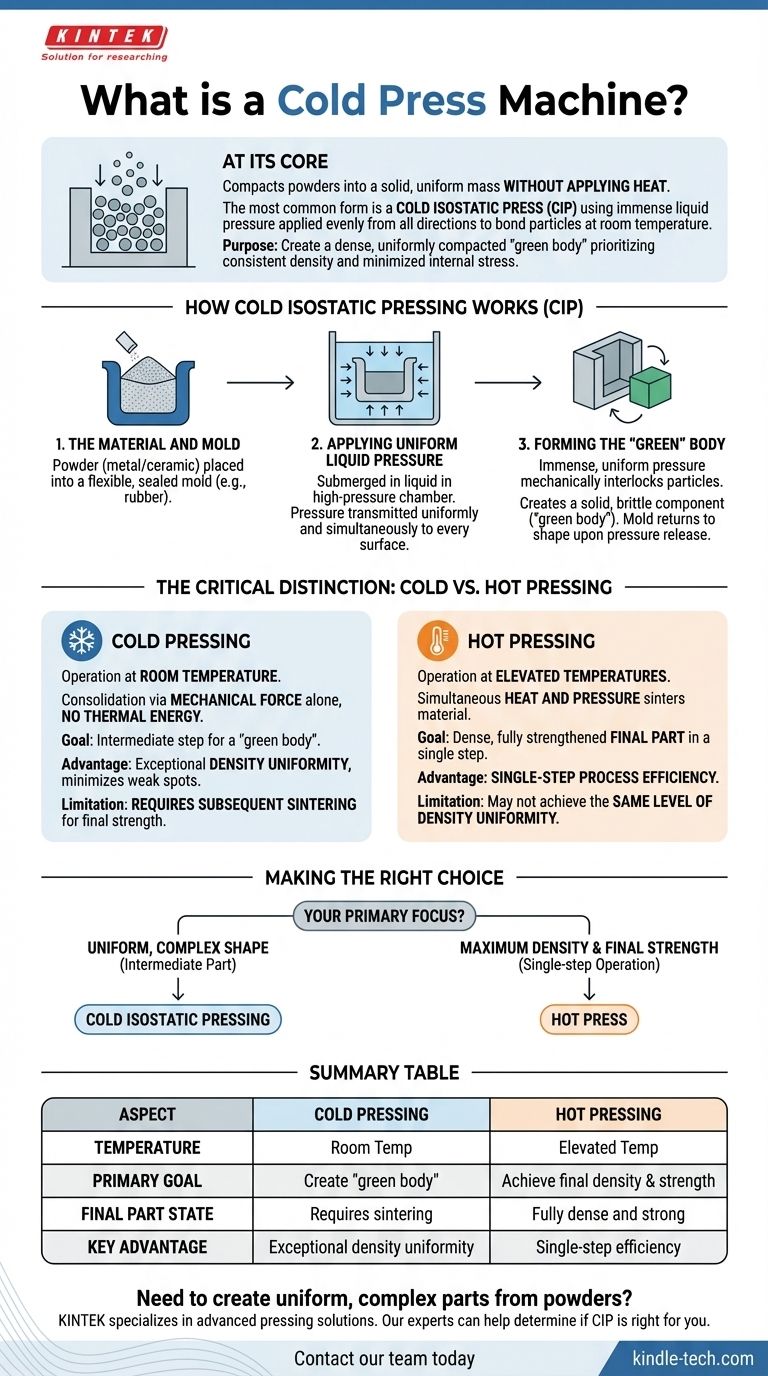

At its core, a cold press machine is a device used to compact powders into a solid, uniform mass without applying heat. The most common form is a cold isostatic press, which uses immense liquid pressure applied evenly from all directions to mechanically bond the powder particles together at room temperature.

The fundamental purpose of cold pressing is to create a dense, uniformly compacted component—often called a "green body"—from a powder. This method prioritizes consistent density and minimized internal stress over achieving final strength in a single step.

How Cold Isostatic Pressing Works

Cold isostatic pressing (CIP) is a precise and effective method for forming complex shapes from powders. The process is defined by its use of a liquid medium to transmit pressure.

The Material and Mold

First, the powdered material, often a metal or ceramic, is placed into a flexible, sealed mold. This mold is typically made from an elastomer like rubber, which has a low resistance to deformation.

Applying Uniform Liquid Pressure

The sealed mold is then submerged in a liquid inside a high-pressure chamber. The liquid is pressurized, transmitting that force uniformly and simultaneously to every surface of the mold.

Imagine squeezing a stress ball submerged in water—the pressure comes from all directions at once. This is the principle behind isostatic pressing.

Forming the "Green" Body

This immense, uniform pressure forces the powder particles into close contact, mechanically interlocking them. This creates a solid, albeit brittle, component known as a green body.

Once the pressure is released, the liquid is drained, and the flexible mold returns to its original shape, allowing for easy removal of the newly formed part.

The Critical Distinction: Cold vs. Hot Pressing

The term "cold" is the defining characteristic of this process and sets it apart from other common industrial pressing methods.

Operation at Room Temperature

Cold pressing occurs entirely at ambient or room temperature. The consolidation of the powder is achieved through mechanical force alone, not thermal energy.

The Contrast with Hot Pressing

Hot press machines, by contrast, combine high pressure with elevated temperatures. This simultaneous application of heat and pressure sinters the material, creating a dense, fully strengthened part in a single operation.

The goal of hot pressing is often to achieve the final desired density and mechanical properties in one step, whereas cold pressing is an intermediate step.

Understanding the Trade-offs

Choosing between cold and hot pressing involves understanding the distinct advantages and limitations of each method, which are centered on the role of heat.

Advantage of Cold Pressing: Uniformity

Because pressure is applied isostatically (equally from all directions), cold pressing produces parts with exceptionally uniform density. This minimizes weak spots and internal stresses, which is critical for high-performance components.

Limitation of Cold Pressing: The "Green" State

A part made through cold pressing is not in its final form. This "green body" has the right shape and density but lacks significant strength. It must undergo a subsequent process, like sintering (heating without melting), to achieve its final mechanical properties.

When to Choose Hot Pressing

Hot pressing is chosen when the goal is to produce a fully dense and strong part in a single, streamlined process. However, it may not achieve the same level of density uniformity as a cold-pressed and subsequently sintered part.

Making the Right Choice for Your Goal

The decision to use a cold or hot press depends entirely on the requirements of the final component and the manufacturing process.

- If your primary focus is creating a complex shape with highly uniform density before a final strengthening step: Cold isostatic pressing is the ideal method.

- If your primary focus is achieving maximum density and final mechanical properties in a single, efficient operation: A hot press is the more direct solution.

Ultimately, your choice is guided by whether the priority is the perfect uniformity of an intermediate part or the single-step efficiency of producing a finished one.

Summary Table:

| Aspect | Cold Pressing | Hot Pressing |

|---|---|---|

| Temperature | Room Temperature | Elevated Temperature |

| Primary Goal | Create a uniform "green body" | Achieve final density & strength |

| Final Part State | Requires sintering for strength | Fully dense and strong part |

| Key Advantage | Exceptional density uniformity | Single-step process efficiency |

Need to create uniform, complex parts from powders? KINTEK specializes in lab equipment and consumables, including advanced pressing solutions. Our experts can help you determine if a cold isostatic press is the right choice for your materials and application. Contact our team today to discuss your specific laboratory needs and achieve superior compaction results.

Visual Guide

Related Products

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Vacuum Cold Mounting Machine for Sample Preparation

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What is the benefit of using a cold isostatic press for the secondary treatment of TiC10/Cu-Al2O3? Boost Density Now!

- What will happen if forging is carried out at very low temperature? Discover the Power of Cold Forging

- Why is a cold isostatic press (CIP) required after uniaxial pressing? Maximize LLZO Density & Performance

- What types of materials are used for canisters in the HIP process? Optimized Choices for Material Densification

- What are the disadvantages of cold isostatic pressing? Key Limitations in Dimensional Accuracy & Speed

- What is cold sintering? A Low-Energy Path to Novel Composite Materials

- What are the examples of cold working metals? Key Processes for Stronger, Precision Parts

- Why is a Cold Isostatic Press (CIP) Required for LLZTBO? Enhance Density and Structural Integrity