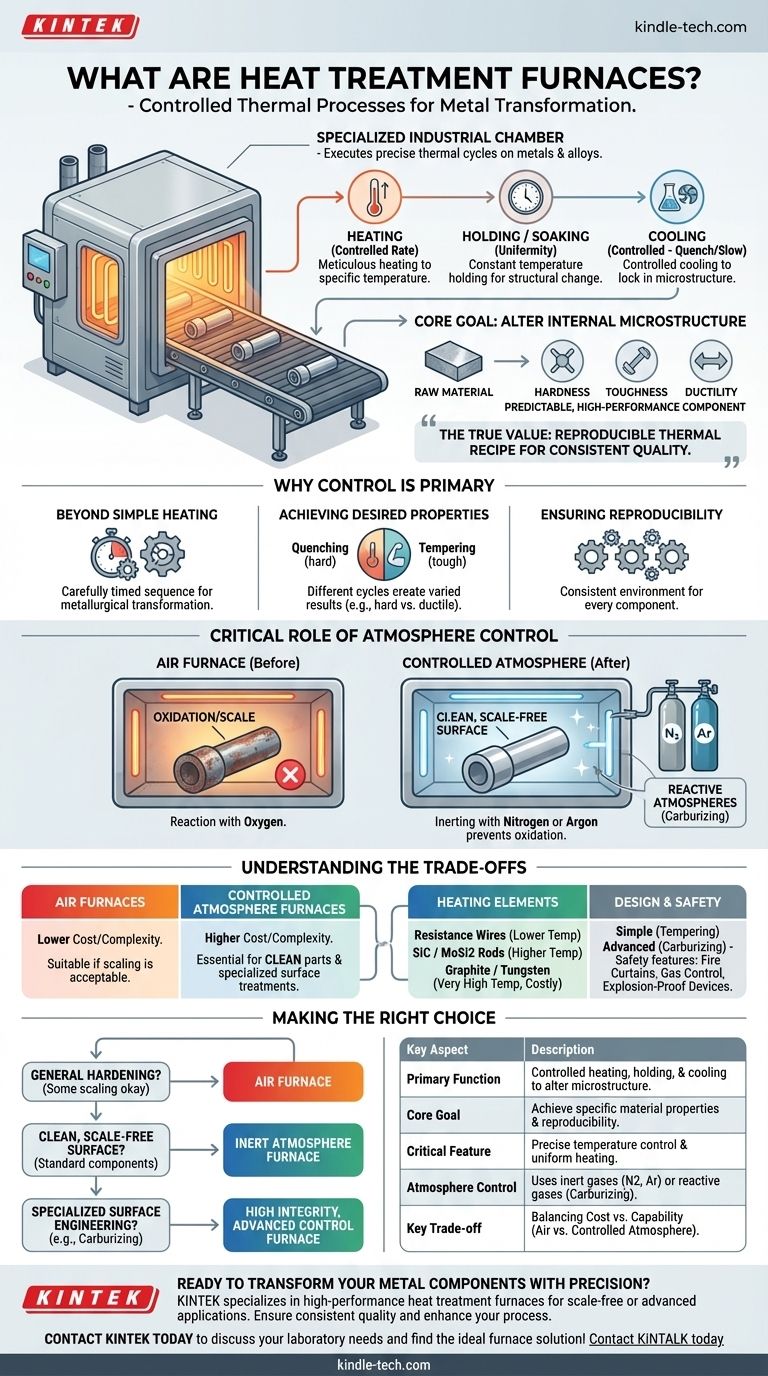

At its core, a heat treatment furnace is a specialized, high-temperature industrial chamber engineered to execute precise thermal processes on metals and alloys. Its function is not merely to heat metal, but to meticulously control the entire cycle of heating, holding at a specific temperature, and cooling. This controlled process alters the material's internal microstructure to achieve desired properties like hardness, toughness, or ductility.

The true value of a heat treatment furnace lies in its ability to deliver a reproducible thermal recipe. It transforms a raw material into a predictable, high-performance component by ensuring that every part receives the exact same treatment, guaranteeing consistent quality and performance.

Why Control is the Primary Goal

The term "furnace" can be misleading, suggesting simple, brute-force heat. In heat treatment, precision is everything. The furnace is an instrument for controlling a metallurgical transformation.

Beyond Simple Heating

A heat treatment process is a carefully timed sequence. It involves a rapid or slow heating rate to a specific temperature, a "soak" period where the temperature is held constant to ensure uniformity, and a controlled cooling phase (quenching or slow cooling) that locks in the new microstructure.

Achieving Desired Properties

Different thermal cycles produce vastly different results. For example, a rapid cool (quenching) can make steel extremely hard, while a subsequent, lower-temperature treatment (tempering) reduces brittleness and adds toughness. Other processes like carburizing add carbon to the surface of a part to create a hard, wear-resistant outer layer.

Ensuring Reproducibility

In manufacturing, consistency is paramount. A heat treatment furnace provides the controlled environment needed to ensure that the thousandth component has the exact same properties as the first. This is achieved through uniform temperature distribution and precise cycle automation.

The Critical Role of Atmosphere Control

When metals are heated to high temperatures, they react readily with the oxygen in the air, a process called oxidation. This forms a layer of scale on the surface, which can damage the component's finish and dimensions.

Preventing Oxidation and Contamination

To prevent this, many heat treatment furnaces operate with a controlled atmosphere. The air inside the furnace is replaced with a specific gas or mixture of gases that will not react with the hot metal.

Using Inert Atmospheres

The most common method is inerting, which involves purging the furnace with a non-reactive gas like nitrogen or argon. This blanket of inert gas protects the component from oxygen and water vapor, ensuring a clean, scale-free surface upon completion.

Enabling Specific Processes

Some advanced processes require a reactive atmosphere. In carburizing, for instance, the atmosphere is intentionally rich in carbon, which diffuses into the surface of the steel. This requires furnaces with exceptionally high sealing integrity to maintain the precise gas composition.

Understanding the Trade-offs

Choosing or specifying a heat treatment furnace involves balancing capability, complexity, and cost. There is no single "best" furnace; the right choice depends entirely on the application.

Atmosphere vs. Air Furnaces

A simple furnace that heats in normal air is less complex and cheaper to build and operate. However, it is only suitable for processes where surface oxidation is acceptable or can be removed later. Controlled atmosphere furnaces are more expensive and complex but are essential for producing clean parts or performing specialized surface treatments.

Heating Element Selection

The choice of heating element dictates the furnace's maximum operating temperature and cost.

- Resistance wires are common for lower temperatures.

- Silicon carbide or silicon molybdenum rods are used for higher temperature applications.

- Graphite or tungsten elements are required for very high-temperature or vacuum furnaces but come at a significantly higher cost and have specific atmospheric requirements.

Design and Safety Features

A furnace for a simple tempering process will have different requirements than one for carburizing. The latter requires anti-carburizing insulation bricks, advanced gas control panels, and safety features like fire curtains and explosion-proof devices to safely manage the flammable atmosphere gases.

Making the Right Choice for Your Goal

The furnace must be matched to the metallurgical objective. The process dictates the tool.

- If your primary focus is general-purpose hardening or stress relief where some scaling is acceptable: A simpler, cost-effective air furnace may be sufficient for the task.

- If your primary focus is producing a clean, scale-free surface on standard components: A furnace with a reliable nitrogen or argon inerting system is the correct choice.

- If your primary focus is performing specialized surface engineering like carburizing: A furnace with high sealing integrity, advanced atmosphere controls, and comprehensive safety systems is non-negotiable.

Ultimately, understanding the furnace's capabilities is key to transforming a simple piece of metal into a precisely engineered component.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Controlled heating, holding, and cooling of metals to alter microstructure. |

| Core Goal | Achieve specific material properties (hardness, toughness) and ensure reproducibility. |

| Critical Feature | Precise temperature control and uniform heating. |

| Atmosphere Control | Uses inert gases (Nitrogen, Argon) to prevent oxidation or reactive gases for processes like carburizing. |

| Key Trade-off | Balancing cost and complexity: Air furnaces vs. Controlled Atmosphere furnaces. |

Ready to Transform Your Metal Components with Precision?

Choosing the right heat treatment furnace is critical for achieving the exact material properties your application demands. KINTEK specializes in providing high-performance lab equipment, including heat treatment furnaces tailored to your specific metallurgical goals—whether you need scale-free surfaces with inert atmospheres or advanced capabilities for carburizing.

Let us help you ensure consistent quality and enhance your manufacturing process.

Contact KINTALK today to discuss your laboratory needs and discover the ideal furnace solution for your projects!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials

- What are the methods of brazing heating? Choose the Right Method for Your Production Needs

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance