At its core, a filter press is a batch-processing machine designed for high-efficiency liquid-solid separation. It functions by pumping a slurry (a mixture of liquids and solids) into a series of chambers and applying immense pressure to squeeze the liquid out through a filter medium, leaving behind a dense, dewatered solid cake. This makes it an indispensable tool in industries ranging from wastewater treatment and mining to chemical manufacturing and food processing.

A filter press should not be viewed as a simple strainer, but as a complete dewatering system. Its effectiveness comes from using hydraulic pressure to compact solids into a dry, easily managed form while producing a clear liquid filtrate, making it one of the most powerful tools for liquid-solid separation.

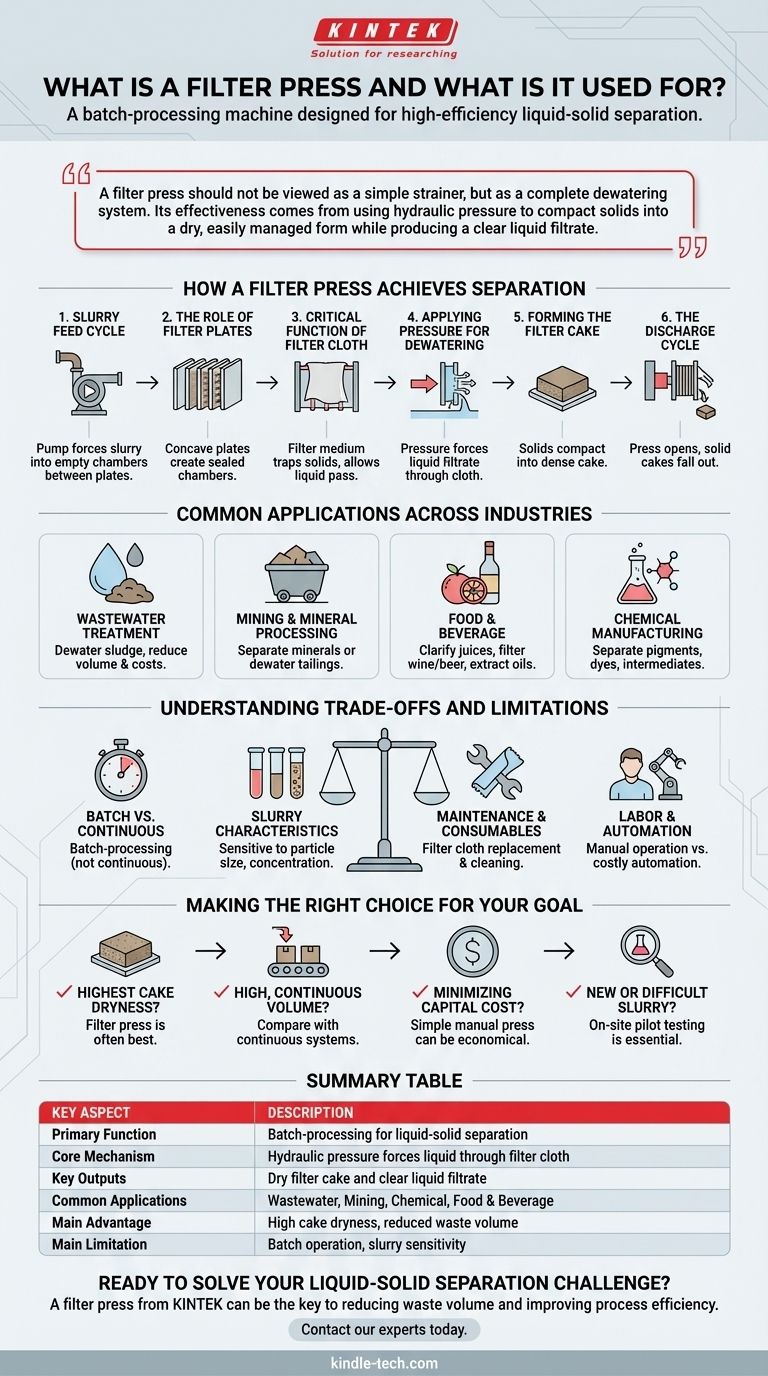

How a Filter Press Achieves Separation

A filter press operates in a repeating sequence known as a batch cycle. Understanding this cycle is key to understanding the machine's function.

The Slurry Feed Cycle

The process begins with the filter press in a closed and clamped position. A powerful pump forces the slurry into the empty chambers between the filter plates.

The Role of Filter Plates

The filter plates form the backbone of the machine. They are concave on both sides, and when pressed together, they create a series of sealed chambers that hold the slurry.

The Critical Function of Filter Cloth

A filter cloth is draped over each filter plate. This cloth is the actual filter medium. Its weave is designed to trap solid particles while allowing the liquid to pass through.

Applying Pressure for Dewatering

As the pump fills the chambers with slurry, pressure builds. This pressure forces the liquid component of the slurry through the filter cloth, out of the press via internal ports, and into a collection trough as a clear liquid called filtrate.

Forming the Filter Cake

The solids are trapped by the cloth and accumulate inside the chambers. As more liquid is forced out, the solids become increasingly compacted, forming a dense, semi-solid material known as a filter cake.

The Discharge Cycle

Once the chambers are full of solids and the flow of filtrate has nearly stopped, the slurry feed pump is shut off. A hydraulic ram retracts, opening the press and separating the plates. The solid filter cakes then fall from between the plates onto a conveyor or into a hopper for disposal or further processing.

Common Applications Across Industries

The ability to produce a very dry solid cake and a clear filtrate makes the filter press essential in many sectors.

Wastewater Treatment

Municipal and industrial wastewater plants use filter presses to dewater sludge. This drastically reduces the volume of the waste, lowering transportation and disposal costs.

Mining and Mineral Processing

In mining, filter presses separate valuable minerals from rock slurry or dewater mine tailings (waste material) to make them more stable and safer for storage.

Food and Beverage

The technology is used to clarify fruit juices, filter wine and beer, and extract edible oils like palm or olive oil, ensuring product purity and maximizing yield.

Chemical Manufacturing

Filter presses are used to separate solid products, such as pigments, dyes, and pharmaceutical intermediates, from their liquid process streams.

Understanding the Trade-offs and Limitations

While powerful, the filter press is not the right solution for every scenario. Acknowledging its operational trade-offs is crucial for proper application.

Batch vs. Continuous Operation

The filter press is a batch-processing machine. It must complete a full cycle (fill, press, discharge) before starting the next one. This can create a bottleneck in processes that require a continuous, uninterrupted flow.

Dependence on Slurry Characteristics

The machine's performance is highly sensitive to the nature of the slurry. Particle size, solids concentration, and the compressibility of the solids all impact filtration speed and final cake dryness. Some fine or gelatinous slurries can blind the filter cloths and are not suitable for this technology.

Maintenance and Consumables

Filter cloths are a consumable item. They require regular cleaning to maintain performance and must eventually be replaced. The cost and downtime associated with cloth replacement are an inherent operational expense.

Labor and Automation

Basic, manual filter presses require an operator to physically separate the plates and ensure the cake discharges properly. While fully automated systems exist to handle this, they come at a significantly higher capital cost.

Making the Right Choice for Your Goal

Selecting the correct dewatering technology requires a clear understanding of your primary operational driver.

- If your primary focus is achieving the highest possible cake dryness: A filter press is often the best choice, as the high pressures it generates can remove more liquid than many other technologies.

- If your primary focus is processing a very high, continuous volume: You should compare the batch nature of a filter press against continuous systems like a belt press or centrifuge to see which best fits your production line.

- If your primary focus is minimizing initial capital cost: A simple, manual filter press can be a highly effective and economical solution, provided you account for the associated labor requirements.

- If you are dealing with a new or difficult-to-filter slurry: On-site pilot testing with a small-scale press is essential to confirm its suitability and determine the optimal cloth type and operating parameters.

By understanding the filter press as a system of pressure, structure, and media, you can harness its power to solve your specific separation challenge.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Batch-processing machine for liquid-solid separation |

| Core Mechanism | Uses hydraulic pressure to force liquid through a filter cloth, leaving a solid 'cake' |

| Key Outputs | Dry filter cake and clear liquid filtrate |

| Common Applications | Wastewater treatment, mining, chemical manufacturing, food & beverage processing |

| Main Advantage | Achieves very high cake dryness, reducing waste volume and disposal costs |

| Main Limitation | Batch operation (not continuous); performance depends on slurry characteristics |

Ready to solve your liquid-solid separation challenge?

A filter press from KINTEK can be the key to reducing waste volume, lowering disposal costs, and improving process efficiency in your laboratory or production facility. Our expertise in lab equipment and consumables ensures you get the right solution for your specific needs, whether for wastewater sludge, mineral processing, or product purification.

Contact our experts today to discuss your application and discover how KINTEK's filtration solutions can deliver a drier cake and a clearer filtrate for your operation.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What refrigeration technologies are used in modern ULT freezers? Cascade vs. Stirling Cycle Explained

- What is the flash sintering process? Revolutionize Your Materials Processing in Seconds

- What is sintering in ceramic? The High-Temperature Process for Creating Dense, Strong Materials

- What is thin film deposition in semiconductors? Build the Core of Modern Electronics

- What is the temperature of sintering process? A Guide to Optimizing Your Thermal Treatment

- What is ion beam sputtering techniques? A Guide to High-Precision Thin Film Deposition

- What is the process of debinding? A Guide to Safe, Effective Binder Removal

- What are the two types of hot air ovens? Choose the Right Air Circulation for Your Lab