At its core, a tablet punch is a precision-engineered tool used in a tablet press machine to compress granulated powder into a solid tablet. Working in conjunction with a die, the punches are the components that directly shape the material, determine the final tablet's size and form, and imprint any necessary markings like logos or score lines.

While the tablet press provides the force, the tablet punch and die are the critical tools that actually form the tablet. Their design and quality directly dictate the final product's consistency, appearance, and the overall efficiency of your manufacturing line.

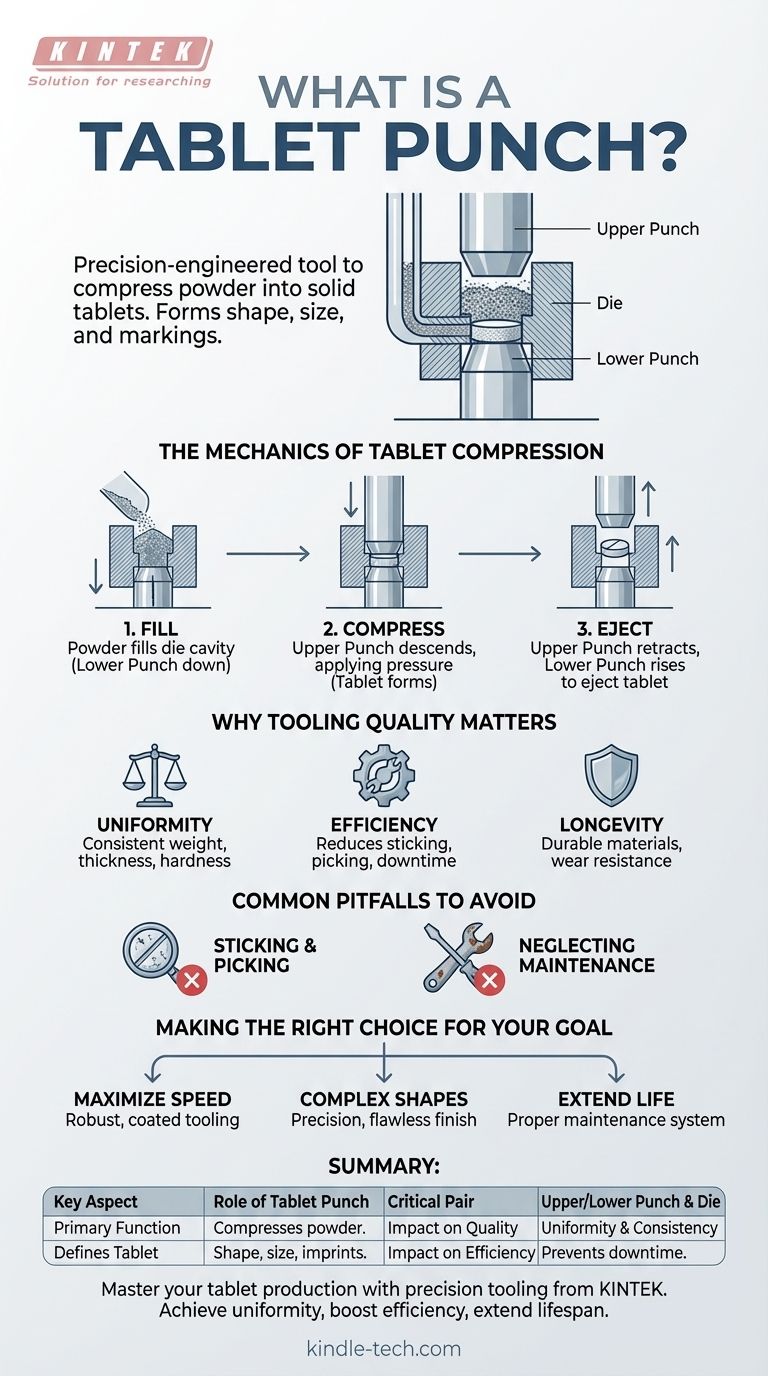

The Mechanics of Tablet Compression

To understand the punch, you must understand its role within the larger system. It is part of a matched set often referred to as "punch and die tooling" or "compression tools."

The Punch and Die: A Matched Pair

A tablet is not formed by a punch alone. The process requires an upper punch, a lower punch, and a die.

The die is a precision-machined cavity that dictates the tablet's diameter or perimeter. The powder formulation fills this cavity before compression.

The two punches move within the die to compress the powder.

The Role of the Upper and Lower Punch

The lower punch first descends in the die to create a cavity of a specific volume, which is then filled with the powder. It serves as the base of the mold.

The upper punch then descends into the die, applying the immense pressure required to compact the loose powder into a solid, bonded tablet.

After compression, the upper punch retracts, and the lower punch rises to eject the finished tablet from the die cavity.

Defining Every Aspect of the Tablet

The tooling set is responsible for all the physical characteristics of the final tablet.

The shape of the punch tips and the die cavity determines if the tablet is round, oval, or a custom shape. The engraving on the upper punch tip creates the logo, lettering, or score line. The volume of powder compressed determines the tablet's final weight and thickness.

Why Tooling Quality is Non-Negotiable

The performance of your entire tablet production line is directly tied to the quality of your punches and dies. Investing in superior quality tooling is not an expense; it's a requirement for efficient and reliable manufacturing.

Impact on Product Uniformity

High-quality, precisely manufactured tooling ensures that every tablet produced is consistent. This uniformity in weight, thickness, and hardness is essential for meeting regulatory standards and ensuring proper dosage.

Influence on Production Efficiency

Worn or poorly made punches can lead to a host of manufacturing problems, such as tablets sticking to the punch face. These issues cause machine stoppages, reduce output, and increase waste, directly impacting productivity.

Ensuring Tooling Longevity

Punches and dies are subjected to extreme pressures and abrasive materials. Superior tooling is made from hardened, high-grade steel with optional specialized coatings that resist wear, corrosion, and damage, extending their operational life and providing a better return on investment.

Common Pitfalls to Avoid

Even with the best equipment, improper handling or selection of tooling can lead to significant problems. Understanding these challenges is key to preventing them.

Mismatching Tooling to Formulation

Some powder formulations are abrasive, while others are corrosive or sticky. You must select a punch material and coating specifically suited to your product to prevent premature wear or compression issues.

Ignoring "Sticking" and "Picking"

Sticking is when the powder formulation adheres to the face of the punch, resulting in imperfect tablets. Picking occurs when small particles are lifted from the tablet's surface and become trapped in the details of the logo or lettering. Both are often symptoms of poor punch quality or an incompatible formulation.

Neglecting Proper Maintenance

Punches and dies are not disposable parts. They require a strict protocol for cleaning, polishing, and storage. Improper handling can cause nicks and scratches on the punch tips, which will transfer directly to every tablet produced.

Making the Right Choice for Your Goal

The optimal tooling depends entirely on your specific production objective.

- If your primary focus is maximizing production speed: Select robust tooling made from premium steel with coatings designed to reduce friction and withstand the high cyclical stress of a high-speed press.

- If your primary focus is producing tablets with complex shapes or detailed logos: Prioritize precision-engineered tooling with flawless punch tip finishes to prevent defects like picking and ensure crisp, clear imprints.

- If your primary focus is extending the life of your equipment: Invest in a comprehensive tooling maintenance system, including proper cleaning, polishing, and storage, to maximize the longevity of your punches and dies.

Ultimately, viewing your tablet punch not as a simple part but as a precision instrument is the first step toward mastering tablet manufacturing.

Summary Table:

| Key Aspect | Role of the Tablet Punch |

|---|---|

| Primary Function | Compresses powder into a solid tablet within a die. |

| Defines Tablet | Shape, size, thickness, and imprints (logos, scores). |

| Critical Pair | Works with an upper punch, lower punch, and die. |

| Impact on Quality | Directly influences tablet uniformity and consistency. |

| Impact on Efficiency | Quality tooling prevents sticking, picking, and downtime. |

Master your tablet production with precision tooling from KINTEK.

The right tablet punch and die set is not just a part—it's the heart of your manufacturing process, dictating product quality and line efficiency. KINTEK specializes in high-performance lab equipment and consumables, providing robust, precision-engineered tooling tailored to your formulation and production goals.

We help you:

- Achieve perfect tablet uniformity with tooling that ensures consistent weight, hardness, and appearance.

- Boost production efficiency by reducing defects like sticking and picking that cause costly downtime.

- Extend equipment lifespan with durable, coated punches designed to withstand abrasive or corrosive materials.

Ready to optimize your compression process? Contact our experts today to discuss your specific needs and discover how KINTEK's solutions can enhance your laboratory's productivity and output.

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are the advantages of a rotary tablet machine? Unlock High-Speed, Precise Tablet Production

- What is the function of rotary tablet press? High-Speed, High-Volume Tablet Production

- What is the process of making biomass pellets? A Step-by-Step Guide to Producing Clean Energy

- What are the different types of pelletizer machines? Choose the Right Machine for Your Scale

- What is the function of a tablet press? Transforming Powder into Precise, Uniform Tablets

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What type of die is used in pellet mills? Choose Between Flat Die and Ring Die for Your Production Scale

- What is the use of single punch tablet press? For Precise R&D and Small-Batch Tablet Production