In modern hydraulics, "high pressure" generally refers to systems operating from 3,000 PSI up to around 6,000 PSI (210 to 420 bar). However, the term is highly relative; what is considered high pressure for one application may be standard for another. The most accurate definition depends entirely on the context of the industry and the specific equipment involved.

The concept of "high pressure" is a moving target that has evolved with technology. Instead of a single number, it's more useful to think in terms of pressure ranges, as each range corresponds to different design principles, component requirements, and safety considerations.

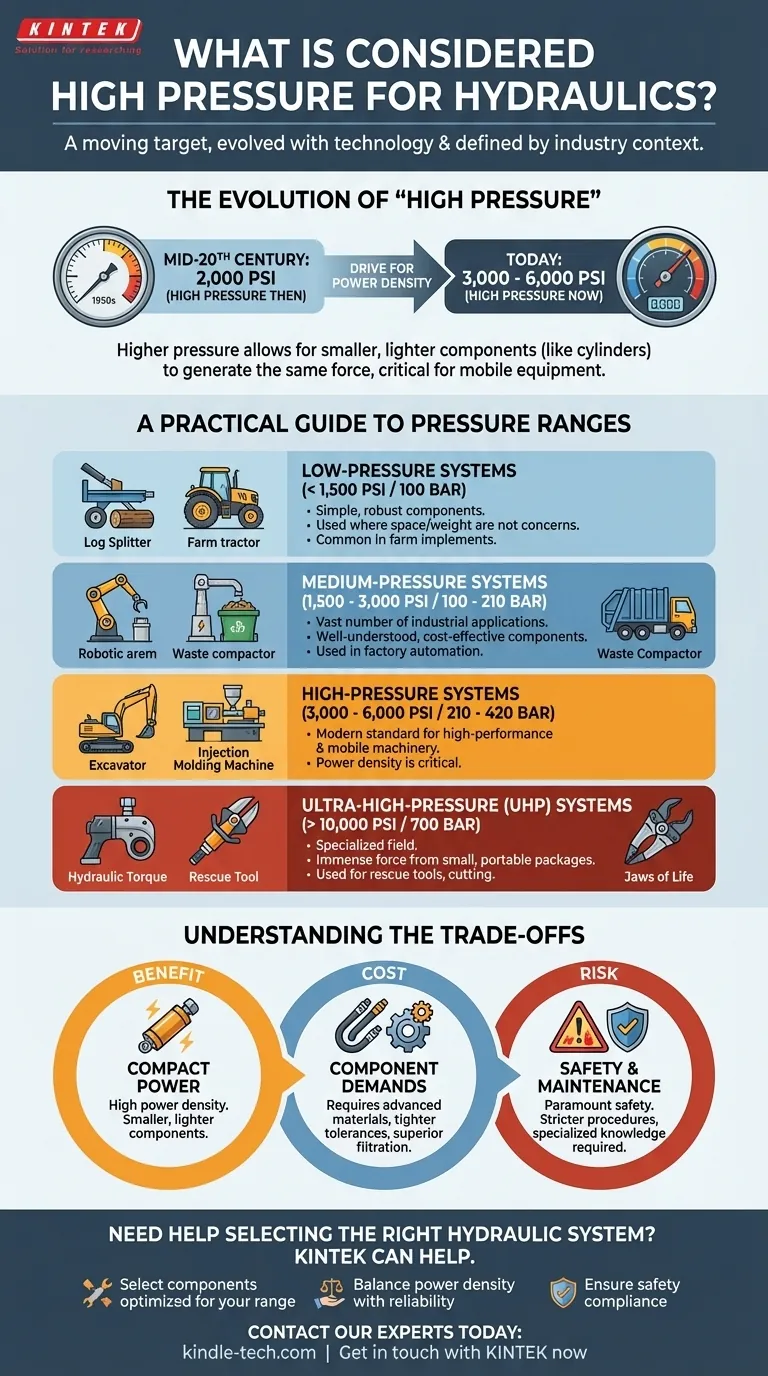

The Evolution of "High Pressure"

The definition of high pressure has changed significantly over the decades. As material science, sealing technology, and manufacturing precision have advanced, the operational pressures of standard hydraulic systems have consistently increased.

A Shifting Standard

In the mid-20th century, a 2,000 PSI system was considered high pressure. Today, that is often seen as a medium-pressure workhorse for many standard industrial applications.

The Drive for Power Density

The primary driver for increasing pressure is power density. Higher pressure allows for the same amount of force to be generated by smaller, lighter components like cylinders and motors. This is especially critical in mobile equipment like excavators and aircraft.

A Practical Guide to Hydraulic Pressure Ranges

To navigate this, it's best to categorize systems by their typical operating pressure. This provides a clear framework for understanding component selection and application suitability.

Low-Pressure Systems (< 1,500 PSI / 100 bar)

These systems are characterized by simple, robust components. They are often used where space and weight are not primary concerns.

Common applications include log splitters, farm implements, and basic hydraulic presses.

Medium-Pressure Systems (1,500 - 3,000 PSI / 100 - 210 bar)

This range represents a vast number of industrial and older mobile hydraulic systems. It is a well-understood domain with a wide variety of readily available and cost-effective components.

You will find this range in factory automation, machine tools, and waste management equipment like compactors.

High-Pressure Systems (3,000 - 6,000 PSI / 210 - 420 bar)

This is the modern standard for high-performance applications, especially in mobile machinery where power density is critical.

Heavy construction equipment (excavators, loaders), modern injection molding machines, and advanced industrial presses operate in this range.

Ultra-High-Pressure (UHP) Systems (> 10,000 PSI / 700 bar)

This is a specialized field. UHP systems are used where immense force is required from a very small and often portable package.

Applications include hydraulic torque wrenches, rescue tools (e.g., "Jaws of Life"), and hydrodemolition equipment for cutting concrete.

Understanding the Trade-offs

Pushing for higher pressure provides significant benefits but also introduces critical engineering challenges and risks. Choosing the right pressure is a matter of balancing these factors.

The Benefit: Compact Power

The core advantage is power density. Doubling the pressure allows you to get the same force from a cylinder with half the piston area, leading to smaller, lighter, and often faster-actuating systems.

The Cost: Component Demands

Higher pressures demand more from every part of the system. Hoses must have more reinforcement, seals must be made from more advanced materials, and component bodies must be stronger. Tolerances become much tighter, requiring superior filtration to prevent damage.

The Risk: Safety and Maintenance

Safety is paramount. A pinhole leak in a 3,000+ PSI system can inject hydraulic fluid through skin, causing catastrophic injury. Maintenance requires stricter procedures, proper depressurization, and specialized knowledge.

Making the Right Choice for Your Goal

Your system's ideal pressure is dictated by its primary objective.

- If your primary focus is maximum power in a compact space: A high-pressure system (3,000 - 6,000 PSI) is the necessary choice, but be prepared for higher component costs and stricter maintenance.

- If your primary focus is reliability and cost-effectiveness for a stationary application: A medium-pressure system (1,500 - 3,000 PSI) often provides the best balance of performance and total cost of ownership.

- If your primary focus is simplicity and ease of maintenance: A low-pressure system (<1,500 PSI) is the most forgiving and uses the most basic, readily available components.

Understanding these pressure ranges and their associated trade-offs empowers you to select the right approach for your specific hydraulic challenge.

Summary Table:

| Pressure Range | Typical PSI | Common Applications | Key Characteristics |

|---|---|---|---|

| Low-Pressure | < 1,500 PSI | Log splitters, farm implements | Simple, robust components, cost-effective |

| Medium-Pressure | 1,500 - 3,000 PSI | Factory automation, machine tools | Balanced performance, wide component availability |

| High-Pressure | 3,000 - 6,000 PSI | Excavators, injection molding machines | High power density, requires advanced components |

| Ultra-High-Pressure (UHP) | > 10,000 PSI | Hydraulic torque wrenches, rescue tools | Specialized, extreme force from compact packages |

Need Help Selecting the Right Hydraulic System?

Choosing the correct pressure range is critical for your equipment's performance, safety, and cost-effectiveness. KINTEK specializes in providing laboratory and industrial equipment solutions, including hydraulic components tailored to your specific pressure requirements.

We can help you:

- Select components optimized for your target pressure range (low, medium, high, or UHP)

- Balance power density with reliability and maintenance needs

- Ensure safety compliance for high-pressure applications

Contact our experts today to discuss your hydraulic system goals and get a solution that delivers the right balance of power and practicality. Get in touch with KINTEK now!

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- High Purity Pure Graphite Crucible for Evaporation

- CVD Diamond for Thermal Management Applications

- Electron Beam Evaporation Coating Tungsten Crucible and Molybdenum Crucible for High Temperature Applications

People Also Ask

- Why use laboratory hydraulic presses for diamond/copper powders? Achieve Superior Green Compact Density

- What does XRF measure? Uncover Elemental Composition for Materials Analysis

- How does a laboratory hydraulic press ensure the quality of sulfide electrolyte pellets? Optimize Ion Transport

- Why is powder metallurgy limited to small parts? The Compaction & Cost Challenges Explained

- What function does a laboratory hydraulic press serve in photocatalytic pigments? | Enhance Sample Standardization

- What are the list of preventive maintenance tasks for a hydraulic system? A Proactive Guide to Maximize Uptime

- Why is a laboratory hydraulic press used for pelletizing catalysts? Ensure Stability in SMR Evaluations

- What causes hydraulics to get hot? Diagnose and Fix Overheating Issues