At its core, cryopreservation is the process of pausing biological time. It uses extremely low temperatures, often in conjunction with cryoprotective agents, to stop virtually all metabolic activity within cells and tissues. Ultra-low temperature (ULT) freezers are a cornerstone of this process, providing the stable, controlled environment required to maintain the integrity of these invaluable biological materials for long-term storage.

The fundamental challenge in cryopreservation isn't just making samples cold, but keeping them at a consistent, ultra-low temperature. ULT freezers are specifically engineered to solve this problem, preventing the subtle temperature fluctuations that can destroy samples at a microscopic level.

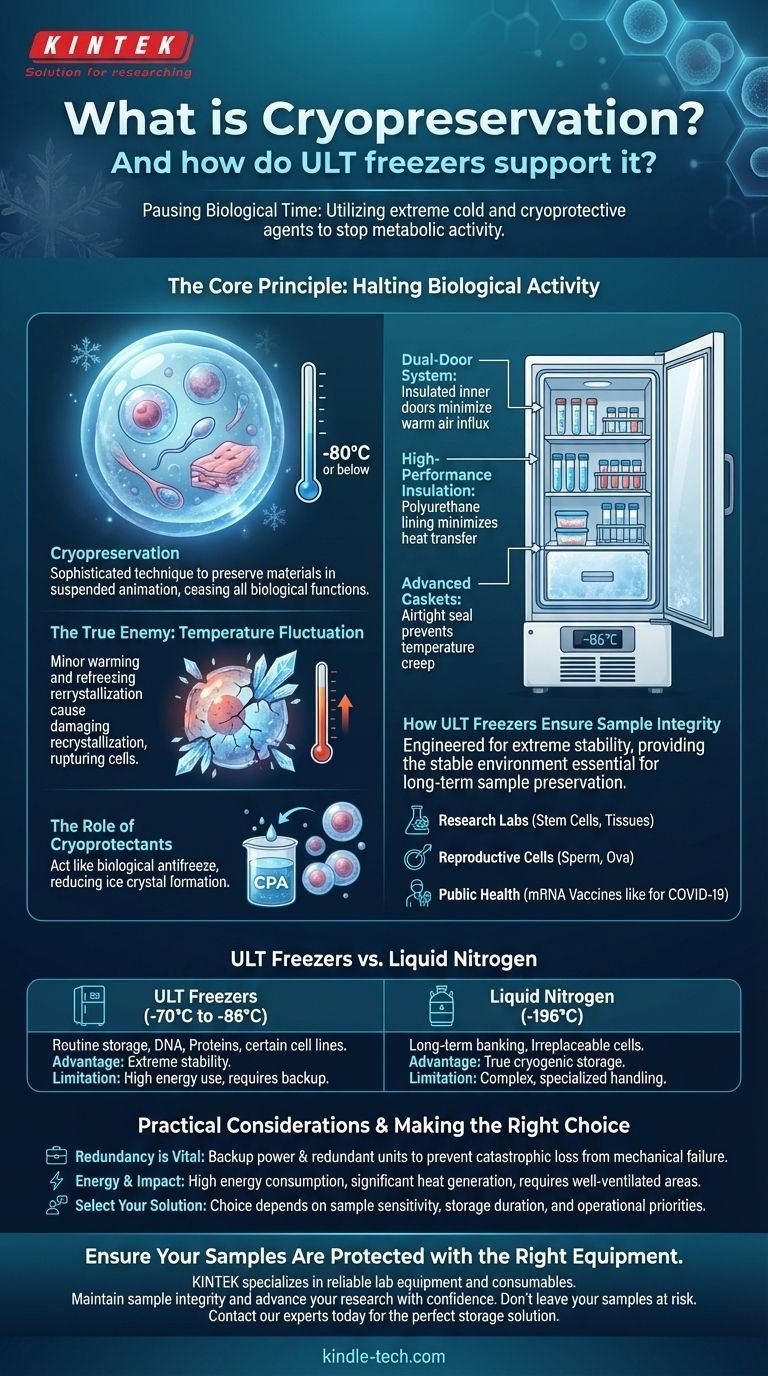

The Core Principle: Halting Biological Activity

What is Cryopreservation?

Cryopreservation is a sophisticated technique designed to preserve biological materials—such as cells, tissues, or genetic material—in a state of suspended animation. By bringing them to temperatures as low as -80°C or below, all biological functions, including the enzymatic processes that lead to degradation, effectively cease.

The True Enemy: Temperature Fluctuation

The greatest risk to a frozen sample is not the cold itself, but changes in temperature. Even minor warming and refreezing can cause microscopic ice crystals to form or grow within cells, a process called recrystallization. This can rupture cell membranes and render the sample useless.

The Role of Cryoprotectants

To mitigate the damage from initial freezing, scientists use cryoprotective agents (CPAs). These substances, like glycerol or DMSO, act like a biological antifreeze, reducing the concentration of electrolytes and preventing the formation of large, damaging ice crystals as the temperature drops.

How ULT Freezers Ensure Sample Integrity

Engineered for Extreme Stability

A ULT freezer is not simply a more powerful version of a household freezer. It is a highly engineered device designed for one purpose: stability. Features like dual-door systems, with an insulated inner door for each shelf, minimize the influx of warm air when the main door is opened.

High-performance polyurethane insulation lines the walls to minimize heat transfer from the outside environment. Advanced gaskets create an airtight seal, preventing temperature creep and reducing the workload on the cooling system.

A Controlled Environment for Critical Materials

This combination of features creates the stable, controlled environment essential for preventing sample degradation over weeks, months, or years. By maintaining a constant ultra-low temperature, ULT freezers ensure that the biological materials remain in their preserved state.

From Research Labs to Public Health

The applications are vast and critical. ULT freezers are essential for storing stem cells, reproductive cells like sperm and ova, and tissues for research. They also play a major public health role, famously providing the reliable storage required for mRNA vaccines, such as those for COVID-19.

Understanding the Trade-offs and Practical Considerations

ULT Freezers vs. Liquid Nitrogen

ULT freezers typically operate in the -70°C to -86°C range. For even longer-term storage or for extremely sensitive cell types, true cryogenic storage in liquid nitrogen (-196°C) is used. The choice depends on the sample's sensitivity, required storage duration, and lab protocol.

The Critical Need for Redundancy

Mechanical failure is the single greatest operational risk. The loss of a single ULT freezer can destroy years of research or irreplaceable clinical samples. Because of this, robust backup power systems and redundant freezer units are not a luxury but a necessity for any critical storage facility.

Energy and Environmental Impact

These freezers are energy-intensive machines that run 24/7. They consume a significant amount of electricity and generate considerable heat, requiring placement in well-ventilated areas. This operational cost and environmental footprint are key factors to consider in lab management.

Making the Right Choice for Your Goal

Selecting the correct storage method is critical for success. Your decision should be guided by the nature of your samples and your operational priorities.

- If your primary focus is routine storage of proteins, DNA, or certain cell lines: A standard -80°C ULT freezer provides an excellent and accessible solution for maintaining sample integrity.

- If your primary focus is long-term banking of irreplaceable or highly sensitive cells: True cryogenic storage in liquid nitrogen is often the required standard, though a ULT freezer may be used for temporary storage or backup.

- If your primary focus is operational reliability and risk mitigation: You must invest in backup power, temperature monitoring systems, and a clear emergency plan to protect against catastrophic sample loss.

Ultimately, mastering cryopreservation storage is about selecting the right tool to achieve the necessary level of biological stasis for your specific materials.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Primary Use | Long-term storage of cells, tissues, proteins, DNA, and vaccines. |

| Typical Temperature Range | -70°C to -86°C. |

| Main Advantage | Provides extreme temperature stability to prevent sample-damaging fluctuations. |

| Ideal For | Routine storage of research materials and critical public health supplies. |

| Key Limitation | Requires significant energy and robust backup systems to prevent sample loss. |

Ensure Your Samples Are Protected with the Right Equipment

Your research and clinical materials are invaluable. Protecting them requires reliable, high-performance lab equipment designed for critical applications like cryopreservation.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide the reliable ULT freezers and support you need to maintain sample integrity, safeguard your work, and advance your research with confidence.

Don't leave your samples at risk. Contact our experts today to find the perfect storage solution for your laboratory's specific requirements.

Visual Guide

Related Products

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples