The primary advantage of furnace brazing is its ability to produce exceptionally clean, strong, and dimensionally stable joints with high consistency, especially when manufacturing complex assemblies or large quantities of parts. By heating the entire component in a controlled atmosphere, it eliminates the localized thermal stress that causes distortion in other joining methods, while simultaneously allowing for multiple joints to be created in a single cycle.

Furnace brazing is not just another way to join metal; it is a precision manufacturing process. Its core advantage lies in using a uniformly heated, controlled environment to create superior, stress-free joints on an industrial scale, often combining the joining and heat-treating steps into one efficient operation.

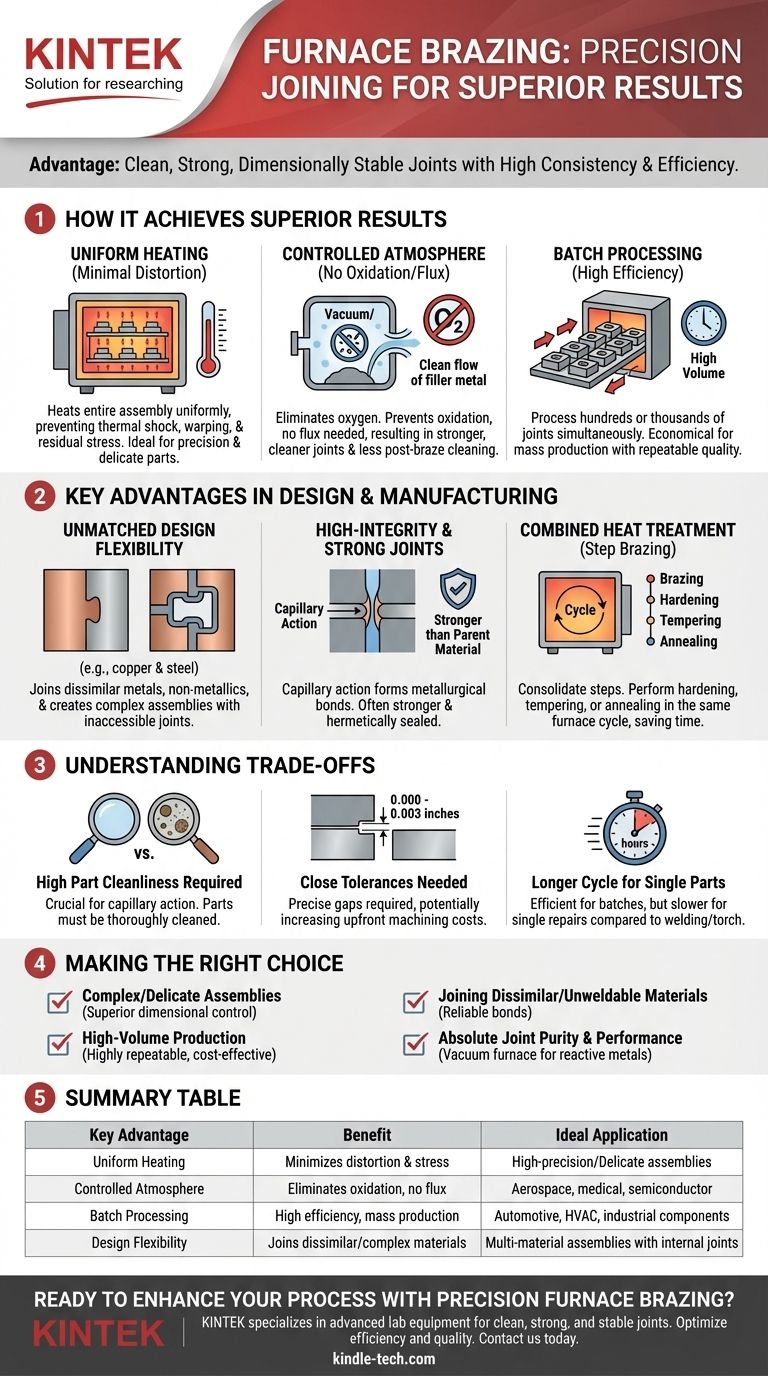

How Furnace Brazing Achieves Superior Results

To understand its advantages, you must first grasp the core principles that set furnace brazing apart from processes like welding or torch brazing.

Uniform Heating for Minimal Distortion

Furnace brazing heats the entire assembly uniformly within a controlled chamber. This slow, even heating and cooling cycle prevents the localized thermal shock and residual stress that cause parts to warp or distort—a common issue with welding.

This makes the process ideal for high-precision or delicate assemblies where maintaining tight tolerances is critical.

The Role of a Controlled Atmosphere

The process takes place in a furnace filled with a specific atmosphere, such as a vacuum or inert gases. This eliminates oxygen from the environment.

By preventing oxidation, the filler metal can flow cleanly into the joint without the need for corrosive chemical fluxes. This results in stronger, cleaner joints and eliminates the need for extensive post-braze cleaning, saving both time and cost.

Efficiency Through Batch Processing

Furnace brazing allows hundreds or even thousands of joints to be made simultaneously in a single batch. Whether it's one part with multiple joints or many individual parts, the entire furnace load is processed at once.

This batch capability makes it highly efficient and economical for mass production, delivering repeatable, high-quality results without requiring highly skilled operators for each joint.

Key Advantages in Design and Manufacturing

The principles of furnace brazing translate directly into tangible benefits for engineers and manufacturers.

Unmatched Design Flexibility

Furnace brazing liberates designers from the constraints of other methods. It excels at joining dissimilar metals (like copper to steel), thin materials to thick sections, and even non-metallic components like ceramics to metal.

Furthermore, it enables the creation of complex assemblies with internal or inaccessible joints that would be impossible to reach with a torch or welding gun.

High-Integrity and Strong Joints

The brazing process joins materials without melting them. It uses capillary action to draw a molten filler alloy into a narrow, precisely fitted gap between the base components.

This creates a metallurgical bond that is incredibly strong and hermetically sealed. In many cases, the resulting brazed joint is stronger than the parent materials themselves.

Combining Brazing with Heat Treatment

Because the process already involves a controlled heating and cooling cycle, it can be combined with other heat-treating processes.

For example, parts can be hardened, tempered, or annealed in the same furnace cycle as the brazing operation. This consolidation of steps, known as "step brazing," significantly reduces production time and handling costs.

Understanding the Trade-offs

No process is perfect. To use furnace brazing effectively, you must understand its limitations.

Requires High Part Cleanliness

The success of furnace brazing depends entirely on capillary action, which can be disrupted by contaminants like oils, grease, or oxides. Parts must be thoroughly cleaned before entering the furnace.

The Need for Close Tolerances

For capillary action to work effectively, the gap between the parts to be joined must be precise and consistent, typically ranging from 0.000 to 0.003 inches. Achieving these tolerances can increase upfront machining costs.

Longer Cycle Times for Single Parts

While highly efficient for batches, the heating and cooling cycle for a furnace can take several hours. For one-off repairs or prototypes, methods like welding or torch brazing are often faster.

Making the Right Choice for Your Goal

Use these guidelines to determine if furnace brazing is the right fit for your project.

- If your primary focus is complex or delicate assemblies: Furnace brazing offers superior dimensional control and the ability to join multiple inaccessible joints at once without distortion.

- If your primary focus is high-volume production: The process is highly repeatable and cost-effective, minimizing the need for skilled labor and post-braze cleaning.

- If your primary focus is joining dissimilar or unweldable materials: Furnace brazing provides a reliable method to create strong bonds between materials that cannot be joined by conventional fusion welding.

- If your primary focus is absolute joint purity and performance: Vacuum furnace brazing is the optimal choice, especially for reactive metals used in aerospace, medical, or semiconductor applications.

Ultimately, furnace brazing empowers engineers to create robust and intricate metal assemblies with a level of precision and efficiency that other methods cannot match.

Summary Table:

| Key Advantage | Benefit | Ideal Application |

|---|---|---|

| Uniform Heating | Minimizes distortion and residual stress | High-precision or delicate assemblies |

| Controlled Atmosphere | Eliminates oxidation, no flux required | Aerospace, medical, semiconductor parts |

| Batch Processing | High efficiency for mass production | Automotive, HVAC, and industrial components |

| Design Flexibility | Joins dissimilar metals and complex geometries | Multi-material assemblies with internal joints |

Ready to enhance your manufacturing process with precision furnace brazing?

At KINTEK, we specialize in providing advanced lab equipment and consumables that deliver the clean, strong, and dimensionally stable joints your projects demand. Whether you're working with complex assemblies, high-volume production, or joining dissimilar materials, our solutions ensure superior results with minimal distortion.

Contact us today to discuss how our furnace brazing expertise can optimize your laboratory's efficiency and output quality!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project