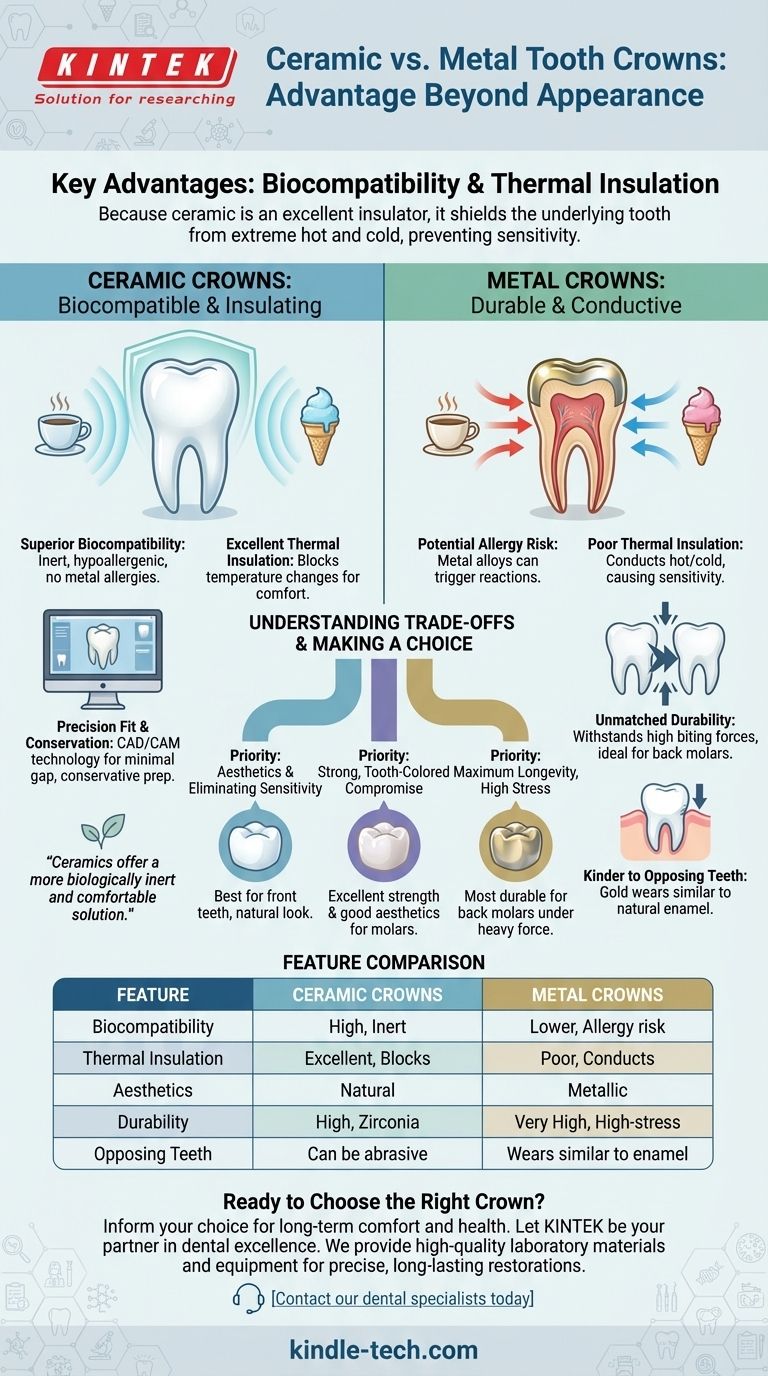

Beyond a natural appearance, another key advantage of using ceramics over metals for tooth crowns is their superior biocompatibility and thermal insulation. Because ceramic is an excellent insulator, it shields the underlying tooth from extreme hot and cold temperatures, preventing the sensitivity and discomfort that can be transmitted through metal crowns.

While aesthetics are the most obvious benefit, the decision between ceramic and metal crowns fundamentally comes down to how the material interacts with your body. Ceramics offer a more biologically inert and comfortable solution by eliminating temperature sensitivity and the risk of metal allergies.

The Functional Advantages of Ceramic Crowns

While a tooth-colored crown is a clear cosmetic improvement, the functional benefits of modern ceramics are what truly set them apart as a premier restorative material.

Superior Biocompatibility

Ceramic materials used in dentistry, such as zirconia and lithium disilicate, are highly biocompatible. This means they are inert and do not cause adverse reactions with the soft tissues of your mouth.

In contrast, some metal alloys, particularly those containing nickel, can trigger allergic reactions in sensitive individuals. Ceramics eliminate this risk entirely.

Excellent Thermal Insulation

Metal is a highly efficient conductor of heat and cold. A metal crown can rapidly transfer the temperature of hot coffee or ice cream to the sensitive dentin and nerve of the tooth underneath, causing a sharp, unpleasant sensation.

Ceramics are thermal insulators, acting as a protective barrier. They effectively block temperature changes, leading to a much more comfortable experience and reducing the risk of nerve irritation over time.

Precision Fit and Conservation of Tooth Structure

Modern all-ceramic crowns are often designed and created using CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology. This allows for an incredibly precise fit, minimizing the gap between the crown and the tooth.

A better seal reduces the risk of bacteria leaking underneath the crown, which can cause secondary decay. Additionally, some modern ceramic materials allow for more conservative tooth preparation, meaning less of your healthy tooth structure needs to be removed.

Understanding the Trade-offs: When Metal is Still a Viable Choice

Objectivity requires acknowledging that metal crowns, particularly full-gold crowns, still hold specific advantages in certain clinical situations.

Unmatched Durability

Metals are malleable and not brittle. They can withstand immense biting forces without fracturing, making them an extremely durable choice for back molars where chewing pressure is greatest.

While modern ceramics like monolithic zirconia are exceptionally strong, gold alloys have a long-standing clinical track record for longevity under extreme stress.

Kinder to Opposing Teeth

A crucial factor in any crown is how it wears against the opposing teeth. Gold has a unique property of wearing down at a rate very similar to that of natural tooth enamel.

This means a gold crown is less likely to cause excessive wear on the tooth it bites against. Some harder ceramic materials, if not properly polished, can be more abrasive to the opposing dentition over many years.

How to Apply This to Your Goal

Your choice of crown material should be a collaborative decision with your dentist, based on the location of the tooth, your bite, and your personal priorities.

- If your primary focus is aesthetics and eliminating sensitivity (especially front teeth): An all-ceramic crown is the superior choice for its natural look and excellent insulation.

- If your primary focus is maximum longevity for a back molar under heavy force: A full-gold crown remains one of the most durable and reliable restorations in dentistry.

- If you are looking for a strong, tooth-colored option for a molar: A monolithic zirconia crown offers an excellent modern compromise, providing both high strength and good aesthetics.

Understanding these core material properties empowers you to have a more productive conversation with your dental professional about your long-term oral health.

Summary Table:

| Feature | Ceramic Crowns | Metal Crowns |

|---|---|---|

| Biocompatibility | High (Inert, hypoallergenic) | Lower (Risk of metal allergies) |

| Thermal Insulation | Excellent (Blocks hot/cold sensations) | Poor (Conducts temperature) |

| Aesthetics | Natural, tooth-colored appearance | Metallic (less aesthetic) |

| Durability | High (Especially monolithic zirconia) | Very High (Ideal for high-stress molars) |

| Impact on Opposing Teeth | Can be abrasive if not polished | Wears down similar to natural enamel |

Ready to Choose the Right Crown for Your Smile?

Understanding the material science behind your dental restoration is key to long-term comfort and health. Whether your priority is eliminating temperature sensitivity with a biocompatible ceramic crown or ensuring maximum durability with a metal alloy, an informed choice is a confident choice.

Let KINTEK be your partner in dental excellence. We specialize in providing high-quality laboratory materials and equipment that support the creation of precise, long-lasting dental restorations. Our products help dental labs achieve the perfect fit and aesthetic finish that both dentists and patients demand.

Have a specific case or material question? Our experts are here to help you select the ideal solutions for your lab's needs.

Contact our dental specialists today to discuss how we can support your next restoration project!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Where are ceramics used in the body? Key Applications in Orthopedics, Dentistry & Bone Repair

- What are some of the important characteristics of sintered ceramics? Achieve High-Performance Material Properties

- What are the properties and applications of silicon carbide ceramics? Solve Extreme Engineering Challenges

- What is the purpose of firing or sintering? To Transform Weak Powder into Strong, Dense Ceramics

- Are crowns made of ceramic? A Guide to the Best Material for Your Smile

- What materials can withstand very high temperature? Refractory Metals, Ceramics & Carbon Composites

- Why can high-porosity High-Entropy Ceramic insulation be synthesized via in-situ reaction? Efficient & Pure Solutions

- What is the process of hot isostatic pressing for making ceramic matrix composites? Achieve Near-Zero Porosity for Superior Performance