Yes, under specific conditions, the inhalation of certain carbon nanotubes is toxic. The risk is not driven by the carbon itself, but by the physical shape and durability of the nanotubes. Long, straight, and rigid carbon nanotubes can behave like asbestos fibers in the lungs, triggering a persistent inflammatory response that can lead to serious diseases, including cancer.

The core issue with carbon nanotube (CNT) safety is a structural one. Toxicity is dictated not by chemical composition, but by physical dimension. When CNTs are long, thin, and durable, they can mimic asbestos, evading the body's natural defenses and initiating a cascade of inflammation that can lead to chronic lung disease.

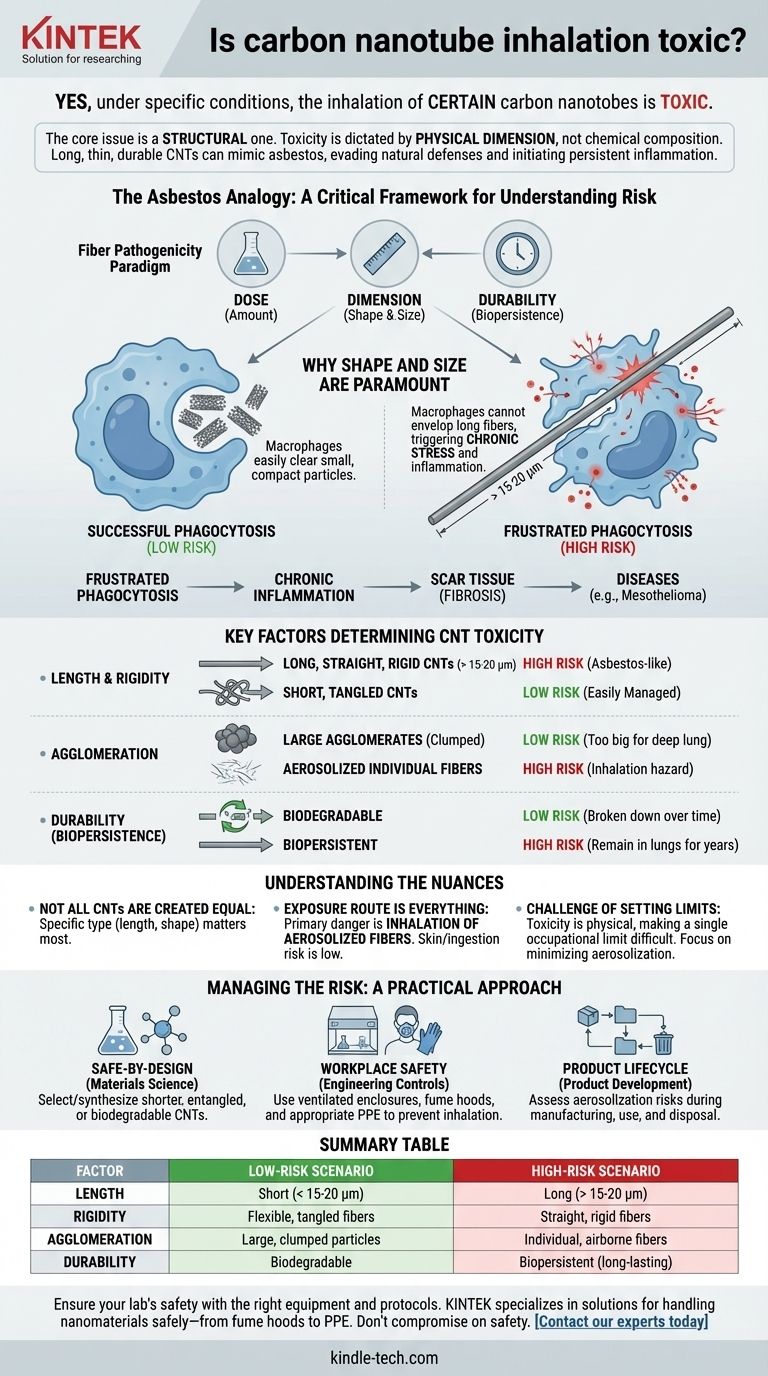

The Asbestos Analogy: A Critical Framework for Understanding Risk

To understand CNT toxicity, we must first understand why asbestos is dangerous. The scientific community uses a model called the fiber pathogenicity paradigm, which states that the toxicity of any inhaled fiber is determined by three key factors: Dose, Dimension, and Durability.

Why Shape and Size are Paramount

The most critical factor is dimension. The body's immune cells, called macrophages, are the lungs' cleanup crew. They effectively engulf and remove small, compact particles.

However, when faced with long, thin fibers (typically longer than 15-20 micrometers), macrophages cannot fully envelop them. This leads to a critical failure state.

The Mechanism: Frustrated Phagocytosis

This failure is known as frustrated phagocytosis. The macrophage attempts to engulf the long fiber but cannot, triggering a state of chronic stress.

In this stressed state, the cell releases a flood of inflammatory signals and destructive enzymes. This process, repeated endlessly as new cells try and fail to clear the indestructible fiber, creates a site of persistent, damaging inflammation.

From Inflammation to Disease

This chronic inflammation is the root cause of asbestos-related diseases. Over years, it leads to the formation of scar tissue (fibrosis), which impairs lung function.

Most critically, this inflammation in the lining of the lung (the pleura) is what can eventually lead to mesothelioma, the aggressive and signature cancer of asbestos exposure. Studies have shown that long, rigid CNTs can cause this same disease in animal models.

Key Factors Determining CNT Toxicity

The term "carbon nanotube" describes a vast family of materials. Their potential for harm varies dramatically based on their specific physical characteristics.

Length and Rigidity are the Primary Indicators

The danger is almost exclusively associated with long, straight, and rigid CNTs. These are the structures that cannot be cleared by macrophages and initiate frustrated phagocytosis.

Conversely, short CNTs, or those that are highly tangled and flexible, are more easily managed by immune cells and do not present the same asbestos-like risk.

The Role of Agglomeration

In many applications, CNTs are not present as individual, airborne fibers. They are often tightly clumped together in agglomerates.

These large clumps are generally too big to be inhaled deep into the lungs where the most severe damage occurs. The primary risk comes from processes that generate fine aerosols of individual, un-clumped CNT fibers, such as sonication or handling dry powders.

Durability and Biodegradation (Biopersistence)

The final factor is durability, or biopersistence. If a fiber can be broken down by the body over time, its potential for harm is significantly reduced.

Some research suggests that certain enzymes in the body can slowly degrade CNTs. However, this process is slow and not guaranteed, meaning many CNTs can be considered highly biopersistent, remaining in the lung tissue for years or even a lifetime.

Understanding the Nuances and Common Misconceptions

It is crucial to be precise when discussing this topic. A lack of nuance can lead to either unnecessary alarm or dangerous complacency.

Not All CNTs are Created Equal

Blanket statements about CNTs being "toxic" or "safe" are unhelpful. The specific type of CNT matters more than anything else. A material composed of short, tangled nanotubes poses a fundamentally different and lower risk than one containing long, needle-like nanotubes.

Exposure Route is Everything

The primary danger is the inhalation of aerosolized fibers. The risk of CNTs causing harm through skin contact or ingestion is considered to be exceptionally low in comparison. Workplace safety protocols must therefore focus on preventing airborne exposure.

The Challenge of Setting Exposure Limits

Because toxicity is tied to physical form rather than just chemical substance, establishing a single "safe" occupational exposure limit (like mg/m³) for all CNTs is incredibly difficult. The focus of industrial hygiene has shifted to minimizing any potential for aerosolization of high-risk CNT structures.

Managing the Risk: A Practical Approach

Understanding the mechanism of toxicity empowers us to manage the risk effectively. The goal is to prevent long, rigid, and durable fibers from reaching the deep lung.

- If your primary focus is materials science or engineering: Prioritize "safe-by-design" principles. When possible, select or synthesize CNTs that are shorter, more entangled, or have surfaces functionalized to encourage biodegradation.

- If your primary focus is workplace safety: Implement strict engineering controls. Handle CNTs, especially dry powders, in ventilated enclosures or fume hoods, and use appropriate personal protective equipment (PPE) to prevent inhalation.

- If your primary focus is product development: Assess the lifecycle of your product. Consider whether CNTs could become aerosolized during manufacturing, use, or disposal, and design processes to mitigate this risk.

By focusing on the physical properties that drive toxicity, we can harness the remarkable benefits of carbon nanotubes while implementing targeted and effective safety strategies.

Summary Table:

| Factor | Low-Risk Scenario | High-Risk Scenario |

|---|---|---|

| Length | Short (< 15-20 µm) | Long (> 15-20 µm) |

| Rigidity | Flexible, tangled fibers | Straight, rigid fibers |

| Agglomeration | Large, clumped particles | Individual, airborne fibers |

| Durability | Biodegradable | Biopersistent (long-lasting) |

Ensure your lab's safety with the right equipment and protocols.

Carbon nanotubes offer incredible potential, but managing inhalation risks is critical for protecting your team and research. At KINTEK, we specialize in providing the lab equipment and consumables you need to handle nanomaterials safely—from fume hoods and filtration systems to PPE and specialized containers.

Don't compromise on safety. Let us help you implement effective controls for handling CNTs and other advanced materials. Contact our experts today to discuss your laboratory's specific needs and how we can support your research with reliable, safety-focused solutions.

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Conductive Carbon Fiber Brush for Static Removal and Cleaning

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Automatic Laboratory Heat Press Machine

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- Is plastic pyrolysis harmful? The Hidden Dangers of Plastic Waste Conversion

- What are the products of sintering? Achieve Durable, Complex Parts from Powder

- What can XRF be used on? Analyze Solids, Liquids, Powders & More

- How does a constant temperature drying oven contribute to Bi2O3/GO thin films? Expert Curing for Superior Adhesion

- Why KBr is used in FTIR system? The Key to Accurate Mid-IR Spectral Analysis

- What are the applications of stainless steel? Unlock Its Versatility for Your Project

- What are the safety precautions for forging? A Complete Guide to Protecting Against Heat, Force, and Fumes

- What are the analytical used in laboratory? Choose the Right Tool for Your Lab's Needs