a hydraulic press? Uncover the Truth About Diamond's Brittleness

- How do laboratory hydraulic presses and molds ensure accuracy in high-strength gypsum concrete testing?

- What are the two methods of preparation of IR sample? A Guide to KBr Pellets and Nujol Mulls

- What is the function of a laboratory hydraulic press and a 15 mm circular mold? Create Dense Oxygen Membrane Green Bodies

- What is the role of sintering in powder metallurgy? Transforming Powder into Durable Metal Parts

- What precautions should be taken during IR spectroscopy? Master Sample Prep for Accurate Results

- Press forging vs. hammer forging: Which is right for your metal forming needs?