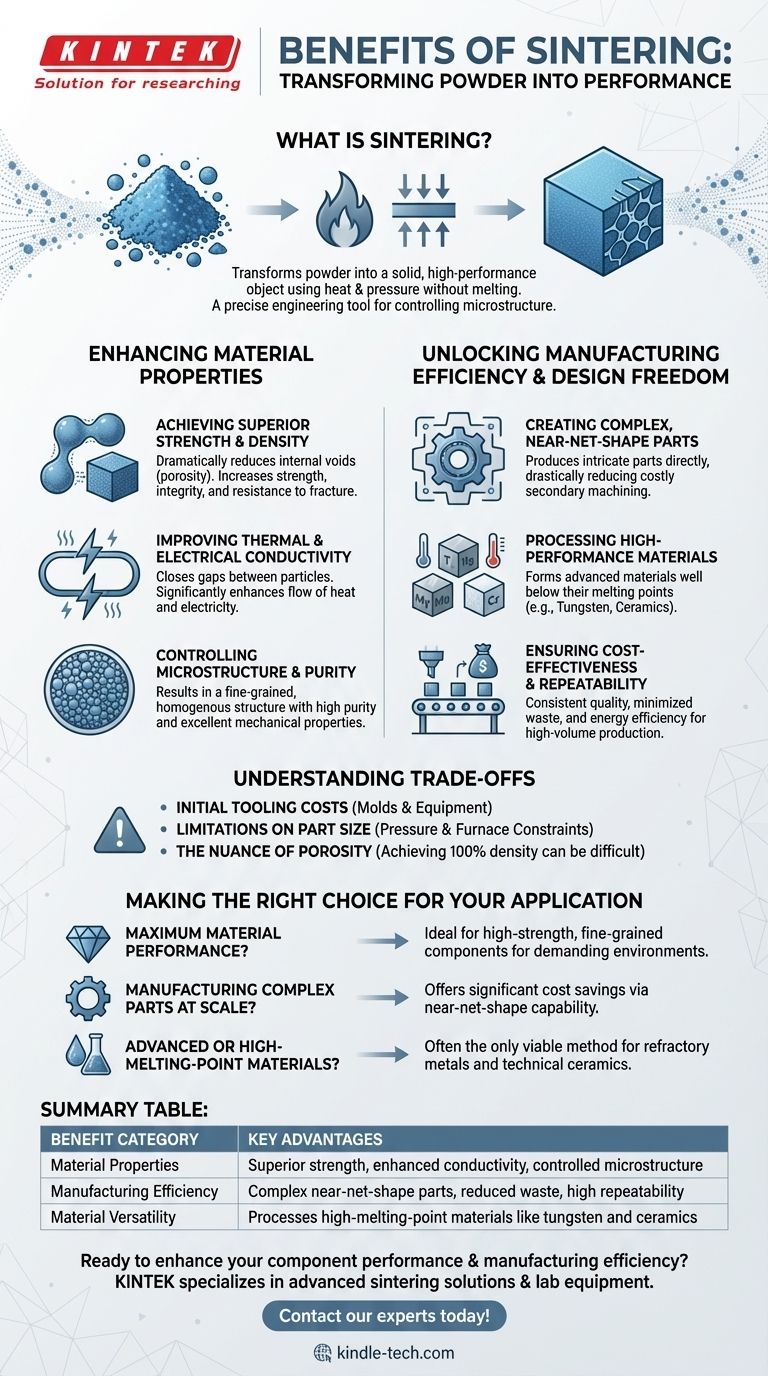

The fundamental benefit of sintering is that it transforms a collection of powder particles into a solid, high-performance object without melting it. This process uses heat and pressure to bond particles together, dramatically increasing material properties like strength and conductivity while enabling the creation of complex parts from materials that are otherwise difficult to work with.

Sintering is not merely a way to solidify a powder; it is a precise engineering tool. Its primary advantage lies in the ability to control a material's final microstructure, achieving a combination of properties, complexity, and cost-efficiency that traditional melting and casting processes often cannot match.

The Core Benefit: Enhancing Material Properties

Sintering fundamentally alters a material's internal structure, leading to significant performance gains. The process works by reducing the empty space, or porosity, between powder particles and creating strong atomic bonds.

Achieving Superior Strength and Density

By fusing particles together, sintering dramatically reduces internal voids. This densification is directly responsible for increasing the material's overall strength, integrity, and resistance to fracture.

Improving Thermal and Electrical Conductivity

Gaps and pores between particles act as insulators, hindering the flow of heat and electricity. Sintering closes these gaps, creating a more continuous path that significantly enhances both thermal and electrical conductivity.

Controlling Microstructure and Purity

Sintering starts with highly uniform powders, allowing for precise control over the final grain size. This results in a fine-grained, homogenous structure with high purity and excellent mechanical properties, as there are no binders or inclusions introduced during the process.

Unlocking Manufacturing Efficiency and Design Freedom

Beyond material enhancement, sintering provides powerful advantages in the manufacturing process itself, offering unique capabilities and economic benefits.

Creating Complex, Near-Net-Shape Parts

Sintering excels at producing intricate and complex parts directly from a mold with high dimensional accuracy. This "near-net-shape" capability drastically reduces or eliminates the need for wasteful and expensive secondary machining.

Processing High-Performance Materials

Many advanced materials, such as tungsten, molybdenum, and certain ceramics, have melting points so high that melting them is impractical or impossible. Sintering allows these materials to be formed into solid parts at temperatures well below their melting point.

Ensuring Cost-Effectiveness and Repeatability

The process is highly repeatable, ensuring consistent quality from part to part. By minimizing material waste and often requiring less energy than melting, sintering can be a highly cost-effective and environmentally friendly option for low- to high-volume production.

Understanding the Trade-offs

While powerful, sintering is not the ideal solution for every application. Understanding its limitations is critical for making an informed decision.

Initial Tooling and Material Costs

The production of fine, uniform metal or ceramic powders can be expensive. Furthermore, the dies and presses used to form the initial "green" parts can represent a significant upfront investment, particularly for complex designs.

Limitations on Part Size

The pressure required for initial compaction and the size of sintering furnaces can place practical limits on the maximum dimensions of a part. Producing very large components via sintering can be challenging and costly.

The Nuance of Porosity

While sintering is excellent at reducing porosity, achieving 100% of a material's theoretical density can be difficult without advanced techniques like hot pressing. In some cases, residual porosity can remain, which may be undesirable for certain high-stress applications.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your project's primary goals.

- If your primary focus is maximum material performance: Sintering provides unparalleled control over microstructure, making it ideal for creating high-strength, fine-grained components for demanding environments.

- If your primary focus is manufacturing complex parts at scale: The near-net-shape capability of sintering offers significant cost savings by minimizing material waste and post-processing steps.

- If your primary focus is working with advanced or high-melting-point materials: Sintering is often the only viable method for creating solid parts from materials like refractory metals and technical ceramics.

Ultimately, choosing sintering is a decision to prioritize precise material engineering and manufacturing efficiency for demanding applications.

Summary Table:

| Benefit Category | Key Advantages |

|---|---|

| Material Properties | Superior strength, enhanced thermal/electrical conductivity, controlled microstructure |

| Manufacturing Efficiency | Complex near-net-shape parts, reduced waste, high repeatability |

| Material Versatility | Processes high-melting-point materials like tungsten and ceramics |

Ready to enhance your component performance and manufacturing efficiency? KINTEK specializes in providing advanced sintering solutions and lab equipment for creating high-strength, complex parts from metal and ceramic powders. Our expertise helps you achieve precise material control and cost-effective production. Contact our experts today to discuss how sintering can benefit your specific application!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What is the temperature of sintering zirconia? Mastering the Protocol for Perfect Dental Restorations

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is a dental oven? The Precision Furnace for Creating Strong, Aesthetic Dental Restorations