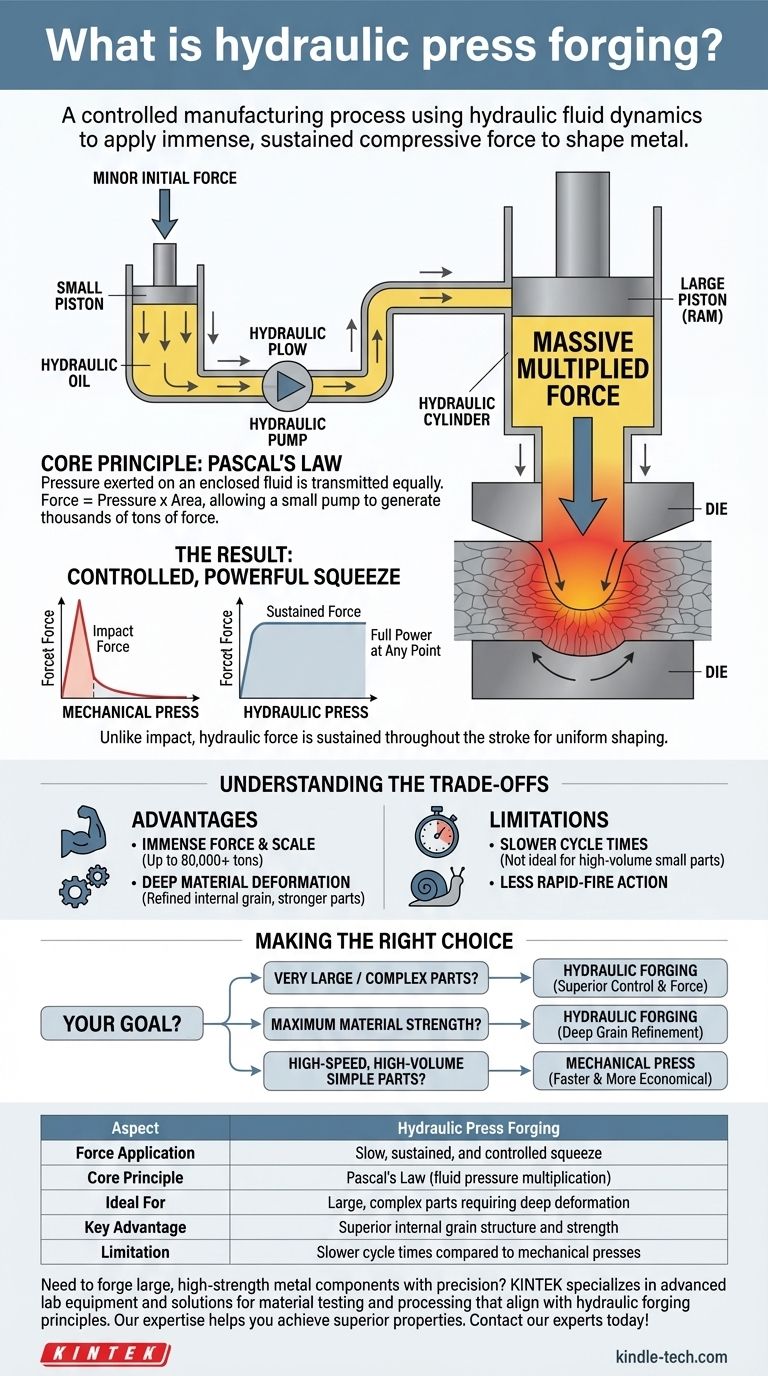

In essence, hydraulic press forging is a manufacturing process that uses a hydraulic press to apply a slow, sustained, and highly controlled compressive force to shape metal. Unlike a hammer that delivers a sudden impact, a hydraulic press uses the principle of fluid dynamics to generate immense pressure, squeezing the workpiece into its final shape within a die.

The core takeaway is that hydraulic forging is not about speed or impact; it's about deliberate and powerful control. It leverages an incompressible fluid to multiply a small initial force into a massive, sustained squeeze, making it ideal for creating large, complex parts with excellent internal structural integrity.

The Core Principle: How Force is Multiplied

Hydraulic forging operates on a fundamental law of physics discovered in the 17th century. Understanding this principle is key to understanding the entire process.

Pascal's Law in Action

The entire system is based on Pascal's Law, which states that pressure exerted on an enclosed fluid is transmitted equally and undiminished throughout that fluid.

Imagine two connected cylinders, one small and one large, both filled with oil. Pushing down on the small piston with a minor force creates pressure in the oil. This same pressure is then applied to the entire surface of the large piston, or ram.

Because the ram has a much larger surface area, the resulting force is magnified enormously (Force = Pressure x Area). This mechanical advantage allows the press to generate thousands of tons of force from a relatively simple hydraulic pump.

The Key Components

A hydraulic press consists of a few critical parts working in concert.

A hydraulic pump provides a flow of fluid (typically oil) to the system. This high-pressure fluid is forced into a hydraulic cylinder, where it pushes against a piston.

This action drives the ram downwards, exerting a constant and controllable force on the workpiece placed between the dies. Some systems use a hydraulic accumulator to store high-pressure liquid, releasing it when a strong, rapid thrust is needed.

The Result: A Controlled, Powerful Squeeze

The defining characteristic of hydraulic forging is the nature of its force application. The pressure is built up and sustained throughout the ram's entire stroke.

This is fundamentally different from a mechanical press, which delivers maximum force only at the bottom of its stroke. The hydraulic press's full power is available at any point, allowing for the complete and uniform shaping of the metal.

Understanding the Trade-offs

No single forging method is perfect for every application. The slow, controlled nature of hydraulic pressing creates a distinct set of advantages and limitations.

Advantage: Immense Force and Scale

Hydraulic presses are capable of generating enormous force, with capacities ranging from a few hundred tons to over 80,000 tons. This makes them the go-to choice for forging massive workpieces, such as structural components for aircraft or power generation turbines.

Advantage: Deep Material Deformation

The slow, sustained squeeze allows the force to penetrate deep into the material. This is highly effective for "working" the metal, refining its internal grain structure, and eliminating internal voids. The result is a stronger, more durable final part.

Limitation: Slower Cycle Times

The primary trade-off is speed. Building and releasing hydraulic pressure is inherently slower than the rapid-fire action of a mechanical press or a drop hammer. This makes it less suitable for high-volume production of smaller, simpler components where speed is the top priority.

Making the Right Choice for Your Goal

Selecting a forging method depends entirely on the specific requirements of the final product, including its size, complexity, and desired material properties.

- If your primary focus is forging very large or complex components: The immense and controllable force of a hydraulic press is the superior choice.

- If your primary focus is maximum material strength and internal quality: The deep, penetrating pressure of hydraulic forging provides unparalleled grain refinement.

- If your primary focus is high-speed, high-volume production of simple parts: A faster mechanical press is often the more economical and efficient solution.

Ultimately, hydraulic press forging is the definitive choice when precision control and deep material transformation are more critical than raw production speed.

Summary Table:

| Aspect | Hydraulic Press Forging |

|---|---|

| Force Application | Slow, sustained, and controlled squeeze |

| Core Principle | Pascal's Law (fluid pressure multiplication) |

| Ideal For | Large, complex parts requiring deep material deformation |

| Key Advantage | Superior internal grain structure and strength |

| Limitation | Slower cycle times compared to mechanical presses |

Need to forge large, high-strength metal components with precision? KINTEK specializes in advanced lab equipment and consumables, including solutions for material testing and processing that align with hydraulic forging principles. Our expertise helps you achieve superior material properties and consistent results. Contact our experts today to discuss how we can support your laboratory's forging and material science needs!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System