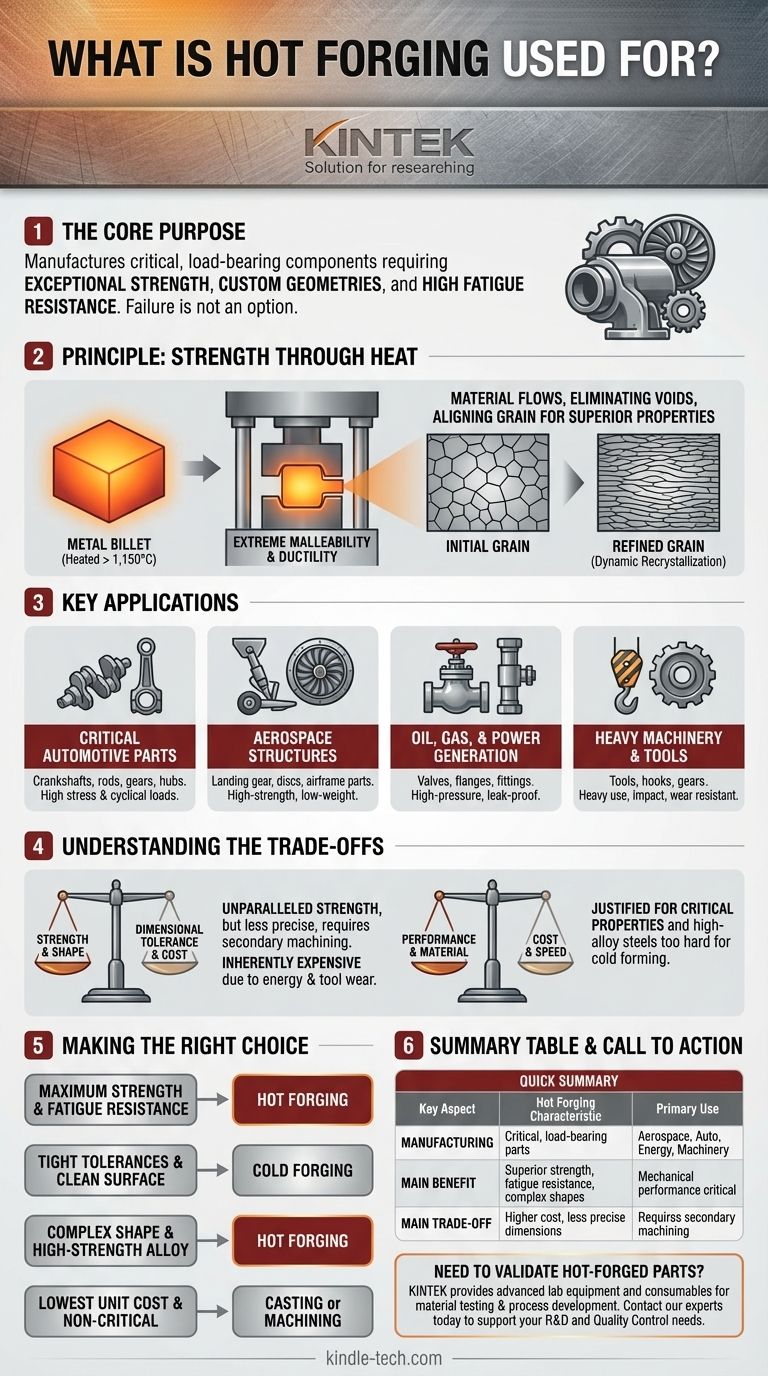

In short, hot forging is used to manufacture metal components that require exceptional strength, custom geometries, and high fatigue resistance. It is the preferred method for creating critical, load-bearing parts where failure is not an option, such as in the aerospace, automotive, and oil & gas industries.

The core decision to use hot forging is a trade-off: you accept a higher cost and less precise initial dimensions in exchange for superior material strength, ductility, and the ability to form complex shapes that other processes cannot achieve.

The Core Principle of Hot Forging: Strength Through Heat

Hot forging involves heating a metal billet above its recrystallization temperature, which can exceed 1,150°C (2,100°F) for steel. This extreme heat is the key to the process's unique benefits.

How Heat Unlocks Material Potential

Heating a metal to this point makes it extremely malleable and ductile. This allows it to be shaped with powerful presses or hammers without inducing significant strain or "work hardening" in the material.

The material flows like a dense fluid, allowing it to fill every detail of the forging die.

The Result: A Refined and Tough Component

As the metal is deformed, its internal grain structure is broken down and reformed into finer, more uniform grains. This process, known as dynamic recrystallization, eliminates voids and aligns the grain flow with the shape of the part.

This refined and continuous grain structure is the source of the exceptional strength, ductility, and resistance to impact and fatigue that defines a hot-forged component.

Creating Complex Geometries

Because the heated material deforms so easily, hot forging can produce parts with intricate shapes and significant changes in cross-section.

This makes it possible to create near-net-shape parts that would be prohibitively expensive or physically impossible to machine from a solid block of raw material, dramatically reducing material waste.

Where Hot Forging is Applied

You will find hot-forged components in the most demanding environments where mechanical performance is the primary design driver.

Critical Automotive Parts

Components like crankshafts, connecting rods, gears, and wheel hubs are constantly subjected to immense stress and cyclical loads. Hot forging provides the durability and fatigue life required for safe and reliable operation.

Aerospace Structures

The aerospace industry relies heavily on hot forging for high-strength, low-weight components like landing gear, turbine discs, and structural airframe parts made from aluminum, titanium, and nickel superalloys.

Oil, Gas, and Power Generation

Valves, flanges, and fittings used in high-pressure environments must be leak-proof and resistant to failure. Hot forging provides the dense, void-free material structure needed to contain extreme pressures safely.

Heavy Machinery and Tools

High-strength hand tools, crane hooks, and gears for industrial machinery are often hot-forged to ensure they can withstand repeated heavy use, high impacts, and abrasive wear.

Understanding the Trade-offs

Choosing hot forging is a strategic decision that requires weighing its benefits against its limitations.

Strength vs. Dimensional Tolerance

Hot forging produces unparalleled strength, but the process is less precise than cold forging. As the part cools, it can warp, and a layer of scale (oxidation) forms on the surface.

This means hot-forged parts almost always require secondary machining to achieve tight tolerances and a smooth surface finish. Cold forging, by contrast, offers excellent dimensional accuracy right out of the die.

Cost vs. Performance

The process is inherently expensive. Significant energy is required to heat the material and the dies. Furthermore, the high temperatures cause faster wear on the tooling.

This cost is justified only when the mechanical properties of the final part are absolutely critical and cannot be achieved through less expensive methods like casting or cold forging.

Material Choice

Hot forging is one of the few processes that can effectively shape high-alloy steels and superalloys that are too hard and brittle to be formed cold. If your design requires these advanced materials, hot forging is often the only viable option.

Making the Right Choice for Your Goal

Select your manufacturing process based on the most critical requirement for your component.

- If your primary focus is maximum strength and fatigue resistance: Hot forging is the definitive choice for creating parts with the highest possible structural integrity.

- If your primary focus is tight tolerances and a clean surface finish: Consider cold forging, as it provides a near-net shape with less need for secondary machining.

- If your primary focus is creating a highly complex shape from a high-strength alloy: Hot forging provides the necessary material flow to form intricate parts that other methods cannot produce.

- If your primary focus is lowest unit cost for non-critical components: Casting or machining from standard bar stock may be a more economical solution.

Understanding these fundamental trade-offs empowers you to select the manufacturing process that precisely aligns with your design's performance and budget requirements.

Summary Table:

| Key Aspect | Hot Forging Characteristic |

|---|---|

| Primary Use | Manufacturing critical, load-bearing components |

| Key Industries | Aerospace, Automotive, Oil & Gas, Heavy Machinery |

| Main Benefit | Superior strength, fatigue resistance, and complex shape capability |

| Main Trade-off | Higher cost and less precise dimensions, requiring secondary machining |

| Ideal For | Parts where mechanical performance is the primary design driver |

Need to manufacture a critical, high-strength component? KINTEK specializes in providing the advanced lab equipment and consumables necessary for material testing and process development in metal forming. Whether you're in R&D or quality control, our solutions help you validate the properties of hot-forged parts. Contact our experts today to discuss how we can support your laboratory's needs in materials science and manufacturing.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why does SEM need gold coating? Prevent Charging & Get Crisp Images

- Does strain hardening affect conductivity? Understanding the Strength vs. Conductivity Trade-Off

- Why is plasma used in sputtering? To Generate High-Energy Ions for Superior Thin Film Deposition

- Is plastic pyrolysis oil better than diesel? A Practical Guide to Waste-to-Energy Fuel

- What is a sintered metal? A Guide to High-Strength, Complex Metal Parts

- What is film uniformity? The Key to Consistent Device Performance and Yield

- Why KBr is used in FTIR system? The Key to Accurate Mid-IR Spectral Analysis

- How does a sputter coater work? A Guide to Atomic-Level Thin Film Deposition