At its core, a frequency induction furnace is a device that uses the principles of electromagnetic induction to rapidly heat and melt conductive materials, most commonly metals. It generates an intense, fluctuating magnetic field that induces electrical currents directly within the material, causing it to heat itself from the inside out.

Unlike traditional furnaces that apply external heat, an induction furnace turns the metal charge itself into the heat source. This fundamental difference allows for unparalleled speed, energy efficiency, and precise control over temperature and alloy composition.

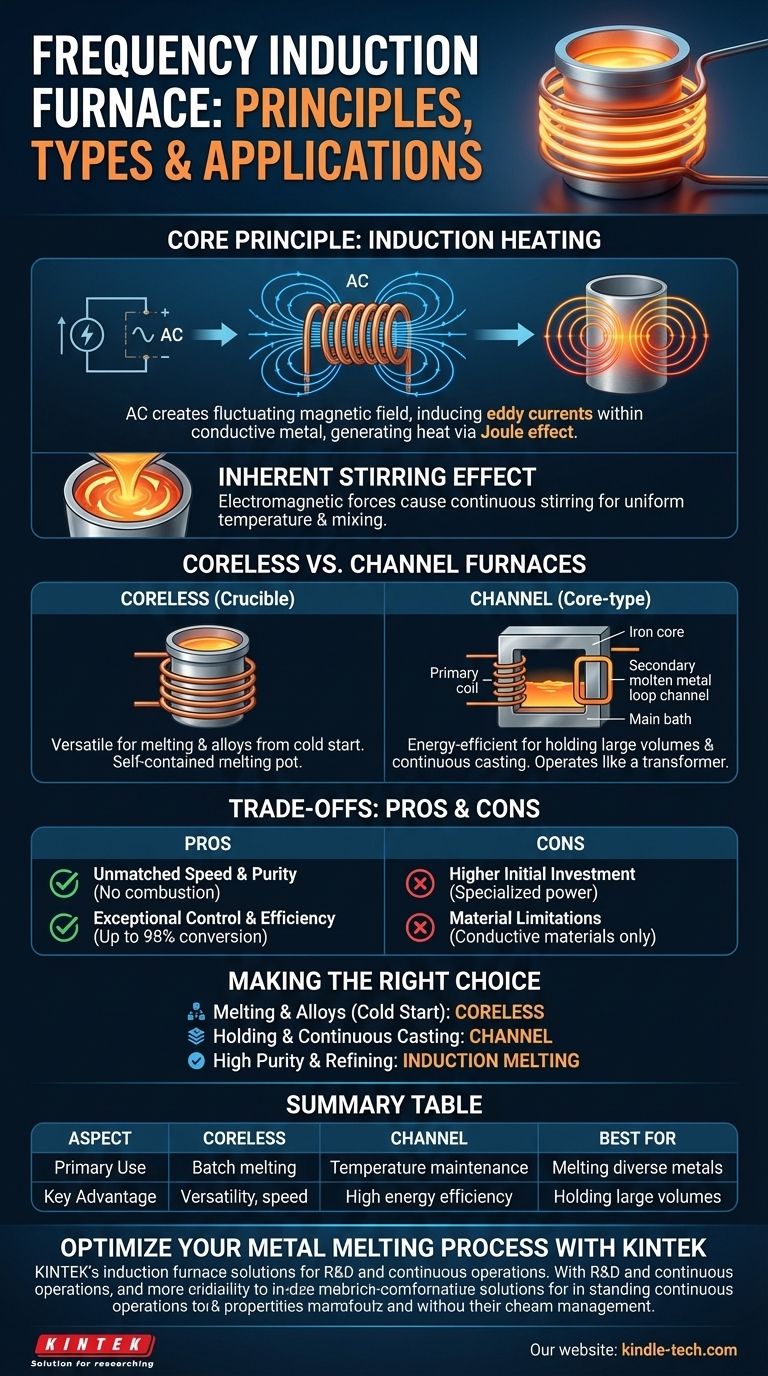

The Fundamental Principle: How Induction Heating Works

An induction furnace operates on a principle discovered by Michael Faraday in the 19th century. It translates electrical energy into thermal energy with remarkable efficiency by leveraging electromagnetism.

Creating the Magnetic Field

The process begins with a powerful alternating current (AC) sent from a specialized power supply through a copper coil. This coil, known as an inductor, is typically wrapped around the crucible or vessel holding the material to be heated.

The flow of alternating current through the coil generates a strong and rapidly changing magnetic field in the space within and around the coil.

Inducing Eddy Currents

When a conductive material, such as a metal charge, is placed within this magnetic field, the field induces circular electrical currents within the metal. These are known as eddy currents.

Generating Heat from Within

The metal has a natural resistance to the flow of these eddy currents. This resistance generates immense heat through a phenomenon called the Joule effect. Because the heat is generated inside the material, melting is extremely fast and uniform.

The Inherent Stirring Effect

The same electromagnetic forces that induce the eddy currents also exert a force on the molten metal. This causes a natural, continuous stirring action, which ensures the entire melt reaches a uniform temperature and that any added alloys are mixed thoroughly.

Coreless vs. Channel Furnaces: Two Distinct Architectures

While the principle is the same, induction furnaces are built in two primary configurations, each suited for different applications.

The Coreless (Crucible) Furnace

This is the most common design. The induction coil is formed around a non-conductive, refractory-lined crucible that contains the metal charge. It functions as a self-contained melting pot.

Coreless furnaces are highly versatile, ideal for melting a wide range of metals from a cold start and for creating precise, specialized alloys.

The Channel (Core-type) Furnace

This furnace operates much like a transformer. It uses an iron core with a primary coil, and a secondary "coil" is formed by a continuous loop of molten metal held in a channel.

Heat generated in this channel circulates into a larger bath of molten metal. Channel furnaces are extremely energy-efficient for holding large volumes of metal at a constant temperature or for melting low-temperature alloys, making them ideal for foundries with continuous casting operations.

Understanding the Trade-offs

Induction technology offers significant advantages, but it's important to recognize its specific characteristics and limitations.

Pro: Unmatched Speed and Purity

Because heat is generated internally, melting is much faster than with fuel-fired or resistance furnaces. Furthermore, since there is no combustion, there are no byproducts to contaminate the melt, resulting in a cleaner, higher-quality final product.

Pro: Exceptional Control and Efficiency

Power can be adjusted instantly, allowing for precise temperature control. The direct heating process is highly energy-efficient, with modern systems converting up to 98% of electrical energy into useful heat in the melt.

Con: Higher Initial Investment

The specialized power supply and control systems required for an induction furnace typically result in a higher upfront capital cost compared to traditional furnace types.

Con: Material Limitations

Induction heating is only effective on materials that are electrically conductive. It is not suitable for heating non-conductive materials like ceramics or certain polymers unless a conductive crucible is used to transfer heat indirectly.

Making the Right Choice for Your Application

Selecting the correct furnace type is critical for optimizing your metallurgical process. Your primary operational goal should guide your decision.

- If your primary focus is melting diverse metals and creating precise alloys from a cold start: A coreless induction furnace offers the flexibility, speed, and clean melting environment you need.

- If your primary focus is holding large volumes of molten metal at a specific temperature for casting: A channel induction furnace provides superior energy efficiency for continuous, long-term operation.

- If your primary focus is achieving high purity or refining metals: The clean, contained, and controllable nature of induction melting is ideal for specialized applications like degassing or vacuum distillation.

By understanding these core principles, you can select the precise induction technology to optimize your process for speed, efficiency, and quality.

Summary Table:

| Aspect | Coreless Furnace | Channel Furnace |

|---|---|---|

| Best For | Melting diverse metals, precise alloys from cold start | Holding large volumes of metal, continuous casting |

| Primary Use | Batch melting, alloy creation | Temperature maintenance, superheating |

| Key Advantage | Versatility, speed from cold start | High energy efficiency for holding |

Ready to Optimize Your Metal Melting Process?

At KINTEK, we specialize in providing advanced lab equipment, including high-performance induction furnaces tailored to your specific needs. Whether you require the versatility of a coreless furnace for R&D and alloy development or the efficiency of a channel furnace for continuous operations, our solutions deliver unparalleled speed, purity, and control.

Contact us today to discuss how our induction melting technology can enhance your laboratory's efficiency and product quality. Let our experts help you select the perfect system for your application.

Get in touch with our specialists now!

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary function of a vacuum induction melting furnace? Melt High-Purity Metals with Precision

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications