In most professional settings, a laboratory furnace is simply called a laboratory furnace. While this is the general term, more specific names like muffle furnace or tube furnace are used to describe its design and primary application. These devices are purpose-built for high-temperature thermal processing in a controlled laboratory environment.

The term "laboratory furnace" describes a category of high-temperature heating equipment. The specific name used often depends on the furnace's physical construction, which in turn dictates its ideal application, such as general-purpose heating or processing materials in a controlled atmosphere.

What Defines a Laboratory Furnace?

A laboratory furnace is fundamentally a thermally insulated chamber with a method for generating extreme heat, far beyond the capability of a standard oven. Its purpose is to induce physical or chemical changes in a material sample.

Core Function: High-Temperature Processing

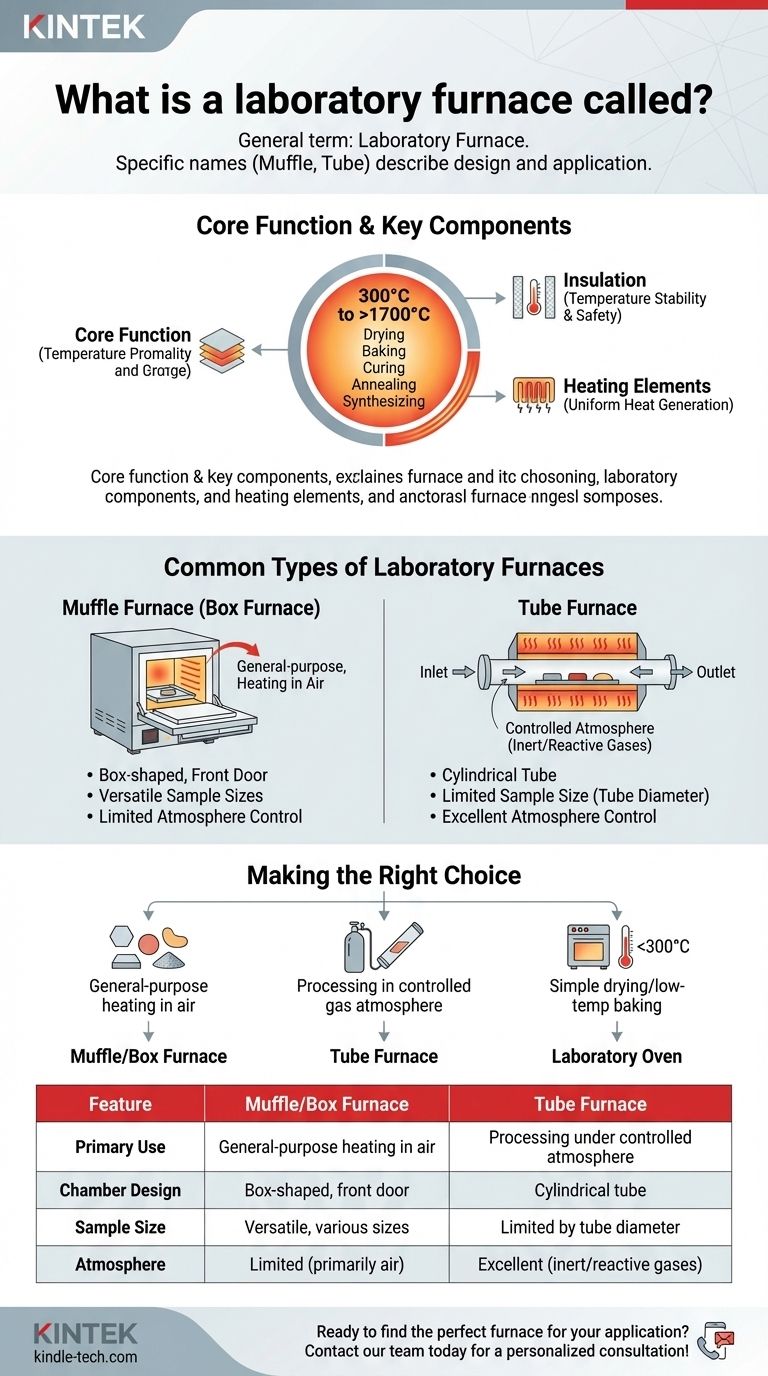

The primary role of a furnace is to heat materials to very high temperatures, typically ranging from 300°C to over 1700°C (572°F to 3092°F).

This enables critical processes like drying to remove all moisture, baking to heat a sample without dehumidification, or curing to harden a material. It's also used for annealing metals, synthesizing materials, and testing for heat resistance.

Key Components: Insulation and Heating Elements

A furnace consists of a central chamber surrounded by high-performance thermal insulation. This ensures temperature stability and operator safety.

Heat is generated by electric resistance heating elements. These are strategically placed to provide uniform heat throughout the chamber, ensuring the entire sample is processed evenly.

Common Types of Laboratory Furnaces

While they share a core function, the physical design of a furnace determines its best use. The two most common designs are the muffle (or box) furnace and the tube furnace.

The Muffle Furnace (Box Furnace)

This is the most common type of general-purpose laboratory furnace. It has a box-shaped chamber, accessed by a front-opening door.

Its name comes from the "muffle," an inner chamber that historically protected samples from the byproducts of fuel combustion. In modern electric furnaces, the term persists and refers to the separate heating chamber that ensures uniform heating.

The Tube Furnace

A tube furnace uses a cylindrical chamber, typically made of ceramic or quartz, that passes through the heating elements. Samples are placed inside this tube.

This design is specialized for processes requiring a controlled atmosphere. Gases (such as nitrogen or argon) can be flowed through the tube to prevent oxidation or to facilitate specific chemical reactions, a task that is difficult to achieve in a standard box furnace.

Understanding the Trade-offs

Choosing a furnace type involves balancing versatility, sample size, and atmospheric requirements. Each design has clear advantages and limitations.

Muffle Furnace: Versatility vs. Atmosphere Control

The strength of a muffle or box furnace is its versatility. Its large, accessible chamber can accommodate a wide variety of sample sizes and shapes, making it a workhorse for many labs.

Its primary limitation is atmosphere control. While samples are heated in air, creating a specific, non-air gas environment is not its primary design function and requires significant modification.

Tube Furnace: Atmosphere Control vs. Sample Size

The tube furnace excels at precise atmospheric control, which is essential for sensitive material synthesis, testing, and chemical reactions.

However, it is limited by the diameter of the tube. This restricts the size and shape of the samples that can be processed, making it a specialized tool rather than a general-purpose one.

Making the Right Choice for Your Application

Your specific scientific goal dictates which type of heating equipment is most appropriate.

- If your primary focus is general-purpose heating of various samples in air: A muffle furnace (or box furnace) is the standard, versatile choice for its large capacity and ease of use.

- If your primary focus is material processing in a controlled gas atmosphere: A tube furnace is specifically designed for flowing inert or reactive gases over a sample during heating.

- If your primary focus is simple drying or low-temperature baking (below 300°C): A laboratory oven, which offers less heat but finer low-temperature control, is often the more suitable and cost-effective instrument.

Understanding the distinction between furnace types ensures you select the precise tool to achieve your specific scientific goal.

Summary Table:

| Feature | Muffle/Box Furnace | Tube Furnace |

|---|---|---|

| Primary Use | General-purpose heating in air | Processing under controlled atmosphere |

| Chamber Design | Box-shaped, front door | Cylindrical tube |

| Sample Size/Shape | Versatile, accommodates various sizes | Limited by tube diameter |

| Atmosphere Control | Limited (primarily air) | Excellent (inert/reactive gases) |

Ready to find the perfect furnace for your application?

KINTEK specializes in high-performance laboratory furnaces and consumables. Whether you need the versatile capacity of a muffle furnace or the precise atmosphere control of a tube furnace, our experts will help you select the ideal equipment to enhance your lab's efficiency and accuracy.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the advantages of a muffle furnace? Achieve Purity and Precision in High-Temp Processing

- What is the mechanism of a muffle furnace? Master Precise, Contaminant-Free Heating

- Which furnace is used for sintering? A Guide to Choosing the Right System for Your Application

- How is a high-temperature box furnace used for 500-hour oxidation testing? Simulate Real-World Superalloy Performance

- Why must titanium plates be processed in a calcination furnace? Unlock Anatase Phase and Purity

- Why is a laboratory drying oven essential for biomass liquefaction? Ensure Accurate Conversion Rate Calculations

- What is the oven in a biology laboratory? Essential for Sterilization and Sample Drying

- How does the liquid environment in a molten salt furnace control carbon pore size? Master Precision Carbonization