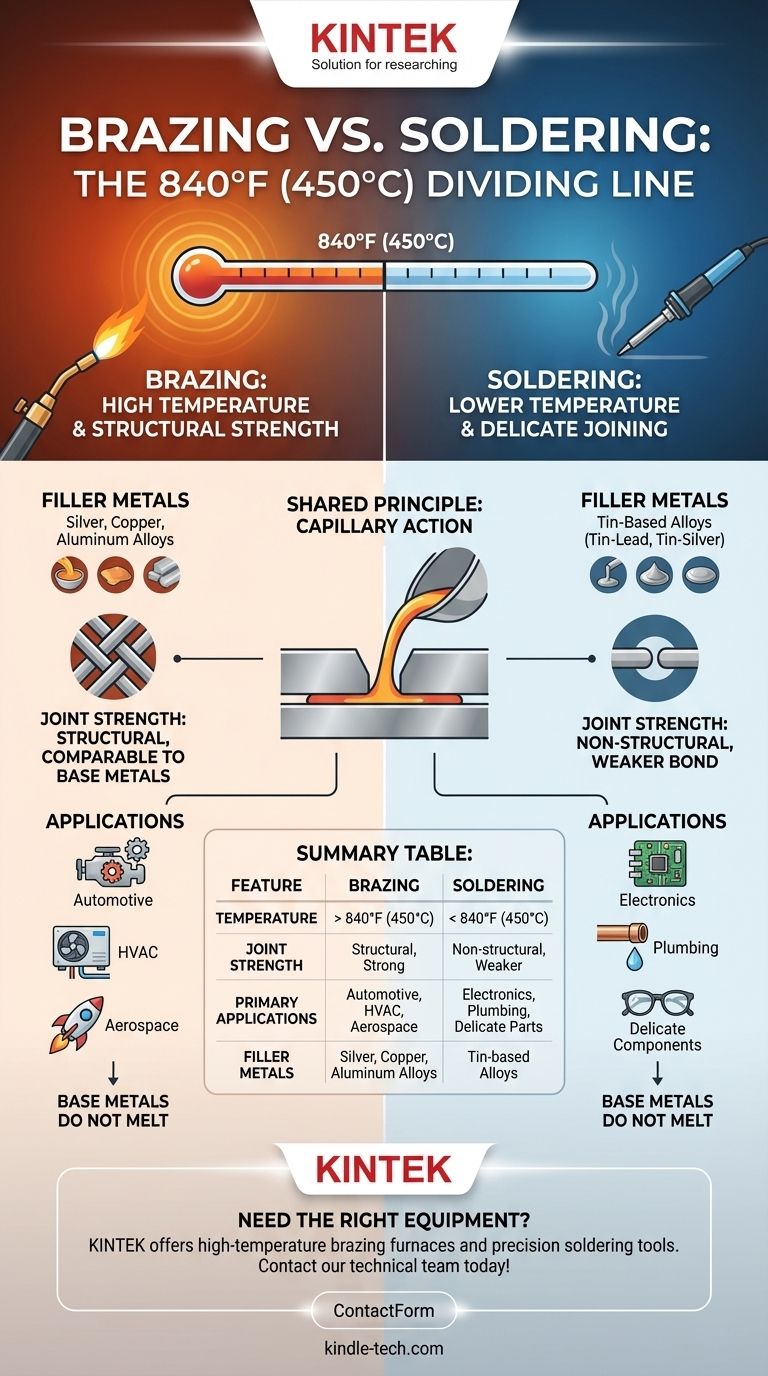

At its core, the difference between brazing and soldering is the temperature at which the process occurs. Brazing uses a filler metal that melts at a temperature above 840°F (450°C), while soldering uses a filler metal that melts below that threshold. This fundamental difference in temperature dictates the strength of the final joint and the appropriate applications for each method.

The choice between brazing and soldering is not just a matter of heat; it's a decision between creating a weaker, surface-level bond (soldering) and forming a powerful, structural connection that is often as strong as the metals being joined (brazing).

The Defining Factor: Temperature and Filler Metal

The single, universally accepted distinction between these two processes is the melting point of the filler material used to join the base metals.

The 840°F (450°C) Dividing Line

This specific temperature is the industry standard that separates the two techniques. Any joining process using a filler metal that melts below this point is classified as soldering. Any process using a filler that melts above it is brazing.

Soldering: Lower Temperature, Softer Metals

Soldering employs filler metals, or solders, that are typically tin-based alloys (like tin-lead or tin-silver). These alloys have low melting points, making the process suitable for delicate components that cannot withstand high heat.

Brazing: Higher Temperature, Stronger Alloys

Brazing uses filler alloys with much higher melting points, often containing silver, copper, or aluminum. Crucially, in both brazing and soldering, the filler metal's melting point is always lower than that of the base metals being joined; the base metals themselves never melt.

How Temperature Translates to Performance

The difference in heat and filler material has a direct and significant impact on the strength and characteristics of the finished joint.

Joint Strength: The Critical Difference

This is the most important practical distinction. A brazed joint creates a strong metallurgical bond that is often as strong as or stronger than the base materials. It is a structural joining method.

A soldered joint is significantly weaker. It is typically used for applications where mechanical strength is not the primary requirement, such as creating electrical connections or low-pressure seals.

The Role of Capillary Action

Both processes rely on capillary action to draw the molten filler metal into the tight-fitting space between the base components. This ensures a complete, uniform bond across the entire joint surface.

Impact on Base Materials

The higher temperatures required for brazing can potentially alter the properties of the base metals, such as their temper or hardness. This must be considered during the design phase. Soldering's lower heat poses a much smaller risk to the components being joined.

Understanding the Trade-offs

Choosing the right method requires weighing the need for strength against the complexity and cost of the process.

Why Not Always Braze for Strength?

Brazing requires significantly more heat, which translates to higher energy costs and more sophisticated equipment, such as torches or furnaces. The high temperatures also increase the risk of oxidation, which can require protective atmospheres (like in vacuum brazing) to ensure a clean, strong joint.

When Soldering is the Superior Choice

Soldering is ideal for joining heat-sensitive components, most notably in electronics. The process is faster, requires less energy, and can be performed with simpler, less expensive tools like a soldering iron.

Consistency and Complexity

Brazing excels at creating highly consistent joints, even in complex geometries. This makes it a preferred method in mass production for industries like automotive and HVAC, where part-to-part reliability is essential.

Making the Right Choice for Your Application

Ultimately, the correct process depends entirely on the demands of the final product.

- If your primary focus is structural strength and durability: Brazing is the correct choice, as it creates a bond comparable in strength to the base metals.

- If your primary focus is joining heat-sensitive electronics: Soldering is the only viable option due to its low-temperature application.

- If your primary focus is a simple, low-pressure seal (like in copper plumbing): Soldering provides a sufficient bond and is more cost-effective and easier to perform.

- If your primary focus is joining dissimilar metals for a high-strength bond: Brazing is an excellent method for creating strong joints between different types of metals.

Select your joining method based on the mechanical strength your assembly truly requires.

Summary Table:

| Feature | Brazing | Soldering |

|---|---|---|

| Temperature | Above 840°F (450°C) | Below 840°F (450°C) |

| Joint Strength | Structural, as strong as base metals | Non-structural, weaker bond |

| Primary Applications | Automotive, HVAC, aerospace | Electronics, plumbing, delicate components |

| Filler Metals | Silver, copper, aluminum alloys | Tin-based alloys (tin-lead, tin-silver) |

Need the Right Equipment for Your Joining Process?

Whether you require high-temperature brazing furnaces or precision soldering tools, KINTEK has the laboratory equipment and consumables to ensure perfect results. Our experts can help you select the ideal solution for your specific application, whether you're working with structural components or delicate electronics.

Contact our technical team today to discuss how KINTEK's specialized lab equipment can enhance your metal joining processes and deliver reliable, consistent performance.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

People Also Ask

- What hazard is involved when using a furnace? Protect Your Home from the Silent Killer

- What is the temperature limit on a muffle furnace? A Guide to Selecting the Right Model

- At what temperature is it safe to open a muffle furnace? A Guide to Preventing Injury and Equipment Damage

- What affects the melting point of a substance? Uncover the Key Factors & Forces

- Does melting point ever change? Unlock the Secrets of Pressure and Purity