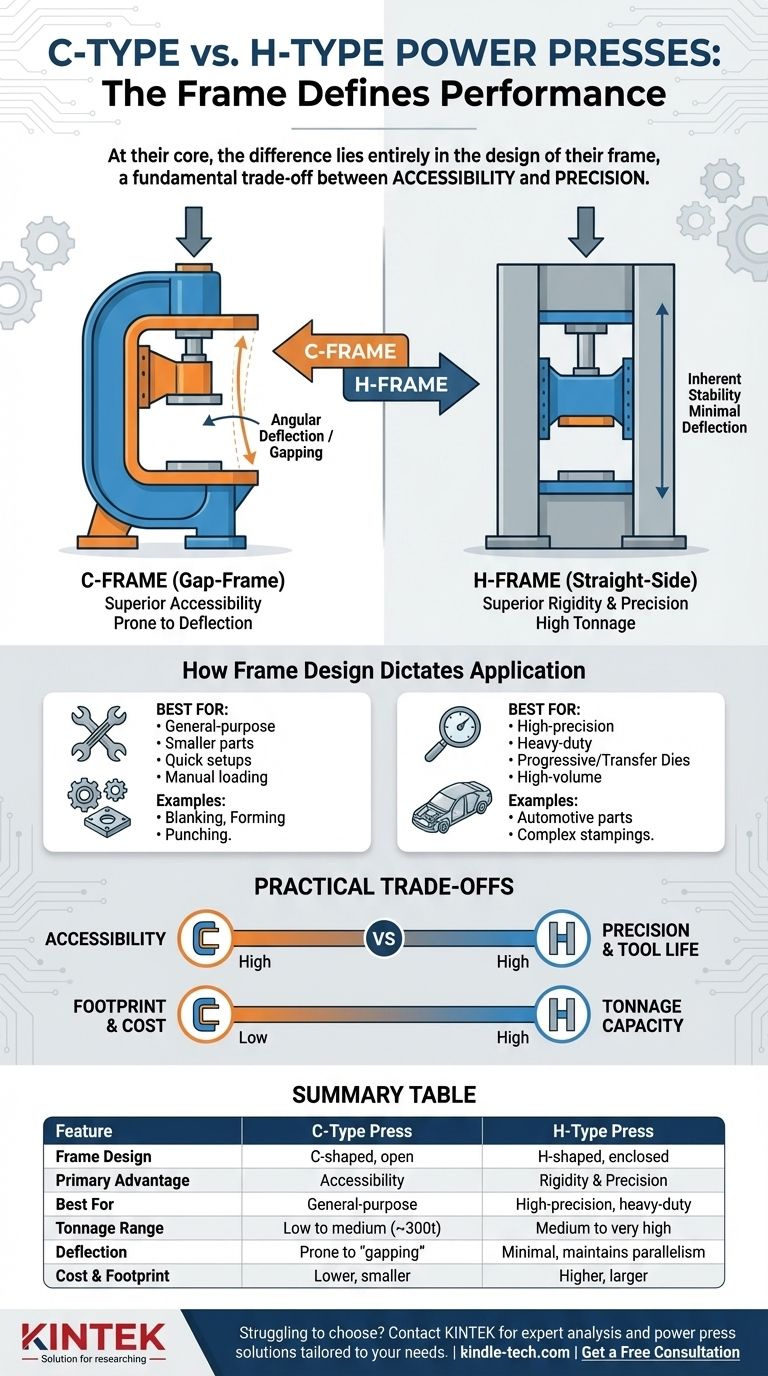

At their core, the difference between a C-type and an H-type power press lies entirely in the design of their frame. A C-type press, also known as a C-frame or gap-frame press, features a frame shaped like the letter 'C', providing open access on three sides. In contrast, an H-type press, often called an H-frame or straight-side press, has a more robust, fully supported frame with two straight side columns, resembling the letter 'H'.

The choice between a C-frame and an H-frame press is a fundamental trade-off between accessibility and precision. C-frame presses offer superior access for tooling and part handling, while H-frame presses deliver superior rigidity and accuracy under heavy loads.

The Defining Factor: Frame Rigidity and Deflection

The shape of the press frame is not merely an aesthetic choice; it dictates how the machine handles the immense forces generated during a stamping operation. This directly impacts the precision of the final part.

The "Gapping" Effect in C-Frame Presses

The C-shape, by its nature, has an open "throat." When the press applies force, the frame has a tendency to deflect or "yawn" open slightly.

This phenomenon, known as angular deflection or gapping, can cause misalignment between the upper and lower halves of the die. While minimal, this deflection can be a critical factor in high-precision applications.

The Inherent Stability of the H-Frame Design

An H-frame press functions like a complete box. The stamping forces are contained vertically between the bed, the crown, and the two massive side columns.

This closed structure is inherently more rigid and resistant to deflection. It ensures the ram remains parallel to the bed even under maximum tonnage, which is crucial for complex operations.

How Frame Design Dictates Application

The structural differences between the two press types make them suitable for very different manufacturing tasks. Understanding your application's needs is key to choosing the correct machine.

When to Choose a C-Frame Press

The primary advantage of the C-frame is its accessibility. With open access on the front and both sides, it is ideal for manual part loading, quick die changes, and feeding material from the side.

These presses excel in general-purpose, single-station operations like blanking, forming, and punching smaller parts where extreme precision is not the primary concern.

When to Choose an H-Frame Press

The superior rigidity of the H-frame makes it the standard for high-precision applications. It is the preferred choice for running large, heavy, or complex progressive and transfer dies.

Because H-frames minimize deflection, they produce more consistent parts and significantly extend the life of expensive tooling by preventing uneven wear. They are essential for high-volume production and heavy-tonnage applications, such as those found in the automotive industry.

Understanding the Practical Trade-offs

Choosing a press involves balancing performance requirements with practical constraints like cost and floor space.

Accessibility vs. Tool Life

The excellent access of a C-frame can come at a cost. If the load is not perfectly centered in the die, the gapping effect is amplified, leading to uneven die wear and a shorter tool lifespan.

An H-frame’s restricted access (typically front and back only) can make setups more time-consuming, but its stability protects the tooling investment over millions of cycles.

Footprint and Cost

For a given tonnage, a C-frame press is generally less expensive and has a smaller footprint than an H-frame press. This makes it an economical choice for job shops and smaller-scale production.

H-frame presses are a larger capital investment, requiring more floor space and more robust foundations to support their significant weight.

Tonnage Limitations

C-frame presses are most common in lower to medium tonnage ranges, typically up to around 300 tons. Beyond this, managing frame deflection becomes impractical.

Virtually all high-tonnage applications rely on the structural integrity of the H-frame design to handle the immense forces safely and accurately.

Making the Right Choice for Your Goal

Your specific application will determine the right press. The decision comes down to a clear evaluation of your priorities.

- If your primary focus is versatility and quick setups for smaller parts: A C-frame press is the most practical and cost-effective choice.

- If your primary focus is high-precision stamping or running large progressive dies: The rigidity and stability of an H-frame press are non-negotiable for ensuring part quality and maximizing tool life.

- If you are dealing with very high tonnage requirements: Your application almost certainly demands the structural integrity of an H-frame press.

Understanding this core distinction between frame design is the first and most critical step in selecting the right machine for your manufacturing needs.

Summary Table:

| Feature | C-Type Press (Gap-Frame) | H-Type Press (Straight-Side) |

|---|---|---|

| Frame Design | C-shaped, open on three sides | H-shaped, fully enclosed box structure |

| Primary Advantage | Superior accessibility for tooling/parts | Superior rigidity and precision |

| Best For | General-purpose stamping, smaller parts, quick setups | High-precision, heavy-duty, and progressive die applications |

| Typical Tonnage Range | Low to medium (up to ~300 tons) | Medium to very high |

| Deflection | Prone to angular deflection ("gapping") under load | Minimal deflection, maintains ram parallelism |

| Cost & Footprint | Lower cost, smaller footprint | Higher cost, larger footprint |

Struggling to choose the right press for your production line? The decision between a C-frame and an H-frame press is critical for achieving your quality, precision, and throughput goals. At KINTEK, we specialize in providing robust laboratory and industrial equipment, including power presses tailored to your specific needs. Our experts can help you analyze your application to ensure you select a machine that maximizes your efficiency and protects your tooling investment.

Contact us today to discuss your requirements and discover the perfect press solution for your laboratory or manufacturing facility.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What is the function of a laboratory hydraulic press and a 15 mm circular mold? Create Dense Oxygen Membrane Green Bodies

- What is the alternative to XRF? Choose the Right Elemental Analysis for Your Lab

- What is the principle of forging press? Achieve Superior Strength with Controlled Metal Deformation

- What materials are in a hydraulic press? Key Components for High-Power Applications

- How is a hydraulic press utilized in the assembly of all-solid-state battery anodes? Optimize Indium Foil Interfaces

- What are the disadvantages of a hydraulic press? Low Speed, High Maintenance & Energy Costs

- How many pounds of force can a hydraulic press produce? From 10,000 to 80,000+ Tons Explained

- What is the limitation of XRF? Understanding the Key Constraints for Accurate Analysis