In essence, a burnout oven is a high-temperature furnace designed for a single, critical purpose: to melt and incinerate a pattern (typically made of wax or 3D-printed resin) out of a ceramic mold. This process, known as "burnout," leaves behind a hollow, perfectly clean cavity into which molten metal can be poured, a foundational step in investment casting for jewelry, dental, and industrial applications.

A burnout oven is not merely a heater; it is a precision instrument that executes a carefully timed, multi-stage temperature program. Its primary function is to create a flawless mold cavity by completely removing the original pattern without damaging the fragile mold shell.

The Role of the Burnout Oven in Investment Casting

The burnout process is the heart of investment casting, also known as the "lost-wax" process. The oven's performance directly determines the success or failure of the final cast part.

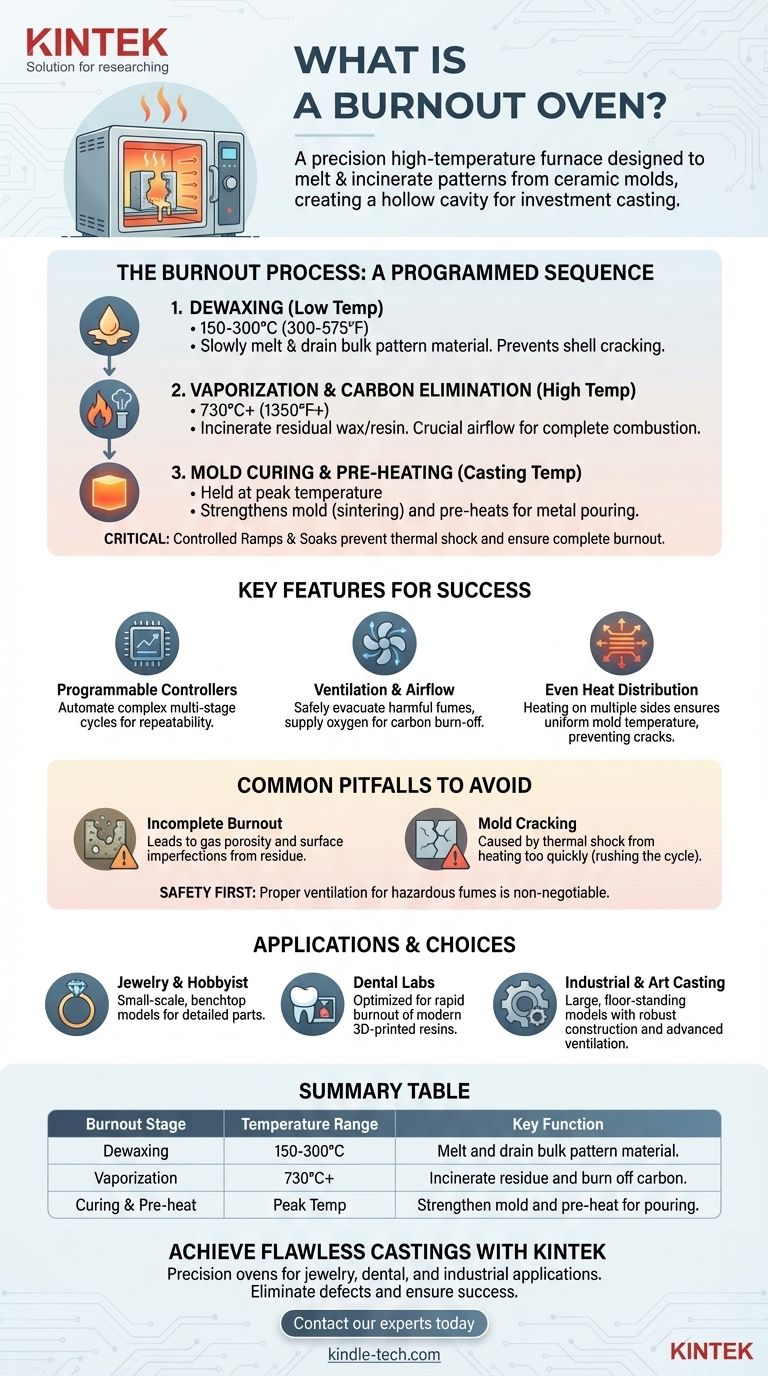

The "Burnout" Process Explained

A burnout cycle is not a simple, single-temperature bake. It is a programmed sequence of heating stages, often lasting 8 to 16 hours, designed to accomplish three distinct goals.

-

Stage 1: Dewaxing (Low Temperature) The cycle begins at a low temperature (around 150-300°C / 300-575°F). During this stage, the bulk of the pattern material melts and drains from the mold. This must be done slowly to prevent the expanding wax from cracking the mold shell.

-

Stage 2: Vaporization & Carbon Elimination (High Temperature) The temperature is then ramped up significantly (to 730°C / 1350°F or higher). This stage incinerates any residual wax or resin and, crucially, burns off the carbon residue left on the mold walls. Proper airflow is vital here to provide the oxygen needed for complete combustion.

-

Stage 3: Mold Curing & Pre-heating (Casting Temperature) Finally, the oven holds the mold at its peak temperature. This step fully cures and strengthens the ceramic investment material (a process called sintering). It also pre-heats the mold to the correct temperature for receiving molten metal, which prevents thermal shock and ensures the metal flows freely into the finest details.

Why Controlled Ramps and Soaks are Critical

The oven's controller manages the ramps (the rate of temperature change) and soaks (the time spent holding at a specific temperature).

- Ramps prevent thermal shock. If a mold heats up too quickly, different parts expand at different rates, causing cracks that will ruin the final casting.

- Soaks ensure each stage of the process is fully completed. A soak at the dewaxing temperature ensures most of the wax has drained, while a long soak at the peak temperature guarantees all carbon residue is gone and the mold is fully cured.

Understanding the Key Features

Modern burnout ovens are defined by their ability to precisely control the entire burnout cycle, ensuring repeatability and high success rates.

Programmable Controllers

The controller is the brain of the oven. It allows the user to program, save, and execute complex multi-stage burnout cycles. This programmability is the single most important feature, as it automates the long and delicate process.

Ventilation and Airflow

Proper ventilation is non-negotiable. It serves two purposes: safely evacuating the harmful fumes produced by melting wax or resin, and pulling fresh oxygen into the chamber. Without sufficient oxygen, the carbon residue will not burn off, leading to a contaminated mold and a failed casting.

Even Heat Distribution

High-quality ovens have heating elements on multiple sides of the chamber. This ensures the entire mold, regardless of its position, heats at a uniform rate. Uneven heating is a primary cause of mold cracking.

Common Pitfalls to Avoid

The burnout process is unforgiving. Misunderstanding the oven's function can lead to costly and time-consuming failures.

Incomplete Burnout

This is the most frequent failure. If the cycle is too short or lacks sufficient oxygen, residual pattern material or carbon will remain in the mold. When molten metal is poured in, this residue can cause gas porosity, surface imperfections, and incomplete castings.

Mold Cracking

Cracking is almost always caused by thermal shock—heating the mold too quickly. Using a pre-set, tested program with slow, controlled ramps is the best way to prevent this catastrophic failure.

The False Economy of Speed

It can be tempting to shorten a burnout cycle to save time. This is a false economy. A single failed casting, especially with precious metals, will cost far more in wasted material and labor than the few hours saved by rushing the burnout.

Ventilation and Safety

The fumes generated during burnout are hazardous. The oven must be located in a well-ventilated area, preferably under a dedicated exhaust hood. This is a critical safety requirement, not an optional extra.

Making the Right Choice for Your Application

Selecting an oven depends entirely on your specific materials, scale, and precision requirements.

- If your primary focus is hobbyist work or small-scale jewelry: A reliable benchtop model with a multi-stage programmable controller is your best investment. Focus on capacity that matches your typical flask size.

- If your primary focus is a dental laboratory: Choose an oven specifically designed for the rapid burnout of modern 3D-printed resins, which often require different burnout schedules and better ventilation than traditional wax.

- If your primary focus is industrial or large-scale art casting: Your needs will point toward larger, floor-standing models with robust construction, advanced ventilation systems (sometimes including an afterburner to eliminate fumes), and highly precise controllers.

Ultimately, the burnout oven is the silent partner in creating a perfect casting, enabling the entire process through its precise and patient control of temperature over time.

Summary Table:

| Burnout Stage | Temperature Range | Key Function |

|---|---|---|

| Dewaxing | 150-300°C (300-575°F) | Melt and drain bulk pattern material without cracking the mold. |

| Vaporization & Carbon Elimination | 730°C+ (1350°F+) | Incinerate residue and burn off carbon with proper airflow. |

| Mold Curing & Pre-heating | Held at peak temperature | Strengthen the mold and pre-heat for molten metal pouring. |

Achieve flawless castings with a burnout oven tailored to your needs. Whether you're in jewelry making, dental labs, or industrial casting, KINTEK's precision ovens deliver controlled heating, even heat distribution, and robust ventilation to eliminate mold defects and ensure casting success. Contact our experts today to find the perfect solution for your lab!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is the difference between composite and ceramic restoration? Choosing the Right Material for Your Smile

- What is a dental ceramic furnace? A Precision Oven for High-Strength, Aesthetic Restorations

- What is a dental burnout furnace? Achieve Precision in Every Dental Restoration

- Which is cheaper porcelain or ceramic crown? A Practical Guide to Dental Crown Costs & Materials

- What is the disadvantage of ceramic for implant? Understanding the Risk of Fracture and Long-Term Durability

- Is ceramic the same as porcelain teeth? A Guide to Choosing the Right Dental Material

- What is a crucial factor to consider when selecting a Dental Press Furnace? Material Compatibility is Key

- Which crown is better porcelain or ceramic? Choose the Right Material for Your Dental Needs