While several low-temperature brazing alloys exist, the concept of using pressure to join materials at lower temperatures points to a different and more fundamental category of processes known as solid-state joining. These methods, including sintering, do not rely on melting a filler metal like traditional brazing. Instead, they use pressure and heat well below the materials' melting points to create a powerful atomic bond.

The search for a "low-temperature brazing" method often leads to a more fundamental solution: solid-state joining processes. These techniques avoid melting altogether, using pressure and controlled heat to bond materials, which prevents the thermal damage and distortion associated with traditional high-heat methods.

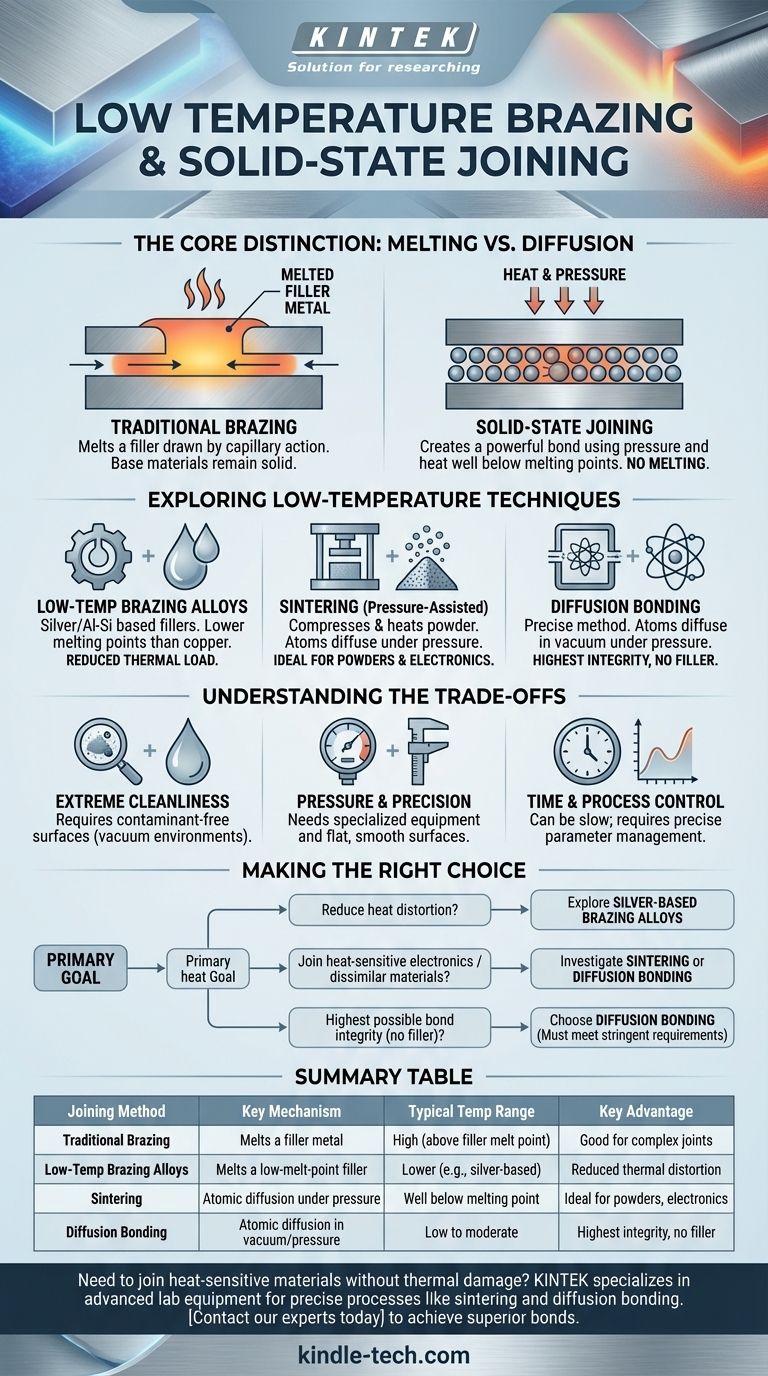

Brazing vs. Solid-State Joining: A Core Distinction

To find the right solution, we must first clarify the difference between these two joining philosophies. They achieve a similar outcome through entirely different physical mechanisms.

How Traditional Brazing Works

Brazing is a process that joins materials by melting a filler metal, which is drawn into the joint by capillary action. The key is that the filler metal has a lower melting point than the base materials being joined. The base materials themselves never melt.

The Principle of Solid-State Joining

Solid-state processes create a bond without melting any material. Instead, they use a combination of heat and pressure to force the atoms of the two surfaces into such close contact that they form a continuous, metallic bond.

Sintering is a prime example of this. When powdered materials are compressed and heated, the applied pressure allows the atoms at the particle surfaces to diffuse and bond at temperatures far below their melting point.

Exploring Low-Temperature Joining Techniques

The underlying goal—joining materials without high heat—can be achieved through several advanced methods.

Low-Temperature Brazing Alloys

It is important to note that lower-temperature forms of traditional brazing do exist. Alloys based on silver or aluminum-silicon, for example, have significantly lower melting points than conventional copper-based fillers, reducing the thermal load on the base parts.

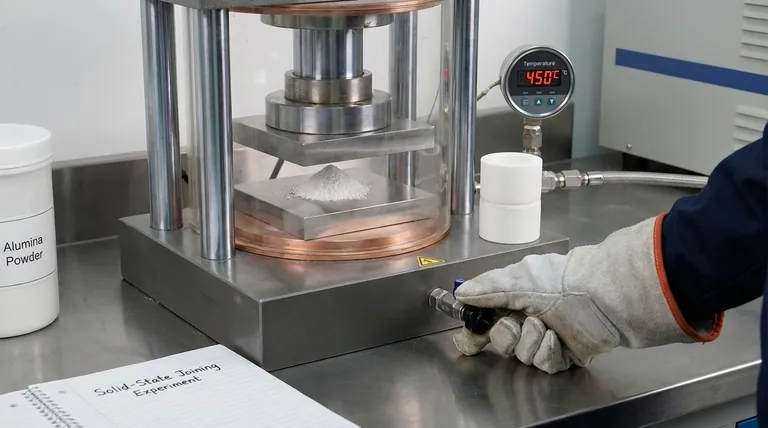

Sintering (Pressure-Assisted Bonding)

As mentioned in the reference, applying significant pressure is the key to low-temperature sintering. This technique is most common in powder metallurgy for creating solid parts from metal powders, but the principle is also used for bonding electronic components with nano-particle pastes.

Diffusion Bonding

Diffusion bonding is arguably the most precise solid-state joining method. Two parts with extremely flat and clean surfaces are held together under pressure in a vacuum or inert atmosphere. Over time, atoms diffuse across the boundary, effectively eliminating the original interface and creating a single, solid piece.

Understanding the Trade-offs

While solid-state processes solve the problem of heat, they introduce their own set of demanding requirements. Choosing the right method depends on understanding these challenges.

The Need for Extreme Cleanliness

Solid-state bonding relies on direct atom-to-atom contact. Any surface contaminants, such as oxides or oils, will act as a barrier and prevent a bond from forming. This often requires processing in a vacuum or highly controlled environments.

The Requirement for Pressure and Precision

These methods are not as forgiving as brazing. They require specialized equipment like hydraulic presses or vacuum furnaces to apply uniform pressure. Furthermore, the mating surfaces of the parts must be exceptionally flat and smooth to ensure intimate contact across the entire joint.

Time and Process Control

Diffusion bonding can be a slow process, sometimes taking several hours to complete. Sintering and other solid-state methods require extremely precise control over temperature, time, and pressure to achieve the desired material properties.

Making the Right Choice for Your Goal

Selecting the correct process requires aligning the technique with your primary objective.

- If your primary focus is reducing heat distortion in a structural joint: Explore lower-temperature silver-based brazing alloys as a practical and accessible first step.

- If your primary focus is joining heat-sensitive electronics or dissimilar materials: Investigate solid-state processes like pressure-assisted sintering (with conductive pastes) or diffusion bonding.

- If your primary focus is achieving the highest possible bond integrity with no filler material: Diffusion bonding is the definitive choice, provided you can meet its stringent surface preparation and equipment requirements.

By understanding the distinction between melting a filler and promoting atomic diffusion, you can select the precise joining method that protects your components and achieves a superior bond.

Summary Table:

| Joining Method | Key Mechanism | Typical Temperature Range | Key Advantage |

|---|---|---|---|

| Traditional Brazing | Melts a filler metal | High (above filler melt point) | Good for complex joints |

| Low-Temp Brazing Alloys | Melts a low-melt-point filler | Lower (e.g., silver-based) | Reduced thermal distortion |

| Sintering | Atomic diffusion under pressure | Well below melting point | Ideal for powders, electronics |

| Diffusion Bonding | Atomic diffusion in vacuum/pressure | Low to moderate | Highest integrity, no filler |

Need to join heat-sensitive or dissimilar materials without thermal damage? KINTEK specializes in advanced lab equipment and consumables for precise thermal processes like sintering and diffusion bonding. Our expertise helps you achieve superior, reliable bonds for your most demanding applications. Contact our experts today to discuss your specific joining challenges and discover the ideal solution for your laboratory needs.

Visual Guide

Related Products

- Advanced Engineering Fine Ceramics Low Temperature Alumina Granulation Powder

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of using a solid precursor sublimation device? Enhance Nucleation in MW-SWP CVD Processes

- Why is the ball milling process utilized in the preparation of Al2O3-SiC pre-mixed powders? Boost Sintering Performance

- Which ceramic materials are most widely used? A Guide to Alumina, Zirconia, SiC, and Si3N4

- What is the purpose of processing dried Aluminum Nitride mixed powder with a 200-mesh standard sieving system?

- Why must YAG:Ce powder from aerosol pyrolysis undergo thermal annealing? Unlock Peak Phosphor Performance