In essence, blue PVD is not a paint or a dye, but a highly durable surface coating created by bonding a thin ceramic layer to an object in a high-tech vacuum chamber. This process, known as Physical Vapor Deposition (PVD), produces a vibrant blue finish that is integral to the surface itself, offering significant improvements in wear and corrosion resistance.

The core concept to understand is that PVD is a manufacturing process, not just a color. It uses a vaporized solid material to create a thin, protective film, and the "blue" is a specific outcome of that process, valued for both its aesthetic appeal and its functional toughness.

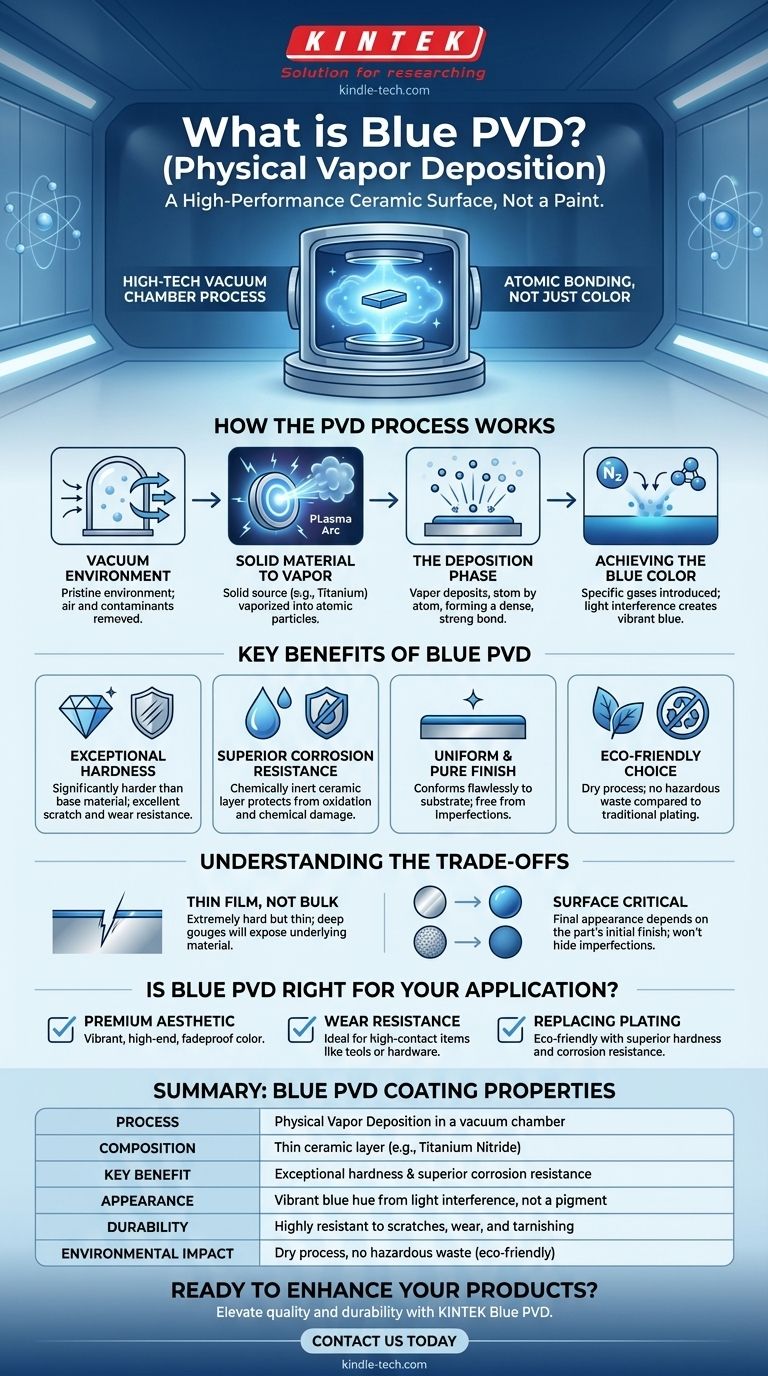

How the PVD Process Works

Physical Vapor Deposition is a sophisticated technique that fundamentally alters a material's surface properties. The entire process takes place inside a sealed vacuum chamber to ensure absolute purity.

The Vacuum Environment

First, the component to be coated is placed in a vacuum chamber. All the air is pumped out to create a pristine environment, free from contaminants that could interfere with the coating's adhesion and uniformity.

From Solid Material to Vapor

A solid source material, often a metal like titanium or zirconium, is then vaporized using heat or a high-energy plasma. This turns the solid material into a cloud of atomic particles.

The Deposition Phase

This vaporized material is then deposited, atom by atom, onto the surface of the component. It forms an extremely strong molecular bond with the substrate, creating a dense, hard, and uniform thin film.

Achieving the Blue Color

The blue color is not a pigment. It is achieved by precisely introducing specific reactive gases (like nitrogen) during the deposition phase. The resulting ceramic compound (e.g., titanium nitride) and the exact thickness of the film determine how it reflects light, producing the characteristic blue hue.

Key Benefits of Blue PVD

Compared to traditional coating methods like electroplating or painting, PVD offers a distinct set of advantages that make it a preferred choice for high-performance applications.

Exceptional Hardness

PVD coatings are significantly harder than the base material they cover and much more durable than most other coating types. This provides excellent resistance to scratches and daily wear.

Superior Corrosion Resistance

The deposited ceramic layer is chemically inert, forming an effective barrier that protects the underlying material from oxidation, tarnishing, and damage from common chemicals.

Uniform and Pure Finish

Because the coating is applied in a vacuum at an atomic level, it perfectly conforms to the underlying surface. The finish is exceptionally pure and free of the imperfections that can occur with wet application processes.

An Environmentally Friendly Choice

PVD is a dry process that produces no hazardous waste, making it a much more environmentally responsible alternative to traditional electrochemical processes like chrome plating.

Understanding the Trade-offs

While powerful, the PVD process has characteristics that are important to understand to set the right expectations.

It's a Thin Film, Not a Bulk Material

The PVD coating is extremely hard but also very thin. A deep gouge or scratch that penetrates the coating will expose the substrate material underneath. It enhances surface properties but does not change the core material.

The Underlying Surface is Critical

The final appearance of a PVD coating is directly dependent on the finish of the part it covers. A polished surface will result in a glossy blue finish, while a brushed or bead-blasted surface will produce a matte blue. The PVD process will not hide existing scratches or imperfections.

Is Blue PVD the Right Choice for Your Application?

Choosing this finish depends entirely on your project's goals.

- If your primary focus is a premium aesthetic: Blue PVD provides a vibrant, high-end color that is far more durable and resistant to fading than paint or anodizing.

- If your primary focus is wear resistance: The coating significantly increases surface hardness, making it ideal for high-contact items like watch cases, tools, or decorative hardware.

- If you are replacing traditional plating: PVD offers a more environmentally friendly process with superior performance in hardness and corrosion resistance.

Ultimately, blue PVD is a sophisticated finishing technology that merges advanced material science with high-end aesthetics.

Summary Table:

| Property | Blue PVD Coating |

|---|---|

| Process | Physical Vapor Deposition in a vacuum chamber |

| Composition | Thin ceramic layer (e.g., Titanium Nitride) |

| Key Benefit | Exceptional hardness & superior corrosion resistance |

| Appearance | Vibrant blue hue from light interference, not a pigment |

| Durability | Highly resistant to scratches, wear, and tarnishing |

| Environmental Impact | Dry process, no hazardous waste (eco-friendly) |

Ready to enhance your products with a durable, high-performance finish?

Blue PVD coating from KINTEK offers a premium aesthetic and superior functional toughness that outperforms traditional plating and painting. Whether you're manufacturing watches, tools, medical devices, or decorative hardware, our expertise in lab equipment and surface coating technologies ensures a flawless, durable finish tailored to your specifications.

Contact us today to discuss how KINTEK's solutions can elevate your product's quality and durability. Get in touch with our experts now!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating worth it? Maximize Component Life and Performance

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance