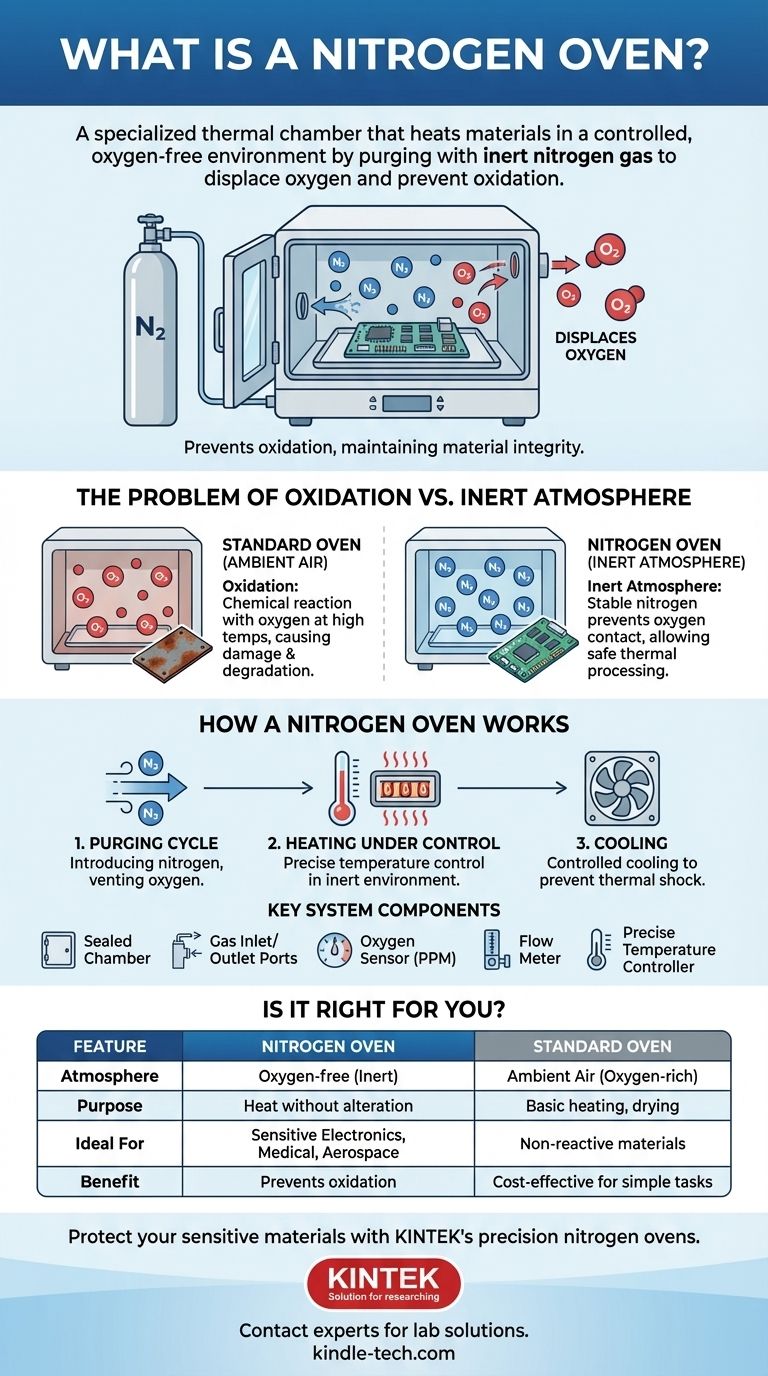

At its core, a nitrogen oven is a specialized thermal chamber that heats materials in a controlled, oxygen-free environment. Unlike a standard oven that uses ambient air, a nitrogen oven purges the chamber with inert nitrogen gas to displace oxygen. This process is critical for preventing oxidation, a chemical reaction that can damage or degrade sensitive components at high temperatures.

The fundamental purpose of a nitrogen oven is not just to heat something, but to heat it without altering its chemical properties. It achieves this by replacing the highly reactive oxygen in the air with non-reactive nitrogen, creating a protective atmosphere for the materials inside.

Why You Can't Just Use a Standard Oven

The critical difference between a nitrogen oven and a conventional oven comes down to the atmosphere inside the chamber. Understanding this distinction reveals why such specialized equipment is necessary for high-stakes applications.

The Problem of Oxidation

Oxidation is a chemical reaction that occurs when a substance is exposed to oxygen. A common example is iron rusting. At elevated temperatures, this process accelerates dramatically, causing discoloration, weakening, and changes in the electrical properties of many materials.

In a standard oven, heating a sensitive electronic component or a reactive chemical compound would expose it to a hot, oxygen-rich environment. This can lead to process failure, component damage, and unreliable end products.

How an Inert Atmosphere Solves the Problem

Nitrogen is an inert gas, meaning it is stable and does not readily react with other elements. By flooding the oven chamber with nitrogen, the oxygen is physically pushed out, or "purged."

This creates an inert atmosphere—a protective blanket that prevents oxygen from coming into contact with the materials being heated. The components can then undergo the necessary thermal processing, such as curing or soldering, without the destructive effects of oxidation.

How a Nitrogen Oven Works

While the concept is straightforward, the execution requires specific engineering to maintain a precisely controlled environment. The process is a clear sequence of purging, heating, and cooling under controlled conditions.

The Principle of Purging

The core function begins by introducing a continuous, low-pressure flow of nitrogen gas into the sealed chamber. An outlet port allows the displaced air (containing oxygen and moisture) to vent out of the chamber. This purging cycle continues until the oxygen concentration drops to a predefined, extremely low level, often measured in parts per million (PPM).

Key System Components

A nitrogen oven is more than just a heated box with a gas line. Key components include:

- A fully sealed chamber to prevent outside air from leaking in.

- Gas inlet and outlet ports for controlling the nitrogen flow.

- An oxygen sensor (or analyzer) to monitor the internal atmosphere and ensure oxygen levels are acceptably low.

- A flow meter to regulate the volume of nitrogen being consumed.

- A precise temperature controller, just like a high-quality laboratory oven.

Understanding the Trade-offs

While essential for specific tasks, nitrogen ovens introduce complexities and costs that make them unsuitable for processes where oxidation is not a concern.

Increased Cost and Complexity

Nitrogen ovens are more expensive than their conventional counterparts due to the added components like seals, sensors, and gas delivery systems. The engineering required to maintain a truly inert atmosphere adds to the initial capital investment.

Ongoing Operational Costs

The primary operational cost is the continuous consumption of nitrogen gas. For large-scale or continuous operations, this requires a significant and reliable supply of nitrogen, either from high-pressure cylinders or a dedicated nitrogen generator.

Safety and Facility Requirements

Nitrogen itself is not toxic, but it displaces oxygen. A large leak in an improperly ventilated area could create an asphyxiation hazard. Proper installation, ventilation, and safety monitoring are therefore essential.

Is a Nitrogen Oven Right for Your Process?

Choosing the right thermal equipment depends entirely on the sensitivity of the material you are processing. The decision comes down to whether the cost of preventing oxidation is justified by the need for material integrity and process yield.

- If your primary focus is electronics manufacturing: A nitrogen oven is critical for high-quality solder reflow and curing sensitive adhesives, preventing weak joints and component failure.

- If your primary focus is medical device or aerospace applications: An inert atmosphere is often mandatory to ensure materials retain their specified structural and chemical properties after heat treatment.

- If your primary focus is simply drying or baking non-reactive materials: A standard industrial or laboratory oven is the more practical and cost-effective solution.

Ultimately, a nitrogen oven is an essential tool for any thermal process where the presence of oxygen is a liability.

Summary Table:

| Feature | Nitrogen Oven | Standard Oven |

|---|---|---|

| Internal Atmosphere | Oxygen-free (inert nitrogen) | Ambient air (oxygen-rich) |

| Primary Purpose | Heating without chemical alteration | Basic heating, drying, baking |

| Ideal For | Sensitive electronics, reactive materials | Non-reactive, robust materials |

| Key Benefit | Prevents oxidation, discoloration, and property changes | Cost-effective for simple processes |

Protect your sensitive materials from oxidation with KINTEK's precision nitrogen ovens.

Does your thermal process involve soldering electronics, curing adhesives, or heat-treating components that cannot tolerate oxygen? Our nitrogen ovens are engineered to provide a reliable, controlled inert atmosphere, ensuring your materials retain their integrity and performance.

KINTEK specializes in high-quality lab equipment, including nitrogen ovens designed for the exacting needs of laboratories and manufacturing facilities. Let us help you achieve superior process yields and product reliability.

Contact our experts today to discuss your application and find the perfect nitrogen oven solution for your lab.

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

People Also Ask

- Why is a laboratory-grade forced air drying oven required for alloy chip moisture analysis? Ensure Data Precision

- What is the function of a laboratory drying oven in Zr2.5Nb alloy pretreatment? Ensure Precise Corrosion Test Results

- What is the function of a laboratory oven in W18Cr4V steel sample preparation? Expert Microstructural Drying Guide

- What is the role of a laboratory drying oven in catalyst treatment? Ensure Structural Integrity & High Performance

- What is the primary purpose of using an electric drying oven for dense refractory bricks? Optimize Raw Material Prep