At its core, Chemical Vapor Deposition (CVD) is a process used to create high-quality, solid thin films on a substrate from a gaseous source. The "atmospheric pressure" variant, known as APCVD, performs this process in a chamber at normal ambient pressure, eliminating the need for expensive and complex vacuum systems. The entire process relies on a chemical reaction on a heated surface to deposit the desired material.

The central concept to grasp is that APCVD is a versatile and often high-speed method for film deposition. Its primary trade-off is sacrificing the ultra-high purity of vacuum-based methods for the significant benefits of simpler equipment, lower cost, and faster production rates.

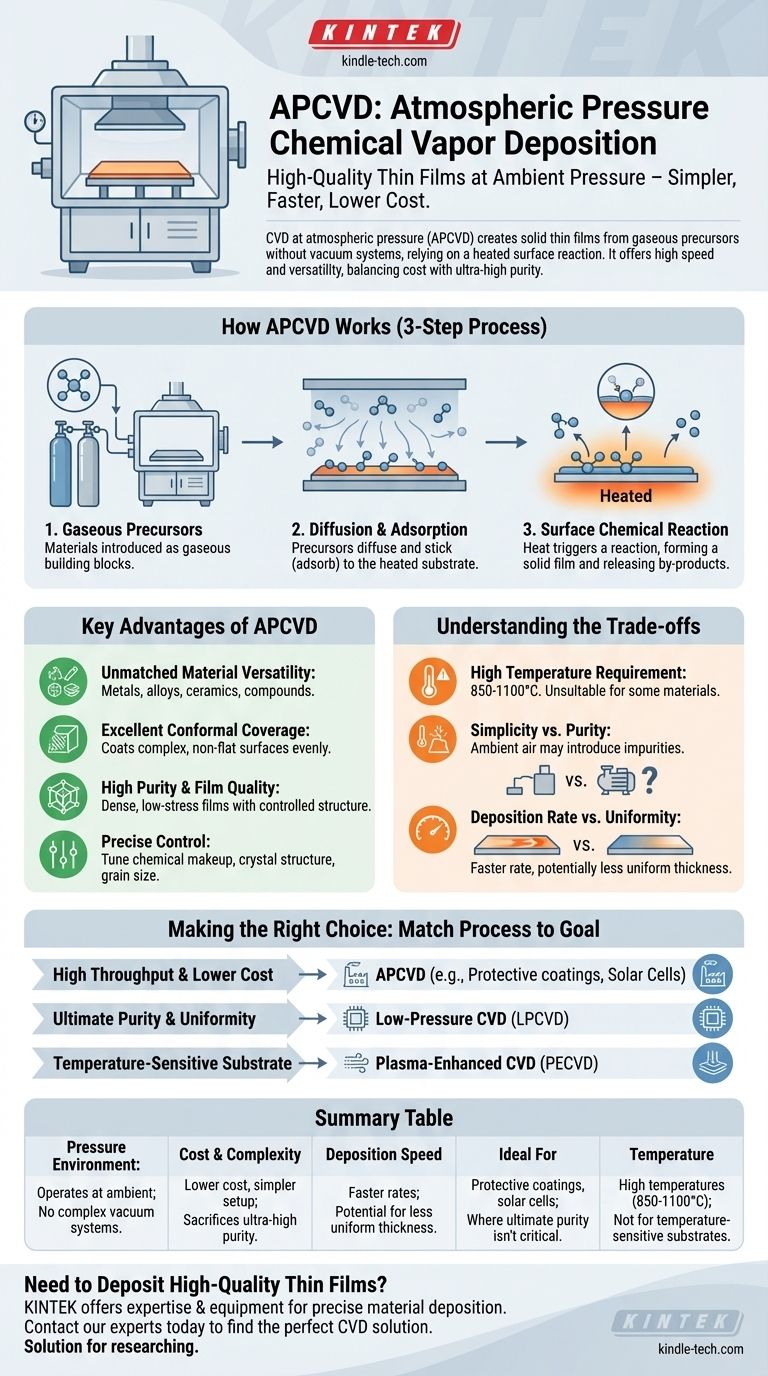

How the CVD Process Fundamentally Works

To understand APCVD, we must first understand the foundational steps of any CVD process. The entire operation can be broken down into three critical stages that occur in sequence on a microscopic level.

The Gaseous Precursors

First, all the materials that will form the final film are introduced into a reaction chamber as gases, known as precursors. These gases are the building blocks of the final coating.

Diffusion and Adsorption

The precursor gases then diffuse through the chamber and spread across the surface of the target object, or substrate. Once there, the gas molecules physically stick to the heated substrate in a process called adsorption.

The Surface Chemical Reaction

This is the crucial step. The heat of the substrate provides the energy needed to trigger a chemical reaction or decomposition of the adsorbed gas molecules. This reaction forms a solid, dense film of the desired material on the substrate and releases other gaseous by-products, which are then carried away.

The Key Advantages of Chemical Vapor Deposition

CVD, including its atmospheric pressure variant, is a widely used industrial process because of its powerful capabilities. It offers a degree of control and versatility that is difficult to achieve with other methods.

Unmatched Material Versatility

The process is not limited to one type of material. It can be used to deposit a vast range of films, including metals, multi-component alloys, and complex ceramic or compound layers.

Excellent Conformal Coverage

Because the deposition happens from a gas phase, the film can form evenly over complex, non-flat surfaces. This "wrap-around" capability is crucial for coating intricate components.

High Purity and Film Quality

CVD films are known for their high purity, good denseness, and low residual stress. By carefully controlling the process, it's possible to produce films with excellent crystallization and structure.

Precise Control Over Film Properties

Technicians can finely tune the outcome. By adjusting parameters like temperature, gas flow, and composition, one can precisely control the chemical makeup, crystal structure, and grain size of the final coating.

Understanding the Trade-offs of APCVD

While powerful, the process is not without its limitations. Understanding these trade-offs is key to determining if it is the right choice for a given application.

The High Temperature Requirement

A significant limitation of traditional CVD is the high reaction temperature, which is often between 850-1100°C. Many substrate materials, such as certain plastics or lower-melting-point metals, cannot withstand this heat.

Simplicity vs. Purity

Operating at atmospheric pressure means the equipment is far simpler and cheaper, as it avoids the need for a high-vacuum environment. However, the presence of ambient air (nitrogen, oxygen, etc.) in the chamber can introduce impurities into the film, which may be unacceptable for highly sensitive applications like advanced semiconductors.

Deposition Rate vs. Uniformity

The higher concentration of precursor gases at atmospheric pressure typically leads to a faster deposition rate, which is excellent for high-throughput manufacturing. The downside is that this can sometimes lead to less uniform film thickness compared to the more controlled, slower deposition in a low-pressure environment.

Making the Right Choice for Your Goal

Selecting the correct deposition method requires matching the process capabilities to your project's most critical outcome.

- If your primary focus is high throughput and lower cost: APCVD is an excellent choice for applications where ultimate purity is not the primary concern, such as protective coatings or solar cell manufacturing.

- If your primary focus is ultimate film purity and uniformity: You should consider a vacuum-based method like Low-Pressure CVD (LPCVD), which offers superior control over contaminants and film consistency.

- If your substrate is temperature-sensitive: Standard high-temperature APCVD is unsuitable. In this case, you must explore lower-temperature alternatives like Plasma-Enhanced CVD (PECVD).

Understanding these core principles allows you to select the right deposition technology for your specific material and application needs.

Summary Table:

| Aspect | APCVD Advantage | Consideration |

|---|---|---|

| Pressure Environment | Operates at ambient pressure | No need for complex vacuum systems |

| Cost & Complexity | Lower equipment cost and simpler setup | Sacrifices ultra-high purity of vacuum methods |

| Deposition Speed | Faster deposition rates | Potential for less uniform thickness |

| Ideal For | Protective coatings, solar cells | Applications where ultimate purity isn't critical |

| Temperature | High temperatures (850-1100°C) required | Not suitable for temperature-sensitive substrates |

Need to Deposit High-Quality Thin Films?

Choosing the right Chemical Vapor Deposition method is critical for your project's success. Whether your priority is high-throughput production with APCVD or the ultimate purity of low-pressure systems, KINTEK has the expertise and equipment to meet your laboratory's specific needs.

Let's discuss your application. We specialize in providing lab equipment and consumables for precise material deposition.

Contact our experts today to find the perfect CVD solution for your research or production goals.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity