A laboratory drying oven is a fundamental piece of equipment used to remove moisture from samples, sterilize labware, and cure or harden materials. It accomplishes this by creating a precisely controlled, high-temperature environment through the circulation of hot air.

At its core, a laboratory drying oven is a precision tool designed for thermal processing at atmospheric pressure. Its defining feature is the use of forced air convection to ensure a stable and uniform temperature throughout its chamber for reliable, repeatable results.

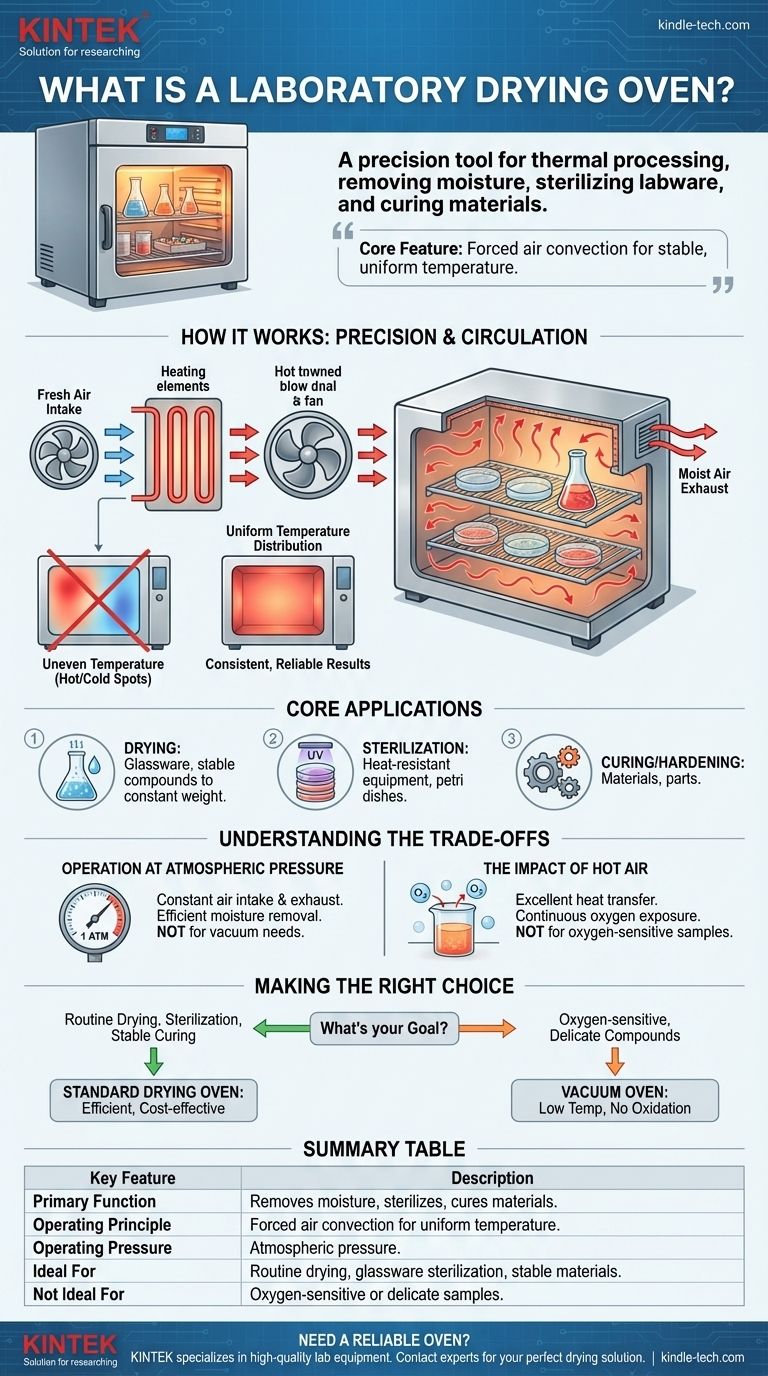

How a Drying Oven Achieves Precision

Understanding the mechanism of a drying oven reveals why it is a staple in scientific, clinical, and industrial settings. Its operation is based on a simple yet highly effective principle.

The Principle of Air Circulation

A drying oven works by drawing in fresh ambient air and passing it over electric heating elements. A fan then dissipates this hot air throughout the insulated chamber, ensuring it reaches every surface.

As the hot air circulates and absorbs moisture from the samples or equipment inside, the now-moist air is vented out, allowing the cycle to continue with fresh, dry air.

Uniform Temperature Distribution

The primary goal of this constant air circulation is to achieve a uniform temperature. This process eliminates potential hot or cold spots within the chamber, which is critical for ensuring that an entire sample is dried or sterilized evenly.

This consistency is essential for scientific validity, whether you are drying a chemical sample to a constant weight or sterilizing a batch of glass petri dishes.

Core Laboratory Applications

The functions of a drying oven are straightforward but vital for daily lab operations.

Common tasks include heating materials to a specific temperature, thoroughly drying glassware to prevent contamination, hardening parts or samples through curing, and sterilizing heat-resistant equipment.

Understanding the Trade-offs

While incredibly versatile, the standard drying oven has specific characteristics that define its ideal use cases and its limitations. Its design is optimized for efficiency in a particular environment.

Operation at Atmospheric Pressure

A key feature is that these ovens operate at normal atmospheric pressure. The constant intake and exhaust of air is fundamental to their design for removing moisture.

This distinguishes them from vacuum ovens, which are required for drying delicate samples that could be damaged by high temperatures or oxidation.

The Impact of Hot Air

The use of circulating hot air is excellent for heat transfer but means that samples are constantly exposed to oxygen.

For most routine applications like drying glassware or stable compounds, this is not an issue. However, for materials that can easily oxidize or degrade in the presence of air, this type of oven would be unsuitable.

Making the Right Choice for Your Goal

Selecting the correct heating equipment depends entirely on the material you are working with and your desired outcome.

- If your primary focus is routine drying and sterilization: A standard laboratory drying oven is the most efficient and cost-effective tool for items like glassware, metal instruments, and stable powders.

- If your primary focus is hardening or curing materials: The uniform heat distribution of a drying oven ensures consistent results across the entire sample, making it ideal for many industrial and research applications.

- If your primary focus is drying oxygen-sensitive or delicate compounds: You must consider an alternative like a vacuum oven, which removes the atmosphere to dry samples at lower temperatures without oxidation.

Ultimately, understanding the core mechanism of heated air circulation is the key to leveraging a drying oven safely and effectively for your specific task.

Summary Table:

| Key Feature | Description |

|---|---|

| Primary Function | Removes moisture, sterilizes labware, cures/hardens materials. |

| Operating Principle | Forced air convection for uniform temperature distribution. |

| Operating Pressure | Atmospheric pressure. |

| Ideal For | Routine drying, sterilization of glassware, curing stable materials. |

| Not Ideal For | Oxygen-sensitive or delicate samples (requires a vacuum oven). |

Need a Reliable Drying Oven for Your Lab?

A laboratory drying oven is a cornerstone of efficient lab operations, ensuring precise and uniform heating for critical tasks. KINTEK specializes in providing high-quality lab equipment and consumables tailored to your specific needs.

Whether you are drying samples to a constant weight, sterilizing glassware, or curing materials, the right oven is key to achieving consistent, repeatable results.

Let us help you enhance your lab's capabilities. Contact our experts today to find the perfect drying solution for your application!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

People Also Ask

- What are the types of oven used in laboratory? Choose the Right Heating Solution for Your Lab

- What is ashing in mineral analysis? Key Steps for Accurate Elemental Analysis

- What is the difference between a retort and a muffle furnace? Uncover the Truth About Indirect Heating

- What is the function of electric furnace in laboratory? Precision Heat for Material Transformation

- What are the risks of using a muffle furnace? Mitigate Thermal, Material, and Operational Hazards

- What are the 4 types of heat treatment for steel? Master Annealing, Normalizing, Hardening & Tempering

- Which furnace is used for sintering? A Guide to Choosing the Right System for Your Application

- What key experimental conditions does a box resistance furnace provide for S30403? Master High-Temp Simulation