The specialized furnace used for firing pottery is called a kiln. This is a thermally insulated chamber where raw, shaped clay is subjected to controlled high temperatures, chemically and physically transforming it from a fragile object into a hard, durable ceramic piece. The kiln is not merely an oven; it is a fundamental tool that defines the final character, color, and strength of the pottery.

While "kiln" is the correct term, the crucial understanding is that the type of kiln you use—primarily electric, gas, or wood—is one of the most significant artistic choices a potter makes, fundamentally dictating the final appearance of their work.

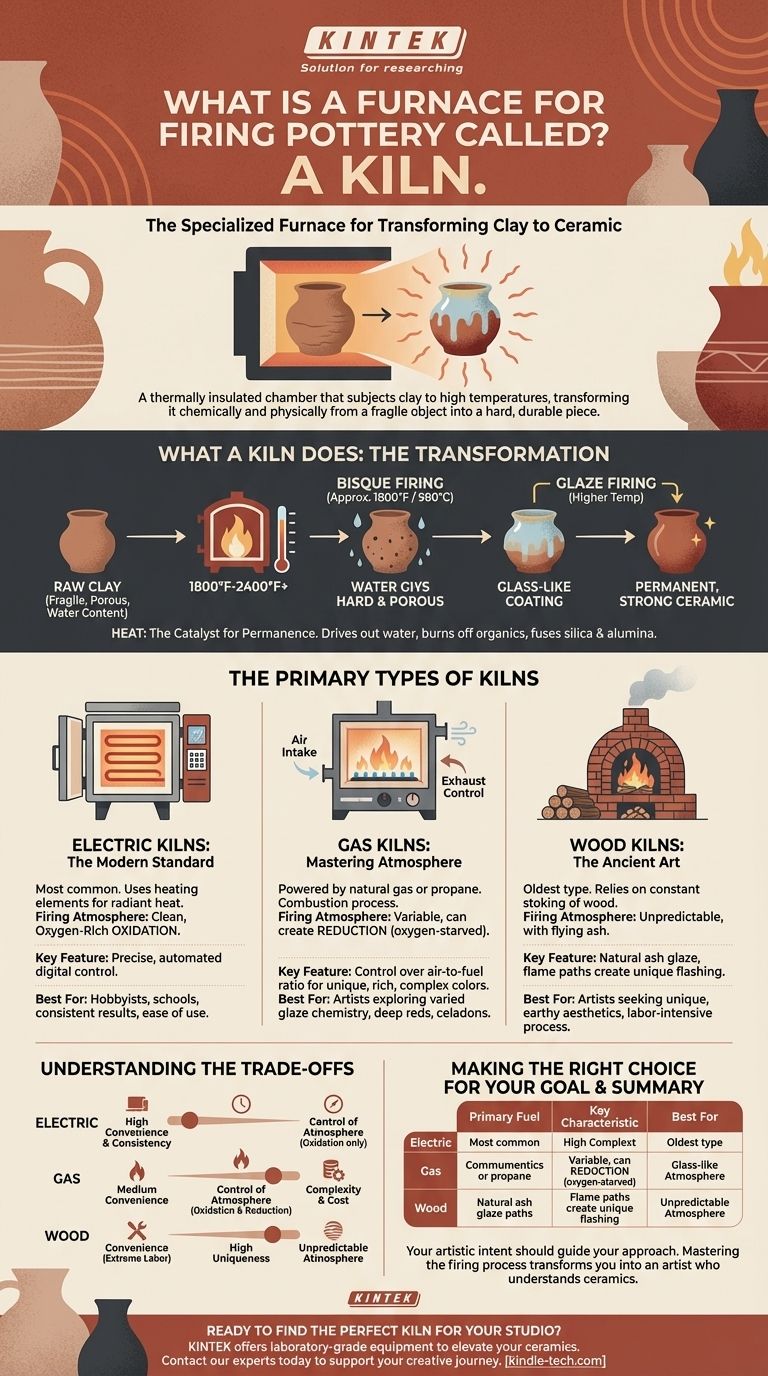

What a Kiln Does: The Transformation from Clay to Ceramic

A kiln’s purpose is to manage a controlled journey of heating and cooling. This process removes all water, fuses the clay particles together, and, in a second firing, melts glaze into a glass-like coating.

The Role of High Temperature

Heat is the catalyst for permanence. As the temperature rises inside a kiln, it drives out water molecules, burns off organic matter, and causes the silica and alumina particles in the clay to vitrify, or fuse together, creating a new, stone-like material.

The Two Critical Firing Stages

Most pottery is fired twice. The first firing, called a bisque firing, is done at a lower temperature (around 1800°F or 980°C) to make the clay pot hard and porous, ready for glazing. The second, a glaze firing, is done at a higher temperature to melt the applied glaze and fully mature the clay body.

The Primary Types of Kilns

The method used to generate heat is the primary distinction between kilns. Each type creates a different internal environment, or "atmosphere," which dramatically impacts the final result.

Electric Kilns: The Modern Standard

Electric kilns are the most common type found in schools, hobbyist studios, and small production potteries. They use heating elements—coils of high-resistance wire—to generate radiant heat.

They are prized for their ease of use, with digital controllers that allow for precise, automated firing schedules. They fire in a clean, oxygen-rich atmosphere known as oxidation.

Gas Kilns: Mastering Atmosphere

Gas kilns, powered by natural gas or propane, burn fuel to generate heat. This combustion process gives the potter a powerful variable to control: the air-to-fuel ratio.

By limiting the oxygen available, a potter can create a reduction atmosphere. This oxygen-starved environment forces glaze chemicals to seek oxygen from the clay body itself, producing dramatically different—and often richer and more complex—colors than an electric kiln can achieve.

Wood Kilns: The Ancient Art

Wood-fired kilns are the oldest type, relying on the constant stoking of wood to build temperature. This method is the most labor-intensive and least predictable, but it can yield results that are impossible to replicate in any other way.

Flying ash melts onto the pots to create a natural glaze, and the path of the flame creates unique flashing and color variations. Firing a wood kiln is often a communal event that can last for days.

Understanding the Trade-offs

Choosing a kiln type involves balancing convenience, cost, and desired aesthetic. There is no single "best" option; there is only the best option for a specific goal.

Electric: Convenience vs. Atmospheric Limitations

Electric kilns offer unmatched consistency and safety. However, their exclusively oxidative atmosphere means that the vibrant and often unpredictable effects of reduction glazes are generally not achievable without special measures.

Gas: Control vs. Complexity

Gas kilns provide the ultimate control over atmosphere, unlocking a vast palette of glaze possibilities. This control comes at the cost of increased complexity, higher initial investment, and significant ventilation and safety requirements.

Wood: Uniqueness vs. Extreme Labor

Wood firing offers the chance to create truly one-of-a-kind pieces marked by the process itself. This unique beauty is earned through immense physical labor, a deep understanding of thermodynamics, and a willingness to embrace unpredictable results.

Making the Right Choice for Your Goal

Your artistic intent should guide your approach to firing. Understanding what each kiln type offers is the key to matching the process to your desired outcome.

- If your primary focus is consistent results and ease of use: An electric kiln is your best starting point for learning the fundamentals and achieving reliable outcomes.

- If your primary focus is exploring rich, varied glaze chemistry: A gas kiln provides the atmospheric control necessary to produce the deep reds, celadons, and other effects associated with reduction firing.

- If your primary focus is on the artistic process and unique, earthy aesthetics: A wood kiln offers an unparalleled, though demanding, experience where the firing itself becomes part of the art.

Mastering the firing process transforms you from someone who makes pots into an artist who understands ceramics.

Summary Table:

| Kiln Type | Primary Fuel | Key Characteristic | Best For |

|---|---|---|---|

| Electric | Electricity | Clean, oxidation atmosphere; precise digital control | Hobbyists, schools, consistent results |

| Gas | Natural Gas / Propane | Reductive atmosphere; rich, complex glaze colors | Artists exploring varied glaze chemistry |

| Wood | Wood | Unique, unpredictable ash-glaze effects; labor-intensive process | Artists seeking unique, earthy aesthetics and process-driven art |

Ready to find the perfect kiln for your studio?

Whether you're a hobbyist seeking the consistency of an electric kiln or a professional artist exploring the rich glaze effects of a gas kiln, KINTEK has the laboratory-grade equipment you need to elevate your ceramics. Our expertise ensures you get the right tool for your artistic vision.

Contact our experts today to discuss your needs and discover how KINTEK can support your creative journey!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker