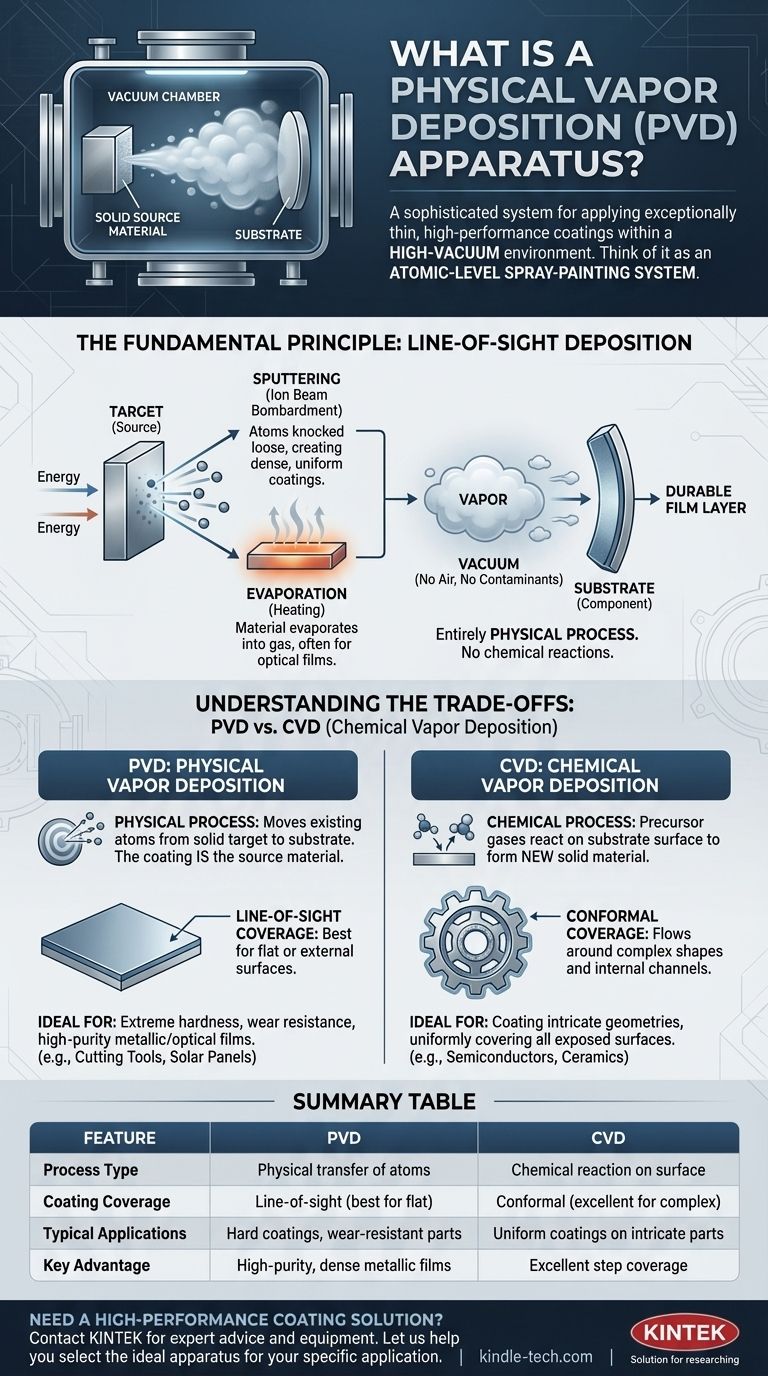

At its core, a Physical Vapor Deposition (PVD) apparatus is a sophisticated system designed to apply exceptionally thin, high-performance coatings onto a surface. It operates within a vacuum by physically transforming a solid source material into a vapor, which then travels and condenses onto a target object, known as the substrate, to form a durable film. This process is entirely physical, involving no chemical reactions to form the coating.

A PVD apparatus is best understood not as a single machine, but as a controlled environment for a physical transfer process. Think of it as an atomic-level spray-painting system, where individual atoms are dislodged from a source and precisely deposited onto a component inside a high-vacuum chamber.

The Fundamental Principle: Line-of-Sight Deposition

The entire PVD process hinges on the physical movement of material in a straight line from its source to the substrate it will coat.

From Source to Substrate

A PVD system bombards a solid block of coating material, called the target, with energy. This energy physically knocks atoms or molecules loose from the target, turning them into a vapor. This vapor then travels through the vacuum and condenses on the cooler substrate, building the film layer by layer.

The Critical Role of the Vacuum

The process must occur in a high vacuum for two key reasons. First, it removes air and other particles that would otherwise contaminate the coating or react with the vapor. Second, it ensures the vaporized atoms can travel unimpeded from the target to the substrate.

Common PVD Methods

There are two primary methods driven by the type of energy source used:

- Sputtering: An ion beam (like a molecular sandblaster) bombards the target, physically knocking atoms off its surface. This method creates very dense, uniform coatings.

- Evaporation: The target material is heated until it evaporates into a gas (similar to boiling water). This vapor then condenses onto the substrate. This is often used for materials like optical films.

Understanding the Trade-offs: PVD vs. Chemical Vapor Deposition (CVD)

To truly understand what a PVD apparatus does, it is essential to contrast it with its chemical counterpart, Chemical Vapor Deposition (CVD). While their applications can overlap, their underlying mechanisms are fundamentally different.

The Core Distinction: Physical vs. Chemical

PVD is a physical process. It moves existing atoms from a solid target to the substrate. The coating material is the same as the source material.

CVD is a chemical process. It introduces precursor gases into a chamber, which then react on the substrate's surface to form a new, solid material. The coating is a product of this chemical reaction.

Coverage and Complexity

Because PVD is a "line-of-sight" process, it excels at coating flat or externally facing surfaces. It struggles to evenly coat complex geometries with deep recesses or internal channels.

CVD, which uses gases, can flow around and into complex shapes, providing a more uniform (conformal) coating on all exposed surfaces, even non-line-of-sight ones.

Material and Temperature Constraints

PVD is exceptionally good at depositing materials with very high melting points, as well as pure metals and alloys, without altering their composition.

CVD processes often require very high temperatures to initiate the chemical reaction, which can potentially damage the substrate. However, it is uniquely suited for creating materials that are difficult to produce in solid target form, like carbon nanotubes or certain ceramics.

Making the Right Choice for Your Application

Selecting the right deposition technology depends entirely on the desired outcome for the final component.

- If your primary focus is extreme hardness and wear resistance: PVD is the standard for applying hard, inert coatings to cutting tools, engine parts, and aerospace components.

- If your primary focus is coating complex internal surfaces: CVD is often the superior choice due to its ability to conformally coat intricate geometries with a uniform film.

- If your primary focus is a pure, dense metallic or optical film: PVD provides exceptional control for depositing materials like aluminum on solar panels or titanium nitride for durable finishes.

Understanding this fundamental difference between physical transfer and chemical reaction is the key to selecting the right tool for your engineering challenge.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical transfer of atoms | Chemical reaction on surface |

| Coating Coverage | Line-of-sight (best for flat/external surfaces) | Conformal (excellent for complex geometries) |

| Typical Applications | Hard coatings for tools, wear-resistant parts, optical films | Uniform coatings on intricate parts, semiconductors, ceramics |

| Key Advantage | High-purity, dense metallic films; lower temperatures | Excellent step coverage on non-line-of-sight surfaces |

Need a high-performance coating solution for your lab or production line? The right deposition technology is critical for achieving the desired hardness, purity, and coverage on your components. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice on PVD and other coating systems. Let our experts help you select the ideal apparatus for your specific application. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications