At its core, a filter press is a highly effective machine for separating solids from liquids. It works by pumping a slurry (a semi-liquid mixture) into a series of chambers and applying pressure, which forces the liquid out through a filter medium, leaving the dewatered solids behind.

A filter press is a batch-operated piece of equipment that dewaters slurries to produce a very dry solid cake and a clear liquid filtrate. Its reliability and efficiency make it a foundational technology in industries ranging from mining to wastewater treatment.

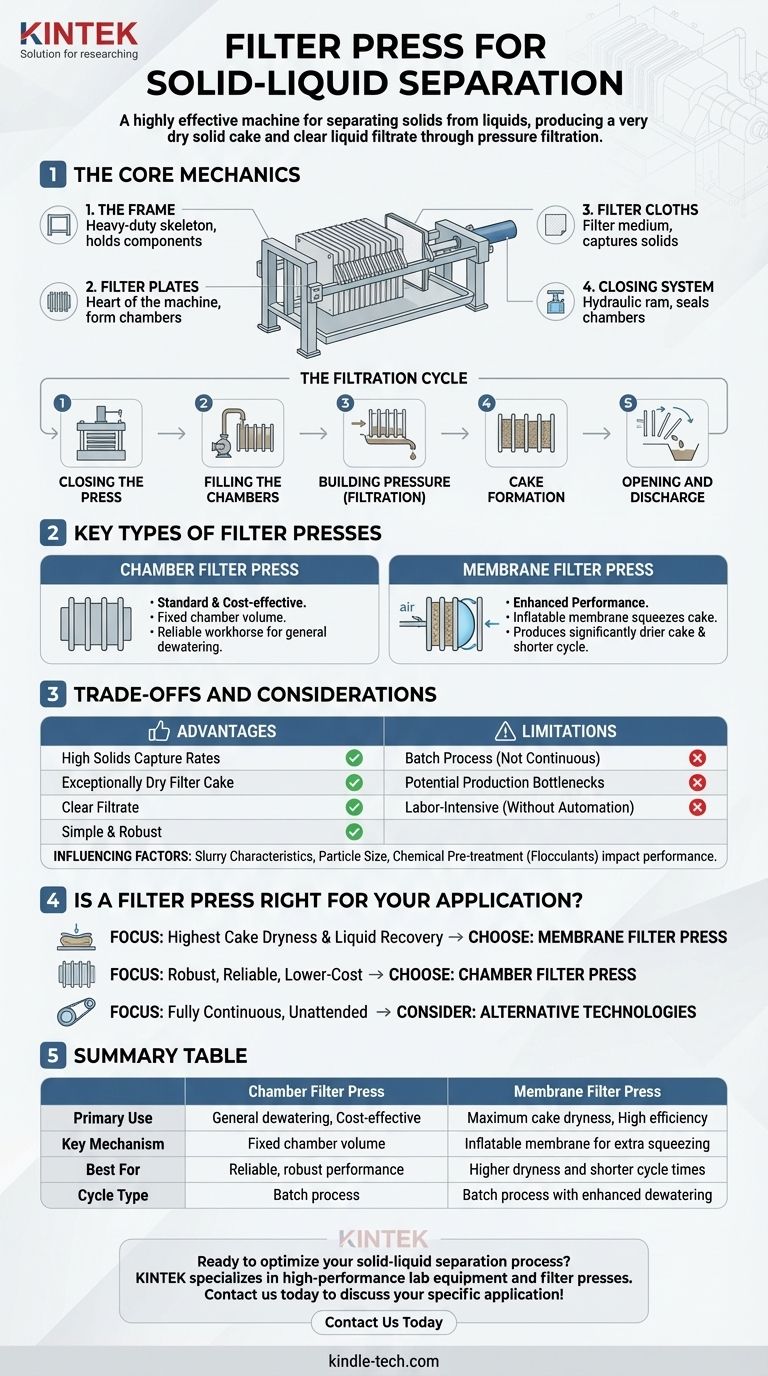

The Core Mechanics of a Filter Press

To understand how a filter press achieves such effective separation, it's essential to look at its components and the operational cycle. It operates on a simple principle: pressure filtration.

The Key Components

A filter press consists of four main parts working in concert.

- The Frame: This is the heavy-duty skeleton that holds everything together under immense pressure. It includes the head stand, tail stand, and overhead beams or sidebars.

- Filter Plates: These are the heart of the machine. A series of plates are lined up to form a "filter pack," creating hollow chambers between them where the slurry is pumped.

- Filter Cloths: A cloth is draped over each filter plate. This is the filter medium that allows the liquid to pass through but captures the solid particles. The weave and material of the cloth are critical to performance.

- Closing System: A hydraulic ram presses the filter pack together with tremendous force, sealing the chambers to withstand the high pressures of the filtration process.

The Filtration Cycle Step-by-Step

The operation follows a distinct, repeatable cycle.

- Closing the Press: The hydraulic system activates, pushing the plates tightly together to create a leak-proof seal.

- Filling the Chambers: A pump begins to feed the slurry into the press, filling all the empty chambers between the filter plates.

- Building Pressure (Filtration): As the pump continues to run, pressure inside the chambers builds. This pressure forces the liquid (now called filtrate) to pass through the filter cloth and exit via ports in the plates.

- Cake Formation: The solids are left behind, gradually building up on the filter cloths. This accumulation of solids is known as the filter cake. The filtration cycle continues until the chambers are packed full of dewatered cake.

- Opening and Discharge: The hydraulic system retracts, and the plates are separated one by one. The solid, dewatered filter cakes fall from between the plates into a hopper or conveyor below for disposal or further processing.

Key Types of Filter Presses

While the principle is the same, a crucial design difference separates filter presses into two main categories, each suited for different goals.

Chamber Filter Press

This is the standard and most common type of press. The internal volume of the chambers is fixed. It is a reliable and cost-effective workhorse for a wide range of dewatering applications.

Membrane Filter Press

Membrane filter presses have plates with a flexible, inflatable surface (the membrane). After the initial filtration cycle, water or compressed air is pumped behind the membrane, inflating it.

This action squeezes the filter cake, physically pressing out even more liquid. This extra step results in a significantly drier cake and a shorter overall cycle time.

Understanding the Trade-offs and Considerations

No technology is perfect for every situation. Understanding the advantages and limitations of a filter press is key to making an informed decision.

The Primary Advantages

Filter presses are widely used because they are highly effective. Their main benefits include high solids capture rates, the ability to produce an exceptionally dry filter cake, and a very clear filtrate. They are also mechanically simple and robust, leading to high reliability.

The Inherent Limitations

The most significant limitation is that it is a batch process, not a continuous one. The cycle must be stopped to discharge the cake, which can create bottlenecks in continuous production lines. The process can also be labor-intensive unless automated with features like automatic plate shifters and cloth washers.

Factors that Influence Performance

The success of a filter press operation depends heavily on the characteristics of the slurry being processed. Factors like particle size, solids concentration, and the use of chemical pre-treatment (flocculants) can dramatically impact filtration speed and final cake dryness.

Is a Filter Press Right for Your Application?

Choosing the right dewatering technology requires matching the equipment's capabilities to your specific operational goals.

- If your primary focus is achieving the highest possible cake dryness and maximizing liquid recovery: A membrane filter press is almost always the superior choice due to its cake-squeezing capability.

- If your primary focus is a robust, reliable, and lower-cost solution for general dewatering: A standard chamber filter press provides excellent performance for a wide array of applications.

- If your primary focus is a fully continuous and unattended operation: You should explore alternative technologies like a belt press or centrifuge, as the inherent batch nature of a filter press may not suit your workflow.

Ultimately, the filter press is a powerful and proven tool for achieving a high degree of solid-liquid separation.

Summary Table:

| Feature | Chamber Filter Press | Membrane Filter Press |

|---|---|---|

| Primary Use | General dewatering, cost-effective solution | Maximum cake dryness, high efficiency |

| Key Mechanism | Fixed chamber volume | Inflatable membrane for extra cake squeezing |

| Best For | Reliable, robust performance | Higher dryness and shorter cycle times |

| Cycle Type | Batch process | Batch process with enhanced dewatering |

Ready to optimize your solid-liquid separation process? KINTEK specializes in high-performance lab equipment and consumables, including filter presses tailored for your industry. Whether you need a reliable chamber press for general dewatering or a high-efficiency membrane press for maximum dryness, our solutions deliver clear filtrate and dry cake results. Contact us today to discuss your specific application and discover how KINTEK can enhance your laboratory's efficiency and reliability!

Visual Guide

Related Products

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What products are surface hardening? A Guide to Processes, Agents, and Applications

- How many types of annealing process are there? A Guide to the 3 Fundamental Categories

- Why Use a Water Bath Shaker in Anaerobic Digestion? Optimize Graphene Oxide & Iron Interaction

- What is the minimum temperature for sintering? It Depends on Your Material's Melting Point

- What is the difference between hardening and tempering? Achieve the Perfect Balance of Strength and Toughness

- Why is high-temperature regeneration in a laboratory furnace required for Na-Ce-SBA-15 catalysts? Learn More.

- What is the process of thin film in semiconductor? Build the Layers of Modern Electronics