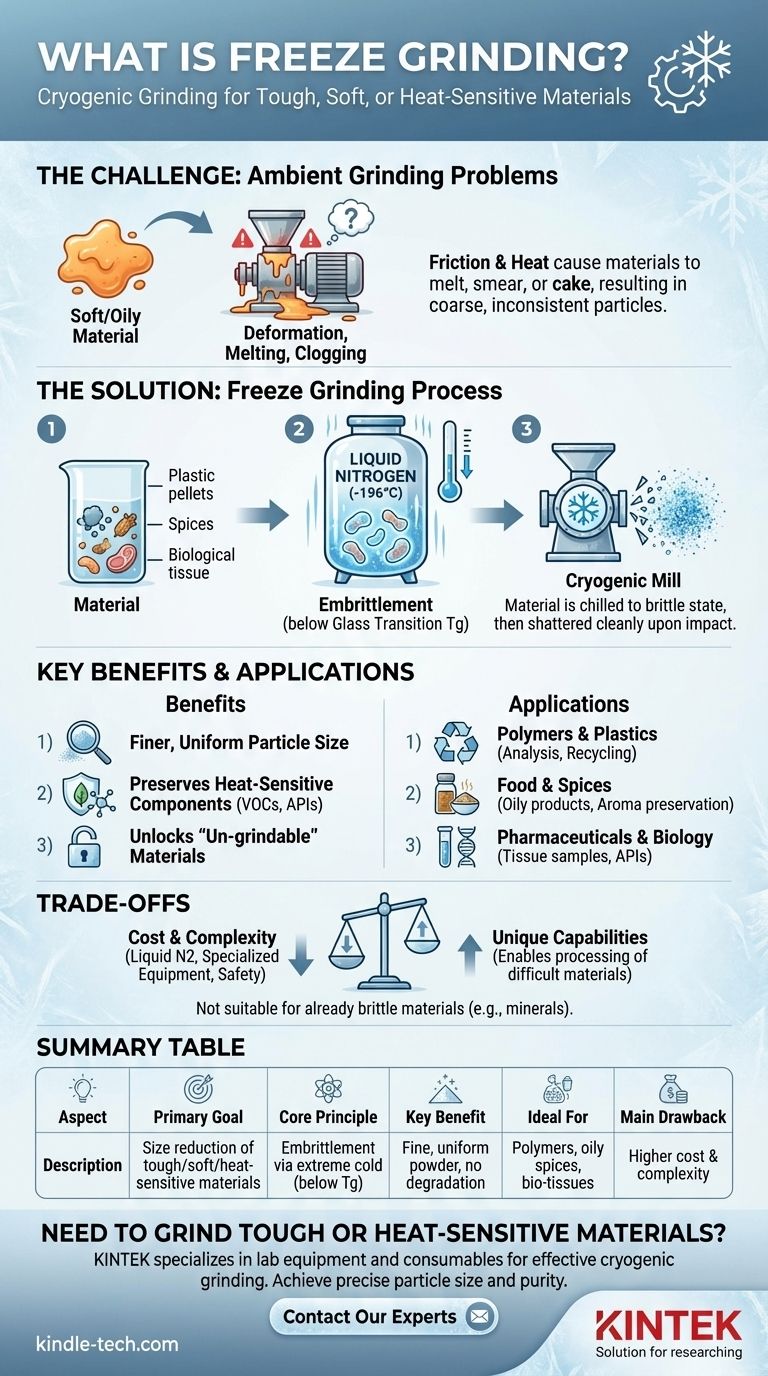

In short, freeze grinding is a process where a material is chilled to a very low temperature, typically with liquid nitrogen, and then immediately ground into a fine powder. This technique, also known as cryogenic grinding or cryomilling, makes tough, soft, or elastic materials brittle, allowing them to be shattered easily instead of smearing or melting. It is a size-reduction method, not a preservation or drying method.

The core problem with grinding soft or oily materials is that they deform, melt, or clog equipment. Freeze grinding overcomes this by using extreme cold to make the material hard and brittle, enabling a clean, precise break into a fine, uniform powder.

The Challenge: Grinding "Soft" Materials

The Problem with Ambient Grinding

Many materials are difficult to grind at room temperature. The friction and heat generated by the milling process can cause them to melt, smear, or become gummy.

This clogs screens, cakes the inside of the mill, and results in an inconsistent, coarse particle size. Materials like plastics, rubbers, oily spices, and tough biological tissues are notoriously problematic.

Ineffective Size Reduction

Instead of breaking cleanly, these pliable materials tend to deform or tear. The result is a poor-quality product that lacks the fine, free-flowing consistency required for many industrial and laboratory applications.

How Freeze Grinding Solves the Problem

The Principle of Embrittlement

Every polymer or soft material has a glass transition temperature (Tg). Below this temperature, the material loses its rubbery or leathery characteristics and becomes hard, glassy, and brittle.

Freeze grinding works by immersing the material in a cryogen, most commonly liquid nitrogen (-196°C or -321°F). This rapidly cools the material far below its Tg, inducing embrittlement.

The Grinding Mechanism

Once the material is brittle, it is fed into a mill (such as a hammer or pin mill). Instead of deforming, the now-glassy material shatters on impact, breaking cleanly along fracture lines.

This allows for a much finer and more uniform particle size than could ever be achieved at ambient temperatures.

Preserving Sensitive Components

An added benefit is the preservation of heat-sensitive components. The extreme cold protects volatile organic compounds (VOCs) in spices, active pharmaceutical ingredients (APIs), and delicate biological structures from being degraded or destroyed by the heat of grinding.

Understanding the Trade-offs

Primary Benefit: Unlocking New Possibilities

The main advantage of freeze grinding is its ability to process otherwise "un-grindable" materials. It enables the creation of fine powders from tough polymers, high-fat foods, and heat-sensitive organic matter with high precision and purity.

Key Drawback: Cost and Complexity

This is not a simple or inexpensive process. It requires a continuous supply of liquid nitrogen, insulated and specialized milling equipment, and stringent safety protocols for handling cryogens. The operational costs are significantly higher than for standard ambient grinding.

Material Suitability

Freeze grinding is a specialized solution. It offers no benefit for materials that are already hard and brittle at room temperature, such as minerals or ceramics. Its use is justified only when ambient grinding fails to produce the desired result.

How to Apply This to Your Goal

Before choosing this method, you must be clear on your material's properties and your desired outcome.

- If your primary focus is polymers and plastics: Freeze grinding is the standard for creating fine powders for lab analysis, recycling, or as additives.

- If your primary focus is food and spices: Use this method to grind oily or high-fat products (like nutmeg or flaxseed) to preserve their volatile aromas and prevent equipment fouling.

- If your primary focus is pharmaceuticals or biology: This is the ideal technique for preparing tissue samples or grinding heat-sensitive compounds without degrading their chemical integrity.

Ultimately, freeze grinding is the definitive solution when a material’s inherent toughness or sensitivity makes conventional size reduction impossible.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Goal | Size reduction of tough, soft, or heat-sensitive materials |

| Core Principle | Embrittlement by cooling below the material's glass transition temperature (Tg) |

| Key Benefit | Produces fine, uniform powder without melting, smearing, or degrading the material |

| Ideal For | Polymers, plastics, oily spices, pharmaceuticals, biological tissues |

| Main Drawback | Higher cost and complexity due to liquid nitrogen and specialized equipment |

Need to grind tough or heat-sensitive materials into a fine powder?

Freeze grinding (cryomilling) is the definitive solution for materials that melt, smear, or clog standard equipment. KINTEK specializes in lab equipment and consumables for all your laboratory needs, including solutions for effective cryogenic grinding.

We can help you achieve the precise particle size and purity your application demands. Contact our experts today to discuss how freeze grinding can solve your specific material processing challenges!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes