In short, a high-frequency induction heater is a specialized tool that uses a high-frequency alternating magnetic field to generate intense heat very quickly and precisely on the surface of a conductive material. The critical principle is that the higher the frequency, the shallower the heat penetration. This makes it the ideal solution for processes that require treating only the exterior of a part while leaving the core unaffected.

The choice between high and low-frequency induction heating is fundamentally a choice of where you want the heat to be generated. High frequency concentrates energy on the surface for tasks like case hardening, while low frequency drives heat deep into a part for processes like forging.

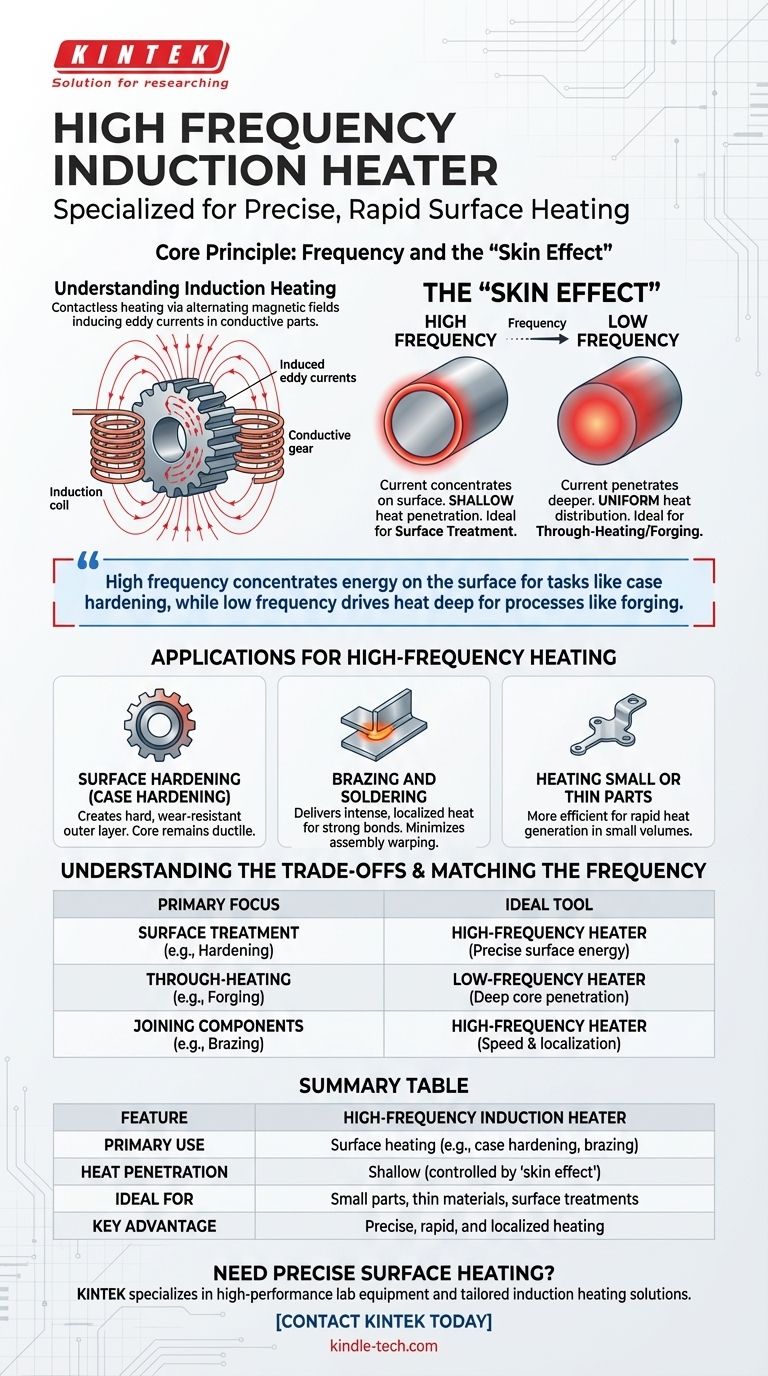

The Core Principle: Frequency and the "Skin Effect"

To understand why high-frequency heating is so effective for specific tasks, we must first grasp the underlying physics that govern the process.

Understanding Induction Heating

Induction heating works without any physical contact. An induction coil generates a powerful, rapidly alternating magnetic field. When a conductive part (like a steel gear) is placed within this field, it induces electrical currents, called eddy currents, to flow within the part. The material's natural resistance to these currents generates precise and instantaneous heat.

Introducing the "Skin Effect"

A fundamental principle of electromagnetism is the "skin effect." It describes the tendency of an alternating electric current (AC) to become distributed within a conductor so that the current density is largest near the surface and decreases with greater depths.

How Frequency Governs Heat Depth

The frequency of the alternating current is the primary control for the skin effect's intensity. This relationship is the most important concept in induction heating.

- High Frequency: A very high-frequency current concentrates almost exclusively in a thin layer on the material's surface. This allows for rapid, targeted heating of the exterior "skin" of the part.

- Low Frequency: A lower frequency current is not as constrained by the skin effect and can therefore penetrate much deeper into the material, heating it more uniformly from the surface to the core.

Applications for High-Frequency Heating

The ability to heat only the surface of an object unlocks several critical industrial applications where altering the entire part would be detrimental.

Surface Hardening (Case Hardening)

This is the most common application. By rapidly heating the surface of a steel part (like a gear tooth or bearing) above its transformation temperature and then quickly quenching it, you create a very hard, wear-resistant outer layer. The core of the part remains softer and more ductile, allowing it to absorb shock and impact without fracturing.

Brazing and Soldering

High-frequency induction is ideal for joining components. It can deliver intense, localized heat to a joint, melting the filler material to create a strong bond without heating and potentially warping the entire assembly.

Heating Small or Thin Parts

For small or thin-walled parts, a high frequency is more efficient at generating heat quickly. A lower frequency might pass through the part with less effect, resulting in an inefficient heating cycle.

Understanding the Trade-offs

While powerful, a high-frequency heater is not a universal solution. Choosing the wrong frequency for the job leads to poor results and inefficiency.

Limited Heat Penetration

The primary advantage of high-frequency heating is also its main limitation. It is the wrong tool for applications that require heating a large, thick object all the way through, such as preparing a large steel billet for forging.

Equipment and Coil Design

The operating frequency dictates the design of the power supply and the induction coil. High-frequency systems are optimized for precision and surface work, and their components are not interchangeable with low-frequency systems designed for bulk heating.

Matching the Frequency to Your Goal

Selecting the right induction heating process begins with a clear understanding of your desired outcome.

- If your primary focus is surface treatment like case hardening: A high-frequency heater is the definitive tool, as it concentrates energy precisely where it's needed on the surface.

- If your primary focus is through-heating large parts for forging: You must use a low-frequency heater to ensure the heat penetrates deep into the material's core for uniform temperature.

- If your primary focus is joining components via brazing: High frequency provides the necessary speed and precise localization of heat to create a strong joint without damaging the surrounding assembly.

Ultimately, mastering the induction process comes from understanding that frequency gives you direct control over the depth of the heat.

Summary Table:

| Feature | High-Frequency Induction Heater |

|---|---|

| Primary Use | Surface heating (e.g., case hardening, brazing) |

| Heat Penetration | Shallow (controlled by the 'skin effect') |

| Ideal For | Small parts, thin materials, surface treatments |

| Key Advantage | Precise, rapid, and localized heating |

Need precise surface heating for hardening, brazing, or thin parts? KINTEK specializes in high-performance lab equipment, including induction heating solutions tailored to your specific material and process requirements. Our experts can help you select the perfect system to improve efficiency and results. Contact KINTEK today to discuss your application!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis