At its core, an electric arc furnace (EAF) is a high-powered system used to melt metals. While it is famously used for recycling steel scrap, its capabilities extend to a wide range of materials, including non-ferrous metals like aluminum, copper, lead, and zinc, along with their associated by-products such as dross.

The primary function of an electric arc furnace is to use the intense heat of an electrical arc—a plasma discharge between electrodes—to melt scrap metal and other charged materials. This makes it a cornerstone of modern metal recycling, particularly for steel production.

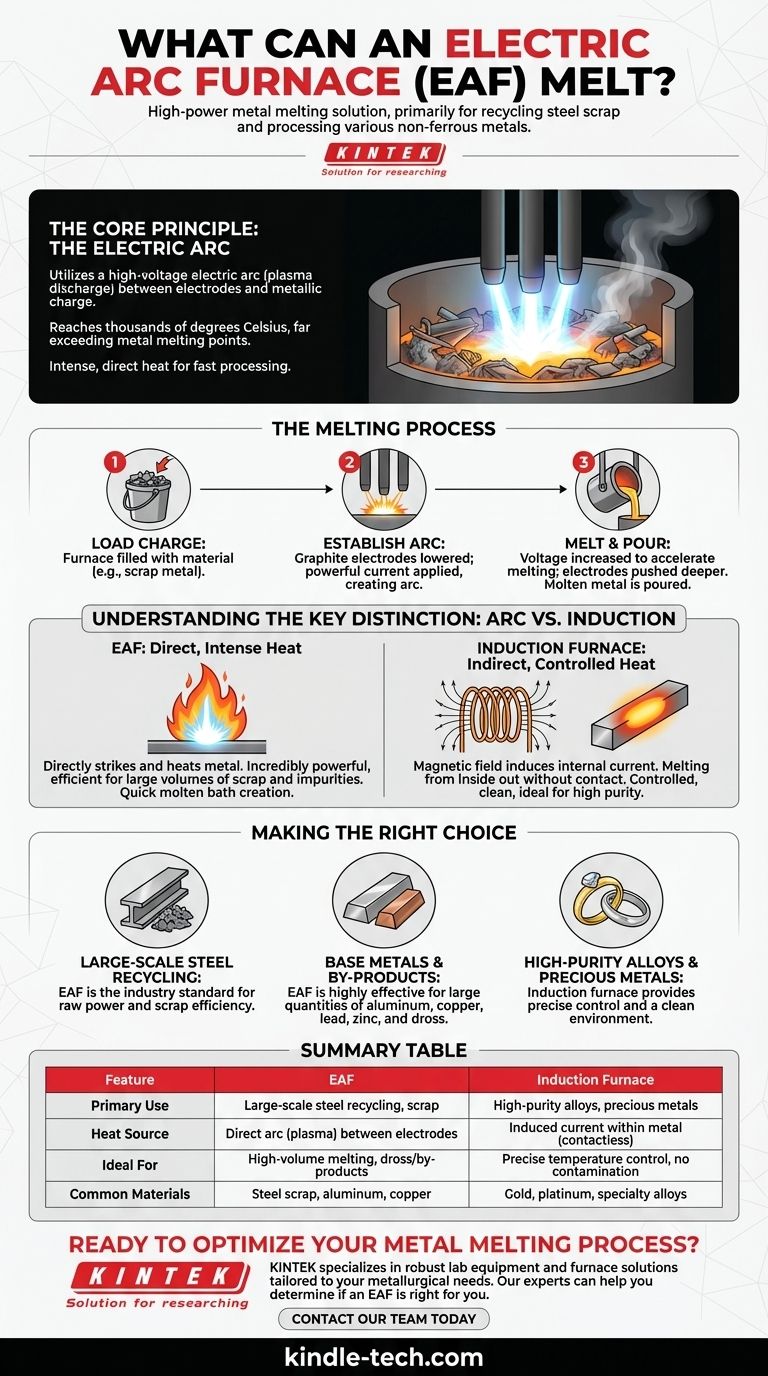

How an Electric Arc Furnace Works

To understand what an EAF can melt, it's essential to first understand its mechanism. Unlike other furnaces, its power comes from a direct and exceptionally hot energy source.

The Core Principle: The Electric Arc

The furnace's name describes its method precisely. It melts materials using a high-voltage electric arc that forms between massive carbon or graphite electrodes and the metallic charge inside the furnace.

This arc is a channel of plasma that can reach temperatures of thousands of degrees Celsius, far exceeding the melting point of most metals. This intense, direct heat transfer is what makes the EAF so effective and fast.

Key Components of the System

An EAF is constructed from several robust components designed to withstand extreme conditions.

The main body is a metal casing lined with refractory material that can tolerate the immense heat. A removable top allows for loading the charge, and a drain hole is used for pouring out the molten metal. The entire structure often sits on a cradle that can tilt to pour its contents.

The Melting Process

The process begins by loading the furnace with the material to be melted, typically scrap metal. The graphite electrodes are lowered into the furnace, and a powerful electric current is applied.

Once the arc is established and shielded by the electrodes, operators can increase the voltage to accelerate the melting process. Pushing the electrodes deeper into the charge (deep bathing) also enhances the speed and efficiency of the meltdown.

Understanding the Key Distinction: Arc vs. Induction

The EAF is not the only technology for melting metal. Its primary alternative is the induction furnace, and understanding the difference clarifies why an EAF is chosen for specific jobs.

EAF: Direct, Intense Heat

The electric arc directly strikes and heats the metal. This method is incredibly powerful and efficient for melting large volumes of material, especially scrap metal that may contain impurities. The sheer power of the arc can quickly create a molten bath from tons of solid steel.

Induction Furnace: Indirect, Controlled Heat

An induction furnace works differently. It uses a copper coil to generate a powerful magnetic field, which induces an electric current within the metal itself. This internal current generates heat, melting the metal from the inside out without any external contact or arc.

This process is generally more controlled, making it ideal for creating high-purity alloys or melting precious metals like gold and platinum where contamination must be avoided.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the material and the desired outcome.

- If your primary focus is large-scale steel recycling: The EAF is the undisputed industry standard due to its raw power and efficiency in handling scrap.

- If your primary focus is melting base metals like aluminum or copper: An EAF is highly effective, particularly for processing large quantities and managing by-products like dross.

- If your primary focus is creating high-purity alloys or melting precious metals: An induction furnace provides the precise temperature control and clean environment necessary for these sensitive applications.

Ultimately, the choice of furnace is dictated by the specific demands of the metallurgical task at hand.

Summary Table:

| Feature | Electric Arc Furnace (EAF) | Induction Furnace |

|---|---|---|

| Primary Use | Large-scale steel recycling, melting scrap metal | High-purity alloys, precious metals |

| Heat Source | Direct arc (plasma) between electrodes and charge | Induced current within the metal (contactless) |

| Ideal For | High-volume melting, processing dross and by-products | Precise temperature control, avoiding contamination |

| Common Materials | Steel scrap, aluminum, copper, lead, zinc | Gold, platinum, specialty alloys |

Ready to Optimize Your Metal Melting Process?

Whether you're involved in large-scale steel recycling or need to efficiently process non-ferrous metals, selecting the right equipment is critical to your success. At KINTEK, we specialize in providing robust and reliable lab equipment, including furnace solutions tailored to your specific metallurgical needs.

Our experts can help you determine if an electric arc furnace is the right choice for your application, ensuring you achieve maximum efficiency and productivity.

Contact our team today to discuss your project and discover how KINTEK can power your metal melting operations.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- How does a vacuum diffusion bonding furnace contribute to titanium laminates? Precision for Near-Alpha Alloys

- How can you determine when the temperature of a joint is hot enough to braze? Read the Flux for a Perfect Bond.

- Can hydrogen be produced from biomass? A Guide to Sustainable, Low-Carbon Hydrogen

- What function does a vacuum annealing furnace perform for tungsten-diamond coatings? Achieve Strong Metallurgical Bonds

- What is the temperature of the electric arc furnace? Key Insights for Efficient Steel Production

- What is high vacuum used for? Essential for Particle Beams and Advanced Lab Instruments

- How does a vertical cylindrical furnace facilitate the titanium electrolysis process? Precision Heat & Shielding

- What process conditions does vacuum heating equipment provide for organic electrolytes? Achieve Superior Infiltration